Getting ready to go cross country...

And my 308 is going to act up now. Going through my 49 C8 with a 55 Twin-H 308 and

3 sp/OD for a run next week from Fl. to Tn where its going on a buddies trailer for

the ride to Vegas for the Viva Las Vegas show and then taking our time exploring Rt

66 in the Hudson on our return.

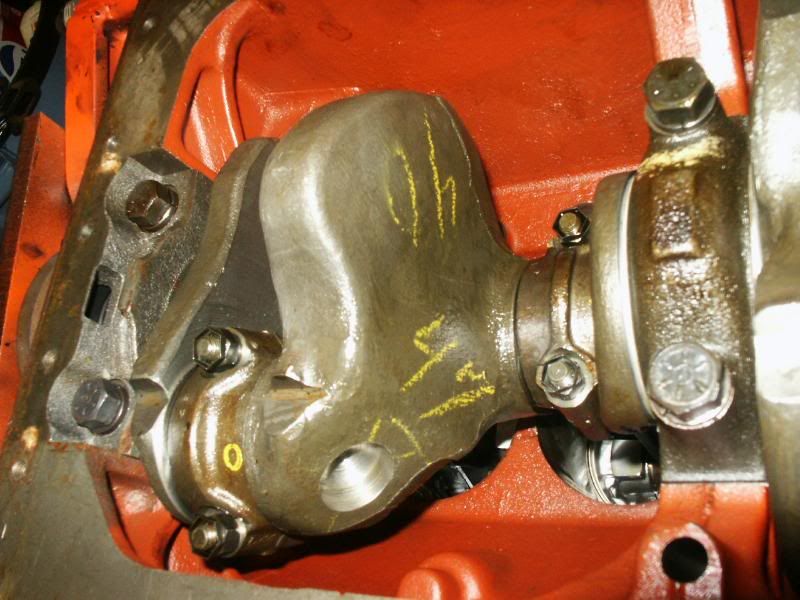

My 308 has a Clifford head and split header and has had a little puff out one of

the pipes for a little while now that really hasn't affected driveability, just

noticeable at idle and an aggravation. Well,I figured a little attention and good

tune-up would bring her back to her sweet self,but I guess thats not to be,at least

right now. Here's what I found.

CYL Cranking Compression CYL leakage

(cold) (cold)

#1 160 psi 62/80

#2 160 psi 64/80

#3 165 psi 63/80

#4 160 psi 46/80

#5 120 psi 20/80

#6 145 psi 32/80

Well poop, 5 and 6 are both leaking past the intake valve and I see a rapid 2 inch

flutter on the vacuum guage as well at idle. No time to do a proper valve job before

next Fri. so just going to wing it with the new carbs and a tune. Experience has

taught me that if there was going to be a valve problem I'd see it on the exhaust

side first so I'm a little stumped till I get into it on what the intake issue is.

This car came out of an estate sale in MI so I really have no history on the engine

other than what I've learned here that its a 55 308 (K285) casting date,stamped

F16170 that had the forward dipstick location (but uses a Chevy dipstick moved back

for the stepdown pan). I've also learned here that there is no adjustment for the

hydraulic lifters so I'll look for a preload spec for them when I get into it and

see what I've got presently.

This car also came with an extra "late" 308 and no history that is fitted with new

pistons and a fresh bore and seemingly rebuilt but minus timing set and cover and

head and pan not installed. Just not comfortable right now with more unknowns,maybe

I'll give this one a harder look when I get back.

Enough rambling for tonight. Wish me luck(or tell me I'm crazy).

3 sp/OD for a run next week from Fl. to Tn where its going on a buddies trailer for

the ride to Vegas for the Viva Las Vegas show and then taking our time exploring Rt

66 in the Hudson on our return.

My 308 has a Clifford head and split header and has had a little puff out one of

the pipes for a little while now that really hasn't affected driveability, just

noticeable at idle and an aggravation. Well,I figured a little attention and good

tune-up would bring her back to her sweet self,but I guess thats not to be,at least

right now. Here's what I found.

CYL Cranking Compression CYL leakage

(cold) (cold)

#1 160 psi 62/80

#2 160 psi 64/80

#3 165 psi 63/80

#4 160 psi 46/80

#5 120 psi 20/80

#6 145 psi 32/80

Well poop, 5 and 6 are both leaking past the intake valve and I see a rapid 2 inch

flutter on the vacuum guage as well at idle. No time to do a proper valve job before

next Fri. so just going to wing it with the new carbs and a tune. Experience has

taught me that if there was going to be a valve problem I'd see it on the exhaust

side first so I'm a little stumped till I get into it on what the intake issue is.

This car came out of an estate sale in MI so I really have no history on the engine

other than what I've learned here that its a 55 308 (K285) casting date,stamped

F16170 that had the forward dipstick location (but uses a Chevy dipstick moved back

for the stepdown pan). I've also learned here that there is no adjustment for the

hydraulic lifters so I'll look for a preload spec for them when I get into it and

see what I've got presently.

This car also came with an extra "late" 308 and no history that is fitted with new

pistons and a fresh bore and seemingly rebuilt but minus timing set and cover and

head and pan not installed. Just not comfortable right now with more unknowns,maybe

I'll give this one a harder look when I get back.

Enough rambling for tonight. Wish me luck(or tell me I'm crazy).

0

Comments

-

TwinH

That sure is a pretty engine. I'm sorry you are having leaking valve problems. I knew the 56 engines had hydrolic cam and lifters. Did someone put a 56 cam and lifters in you 55 engine? I'm pretty sure the 55 originally came with mechanical cam and lifters.

It sounds like you are going to have a very interesting cross country trip. Have a good time.

I hope you keep us informed about your trip and that it will be trouble free.

Lee O'Dell0 -

Make sure you got your WTN roster with you.

Hudsonly,

Alex Burr

Memphis, TN0 -

The '55 engine had solid lifters, the '56 was the only engine to be equipped with hydraulic lifters (from the factory). Did some very late 55s have hydraulics? - maybe because usually auto makers will transition from one form to another before an actual year change. Early Corvettes were notorious for this. Anyway, the hydraulics do have a preload and it must be set by grinding either the valve tip or the seating surface of the valve, the range is .040 - .080 with the valve compressed against the seat. The lifters are the same as the early MOPAR style. If they get clogged up, I suspect they can keep a valve open a bit. If the engine is a 55 and has hydraulics, hopefully the cam is right. The 56 cam was a reground 7X flat top designed to be used with the hydraulic lifters, the 55 solid lifter cam is the tried and true 306344 cam.0

-

Well,now that you mention hydraulics being 56 only I've always @SSumed they were

hydraulic because it has -0- valve noise that I'd associate with a solid lifter.

Truth is,I've never had the covers off. I thought the stamped "F"on the deck made

it a 55 but yes the casting date is late Nov. 55(K285)so possibly? a 56 model.

Looked at my other engine and casting date is D145(April 14,1955) and F8697 stamped

on the deck but its laying on the cam side so I didn't get a look at the lifters.

I think I'll be fine till I get back and have time to do it properly. I have lots

of faith in the old girl and we've been on a 2800 mile roadtrip a few years back

with no issues so we'll see how it shakes out (crossing fingers) And yes,I keep a

roster in the trunk and not afraid to use it...I'll update this thread as time

permits, once I'm on the road0 -

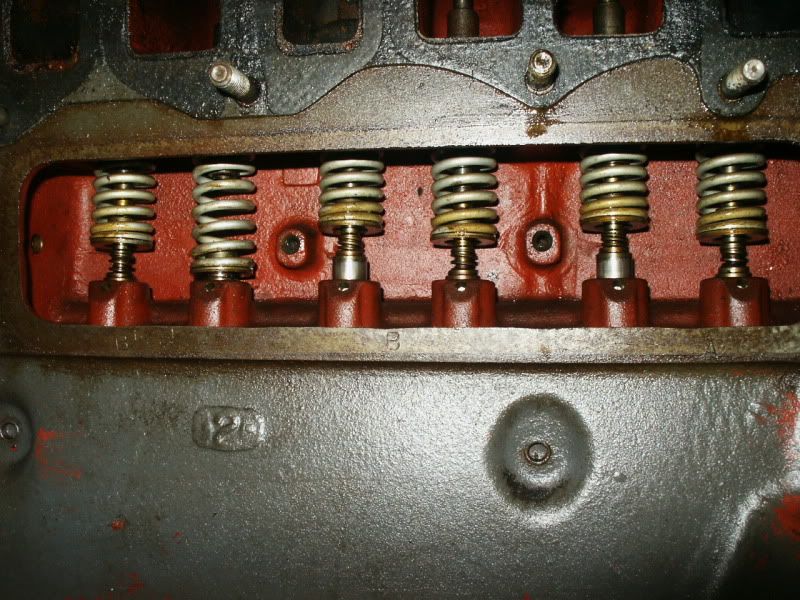

Well,I was wrong.It does have solid lifters...

BUT,this headers going to have to come off to get to the rear ones.

Cylinders #1 and 2 are checking at .011 int and .015 exh so I will

be loosening up to the .014 int and .017 exh that Walt recommends.

This may not fix the leaking intakes on #5 and 6 but at least I'll

know what I have.The covers were leaking anyhow.

0

0 -

You may already know this, but to be sure, remember to recheck the ex/in manifold studs/nuts to be sure after the engine has had time to heat up, that they are still tight. When I reset my lifters and replace my manifold gasket, mine were still not tight enough when the engine/exhaust manifold had cooled enough to get my hands back in there to retighten said nuts. Good luck, if you pass thru North Alabama, we're in the north west corner, can help. Bob0

-

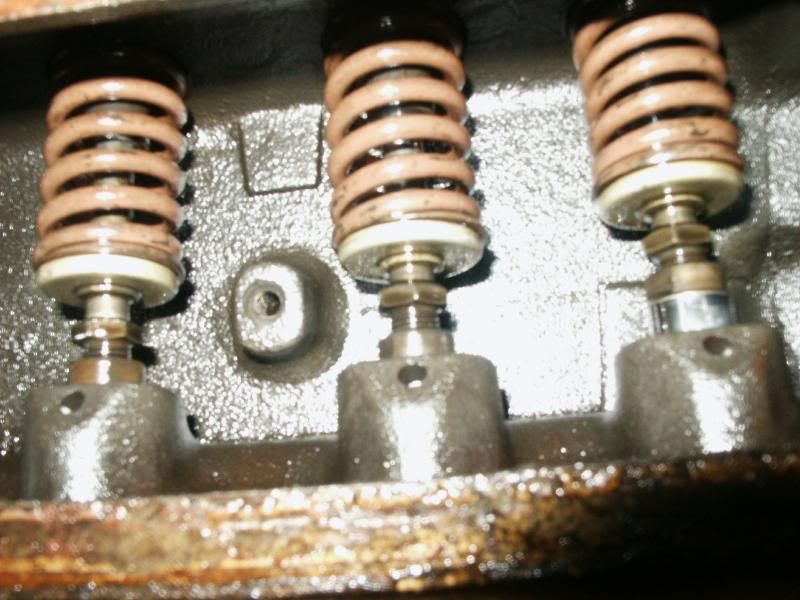

The offending intake valves are badly pitted on the face and the seats are pretty

rough too. Thinking I'd just grab a couple valves out of my other rebuilt 55 engine

and walla! hydraulic lifters in that one. Here's the weird part,valve head dia. of

the intake I pulled out of the running motor is 1.775" and the one out of the spare

motor is 1.830 dia. Also the valve from the hydraulic lifter spare motor is about

.100" longer with the difference being from the valve lock groove to the tip...

Hopefully I will something resolved tomorrow. Time is running out. 0

0 -

Well it appears that your "spare" engine is actually a '56 application. The different valve diameter is interesting, I'll have to check my original intake valves (if I still have any) and what the diameter is. The extra length of the '56 valve is probably to allow for machining in order to set up the preload.

Update: the intake valve from the '56 is correct, the smaller diameter from the '55 can only be the result of some grinding/machining, maybe to reseat the valve. All the "big block" sixes had a 1.831 intake valve.0 -

Yes,in addition to having the diameter turned down some,they also

had up to .100 ground of the tips.No idea what the reasoning was there...

UPDATE:I did manage to get on the road on time.Took all the exh valves from #4,5,6 and three intake valves from the"spare" engine

to the machine shop and had them refaced.He also loaded up various

pilots,stones,etc and made a housecall to grind the seats on those

3 cylinders. Reassembly went well with the majority of time spent

cleaning decks,valves,cylinders,etc. Valves were set to .014" and

.017" cold and the engine fired immediately and ran beautifully

while I resynched the carbs and idle adjustments.

Loaded up and headed for TN for my first leg.It ran better than

it ever has and I was well into GA before I noticed some smoke trailing me. I pulled off and she was a bit rough again.A quick look

underneath revealed smoke puffing from the road draft tube and pulling the breather off the oil fill tube confirmed I had hurt it.

Pulling plug wires one at a time while running said #5 was again the

problem and that the piston or rings had been compromised.Leaving the

plug wire off of #5 alleviated most of the pressure and almost all the smoke from the crankcase so I made a run for my first stop in TN

on 5 cylinders (still more cubes than Chevys stovebolt). Nearly to

the south side of Atlanta when it shut off at speed. Roadside diagnosis revealed no spark although power was present to the coil.

While cranking it with the coil wire out of the distributor it still

had a very hot spark to surrounding grounds including my hand...Couldn't get it to jump to the distributor tho.Nothing I could

see to be a problem with cap or rotor so broke out the AAA card and

made the call. While the rollback wrecker got me thru Atlanta my buddy headed south from TN with a trailer,we met up and made the swap

and dropped the Hudson at his home before we continued to Vegas.

Another buddies wedding was here yesterday so I borrowed a 49 Dodge

Wayfarer to stand in for the Hudson during the ceremony.

Forensic study of what failed and why will have to wait till I get

back home this week and retrieve the Hudson from TN.

Stay tuned for my next chapter. LOL0 -

Finally got her trailered back home yesterday.Cap and rotor and she fired right up...Running

with the plug wire off #5 must have carbon tracked the cap. Anyway still hard puff

and smoke from the crankcase. Compression on #5 at 40 psi and leakdown at 15/80.

Sure would be nice if just a stuck ring but with that much leakage I'll bet the piston is hurt worse. Either way it has to come out now and I'll share the carnage

once its torn down.0 -

If you ever run the engine with a plug wire off you are likely to get breakdown of the coil or condensor, or tracking in the distributor cap, due to the high voltage build-up. If you ever have to do it again, ensure the plug lead is grounded.0

-

Great advice for sure.When I pulled the wire from the bad cylinder I popped it on

a stud/nut near the coil.At some time afterward it popped back off,I had gone approx.

100 miles when it failed with no warning(just like turning the key off).My ignition

is a somewhat older version of the Crane Cams breakerless conversions that has been

absolutely trouble free in the 5-6 years I've had it and longer I'm sure for the PO.

Try as I might to wipe off a carbon track that I couldn't even see, the battery and

I gave up after about an hour and I made the call to the auto club and curled up in

the back seat for a little shut-eye till they got there.0 -

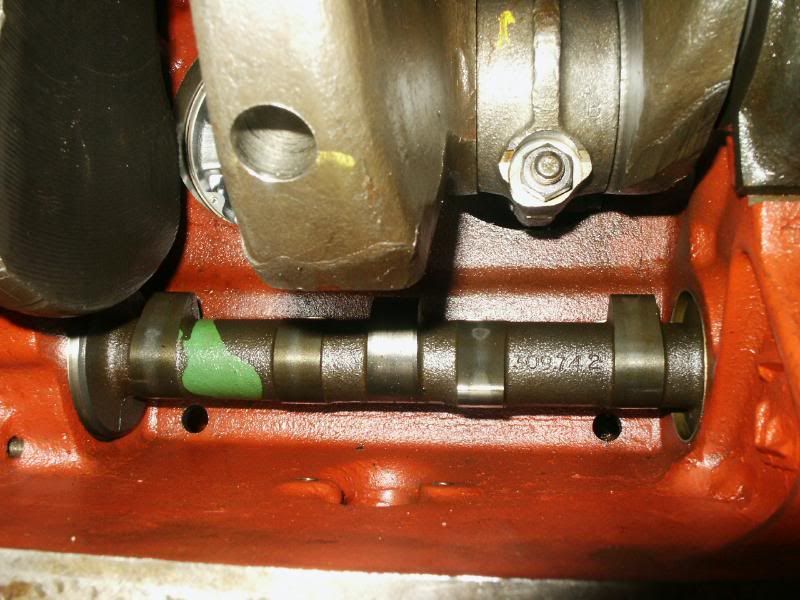

Great news! NO major damage,just broken compression rings on #5.

Oil pump drive gear looks better than I expected.This engine has been previously

rebuilt.

Looks like this camshaft has been reground before. Not much base circle left here.

Aftermarket Jahns Piston,both compression rings broke and the wrist pins a little

looser than what I like.

I'll be completing the teardown and see where I go from here.0 -

TwinH The carbs look like new are they? If not who did the clean-up on them. Thanks Rudy0

-

super651 wrote:TwinH The carbs look like new are they? If not who did the clean-up on them. Thanks Rudy

Rudy,yes the carbs are new or "renewed" I should say,by:

Daytona Parts Co.

and what an awesome job they do.0 -

A very good friend of mine, no longer with us, once told me that in taking a trip with an old car, half the fun was the trip. The other half was getting it out of the garage!!!!!!! Smart man was TK.

Hudsonly,

Alex Burr

Memphis, TN0 -

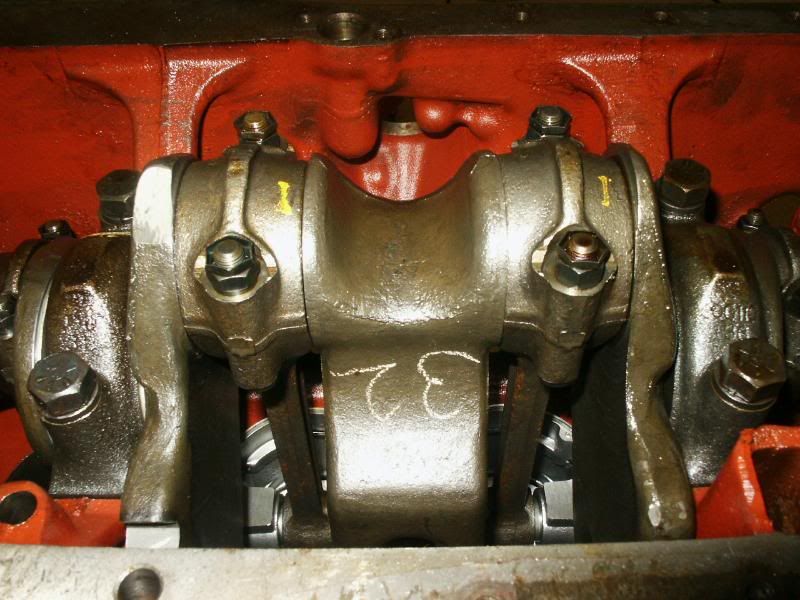

Back again....Plan B. Ring lands are hopelessly worn on the old Jahns Pistons,block

.060 over and the crank turned 30/30 SO,if I'm going to rebuild a motor I want to use

the best parts I've got. Back to the spare motor that came with the car now collecting

dust under some shelving.Its another 55 block/crank but for some reason had hydraulic lifters. Now tearing down this motor is another head scratcher. New pistons in a standard bore and new bearings on a crank that hasn't been run either.The valvetrain

on the other hand seems to be all used stuff.The 309742 cam is visibly a different

profile than the reground 309742 from the other motor. Valves are reground with little

margin left but the guides are all new.Also the inside of the crankcase is coated with

glyptal seemingly before any machining was done.Dropped these parts off at my local

machine shop yesterday to check the bores,clearances,etc.and run a profile on the cam

to compare to the other one.If this all works out I'll be saving considerable $$ getting the Hornadore back on the road.

Looks like somebodies been doing some balancing too.

Rubber ink stamped #'s on the rod caps, 0's,1's and 2's

0

0 -

OK,life gets in the way,finally back on the 308 build. Just to bring you back up to speed the motor I pulled out of our 49 was already .060" oversize Jahns pistons and

.030"/.030" on the crank with the pistons being slap wore-out.Plan 'B' is the spare

308 that came with the car and finding it to be a fresh build that never was run,but had suffered some poor storage over the years. New standard(pinned)pistons and new never run standard crank. The dilemma faced now is my machinist balking at the 'tight'

main bearing clearances(by his standards). My take and factory specs of .0005"-.0015"

is that these babbit backed steel shell bearings are much softer than the Clevite and tri-metal bearings he is used to dealing with. Clearances on the mains are as follows:

#1-.0013" #2-.0013 #3-.0014" #4-.0017 and .0055"endplay. Bearing part#'s jive with

standard #'s in the manual except for the #3 thrust bearing.

#1-300260 #2-300261 #3-302574 #4-300263.

The machinist would like to hone the main bearing bores to loosen the clearances.

I am leaning heavily toward telling him to leave as is,but would value advice here.

Its no 'race' motor,just a little hotter with a super 7x cam,7x valves,Clifford head

and headers. BTW, rod bearing clearances are: #1-.0021" #2-.0025" #3-.0025"

#4-.0022" #5-.0019" #6-.0018" and I can live with these, I believe.0 -

Man, how can an engine this purdy have any problems?...slim0

-

Nothing wrong with those JAHNS PISTONS. I have 60 over in my engine and so far has been driven 130,000 miles and still going strong and only uses 1 quart of oil in 3,000 miles. This car is driven at speeds over 90 per and across this country 11 times so far. Build a good stock engine and enjoy the ride. Walt Mordenti0

This discussion has been closed.

Categories

- 37K All Categories

- 115 Hudson 1916 - 1929

- 21 Upcoming Events

- 94 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 180 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 77 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos