How To Remove Clutch Pedal Spring

Comments

-

My memory of this is that you need a good pair of vice grips and to postion yourself where you can get a good grip and apply the pressure needed to unhook it. Definitely wear some eye protection and always make sure that you have the car held up with a good set of jack stands. I always shove a few blocks under here and there for good measure. A stepdown would squash you good if it came off of the jacks. Safety 1st!0

-

First you need a stainless steel table knife that won't be missed, then grind the rounded end to a flat at about 45° to the back of the knife.

Use the knife as a lever on the RH end of the spring. Slip it between the top of the bracket and the spring so that the 45° tip lodges up against the chassis rail behind the bracket.0 -

I used a small 'come-along' winch anchored somewhere in the back near the leaf spring with the 'moving' end of the winch cable wired to the rear hook on the spring to safely extend the spring a little bit more and it easily came off at that point. Installation using this method was also a snap. Prying springs is something I usually try to avoid. You're right it is a very strong spring. Good Luck.0

-

Bryan the attached image is taken from the HUDSON Mechanical Proceedures Manual... the image shows the recommended tool to remove the spring. Good Luck and be safe.0

-

Good post! I'm trying to put my spring on, but can't pull it out by hand.0

-

Nevada Hudson wrote:Good post! I'm trying to put my spring on, but can't pull it out by hand.

Put some more oats in the porridge!0 -

Geoff C., N.Z. wrote:Put some more oats in the porridge!

Or more Steinlager!0 -

Nevada Hudson wrote:Good post! I'm trying to put my spring on, but can't pull it out by hand.

Here is an old idea an old guy has done and said it worked easily for him. He took quarters and inserted one in between each coil one at a time, one on this side and the next on the opposite side until the spring was extended far enough to fit. Then remove the quarters one at a time. Richie.0 -

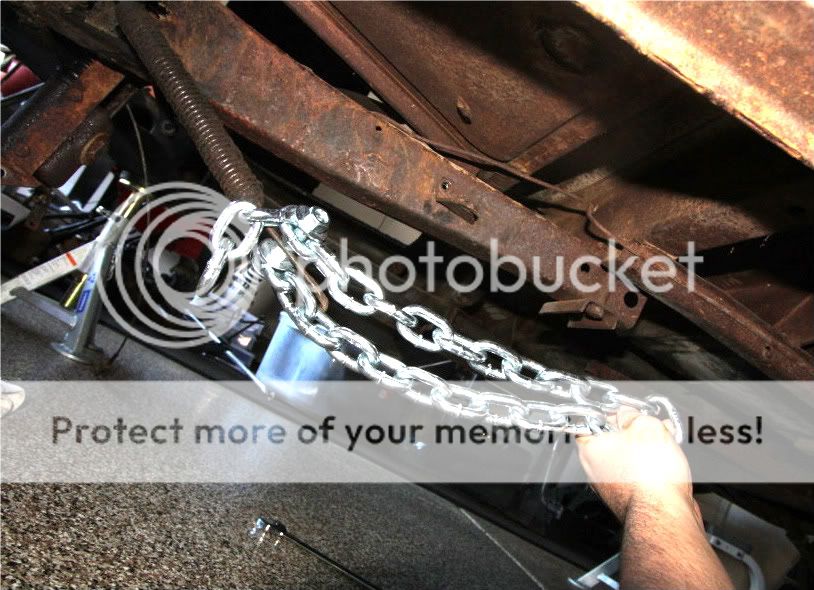

I finally got back to business and made my own spring puller. Very high tech.

It cost about $8 in supplies from Home Depot.

It cost about $8 in supplies from Home Depot.

I basically looked for the largest bolt that I could get a chain around.

Then I notched it to the diameter of the spring wire with my Dremel. (took about 4 minutes).

Then I tightened the nuts down on the spring.

Adjust the Chain length as needed.

Use a crow bar through the chain.

It was so easy.

Thanks for all the ideas. Looking at the factory tool gave me the idea how to clamp to the spring.

Then I figured having the chain on both sides of the clamped spring would help avoid a twisting torque.

I liked the idea of the quarters, and that might work well. In the beginning I was able to wedge some flat-blade scrapers into the coils of the spring to slightly extend it. I remember thinking "If I only had 20 more scrapers".

Thanks again,

Bryan0

This discussion has been closed.

Categories

- 37K All Categories

- 115 Hudson 1916 - 1929

- 21 Upcoming Events

- 94 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 180 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 77 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos