A few more 308 questions please

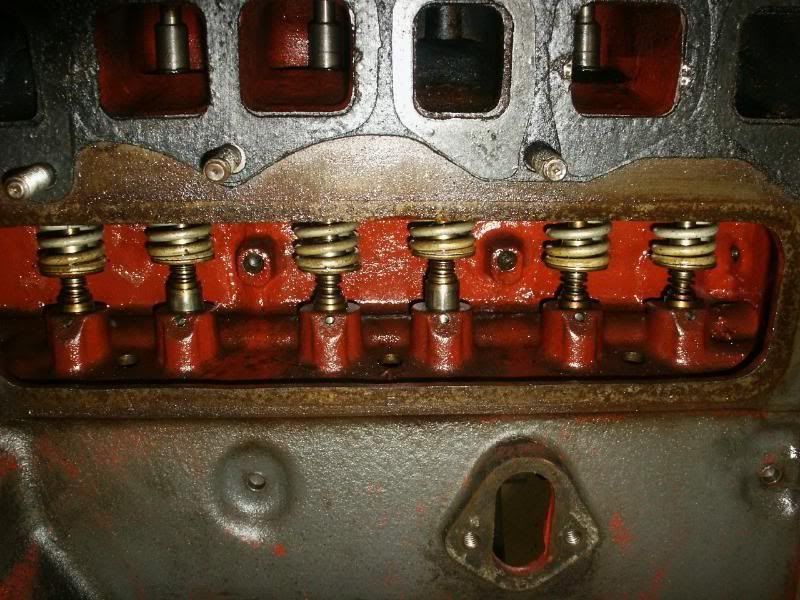

In reading an old post from Jan 2011 about 308 block identification, I am making an assumption about my 53 Hornet 308 block. I have a casting number under my dist that is L95 and under that is a #5325000 and CWC under that. From reading the old post I think these numbers transulate into- date= Dec 9 1955 and the block number 5325000 means it is probably a 55 block. The dipstick is at the front edge of the starter. Can anyone correct me if I'm wrong. Check my pic please.

I measured the thickness of the head and found it to be screwed up I think. The end towards the firewall is 1.942 on both driver side and pass side. The front end near the thermostat housing is 1.928 on both pass and driver sides. I am confused how this could happen. I think the most you can take off of a 2'' head is .060 which would leave 1.940. I'm in trouble, right !! Need a new head ?? Thanks in advance. Richie.

I measured the thickness of the head and found it to be screwed up I think. The end towards the firewall is 1.942 on both driver side and pass side. The front end near the thermostat housing is 1.928 on both pass and driver sides. I am confused how this could happen. I think the most you can take off of a 2'' head is .060 which would leave 1.940. I'm in trouble, right !! Need a new head ?? Thanks in advance. Richie.

0

Comments

-

The differance from front to back sounds like a poor job of machine work is all. Probably not a big deal in itself if the face is flat from front to back / left to right. Can be checked by a machineist straight edge. However it does sound like its past the stated limits they like to stay within,

Roger0 -

one of Smokey Yunick's cheating "coup de gras" was to mill the block; it was easy & quick for inspectors to "mike" the thickness of a head to see if it had been milled but not the block itself, LOL!!!

"where there's a will, there's a way"!0 -

Hi Roger, I will have the shop check it but don't think I can have it milled any further so I hope it is flat.

Oldhudsons, I heard some good stories about Smokey also. He would remove the ring gear from a flywheel and drill deep holes all the way around it to lighten it and re install the ring gear. He was a sharp guy. Richie.0 -

The compression ratio (cylinder volume) will be different from front to rear. Will it make enought difference to notice ? I haven't a clue.0

-

SuperDave, I think you are right and I have no idea what affect it will have. I can't believe a machine shop could do this kind of work. I'll probably have to buy a new head.Richie.0

-

Cinsidering how easy it should be to find a good head for that it may not be worth the trouble messing with the old one,

Roger0 -

I have seen quite a few heads that were different "thicknesses" from end-to*end. The "machine" shops in our small town didn't use a milling machine, but had a "surfacing" table. Large steel table w/ a circular stone to surface the heads.

It was pretty easy to surface a cylinder head to different thicknesses at the ends. A little extra pressure and the head was surfaced different at each end.0 -

Like I said above my big concern would be how flat it was ,

Roger0 -

Bigboy308, this car came from CA, I have no idea about the shops out there or their quality. I have used the local shop near by and had excellent results. Richie.0

-

Roger, do you have a good head you want to part with ?? Richie.0

-

Thanks Ken, I'll be taking the engine apart next week. Richie.0

-

I dont think so right now ,I will look though.

Roger0 -

Richie, I might have one. I'll check and let you know.

Matt0 -

Thanks guys. Richie.0

-

Ken U-Tx, Do the hydraulic lifters still have adjusting nuts like to solid lifters? The lifters in my L95 casting number block have adjusting nuts. Thanks, Richie.0

-

Hydraulics.

0

0 -

Thanks TwinH, my lifters definately don't look like those. Can you put solid lifters on a hydraulic cam ?? Or someone had to change the cam to a solid lifter cam ? Thanks, Richie.0

-

1955 Hash's had solid lifters and (presumably) the old standard cam (344). '56 had hydraulic lifters and a "redesigned" and "long dwell" version of the '54 flat top., 260 deg duration, .366 lift. I would not use stock solids on this cam. Remove the cam and verify the casting number. There appears to have been several cams utilized by the 308, I've seen reference to about six or so casting numbers. At one time there was an attempt on this site to catalog all the numbers and characteristics.0

-

Dougson, I should have the engine out later this week and will post the cam number here. My parts book only goes to 1954 but I'll check that first thing. Thanks, Richie.0

-

Ken, I have solid lifters and the car ran really good for about a week so I would think the cam is a solid lifter cam. I'll see what happens when I get it apart. It's 26 degrees this morning and no heat in the garage so I'll wait a day or so before working on it. Thanks. Richie.0

-

My '56 cam is a "309742" casting, introduced in '54 as the "Flat top 7X", but read '56 factory promotion material, these cams were "redesigned" as the "long dwell" hydraulic cam. I believe that all '56 Hornets used this cam. The '56 308 had the highest HP rating (175) of any production 308.0

-

Roger, Matt, any luck with finding a head for my 308 ? Thanks. Richie.0

-

Richie the best bet I have looks like an alluminium 308 head that shows 20 tho removed. So it has room to be cleaned up if needed ,and probably should be .There is another one with 15 tho removed #300006 part number but its not in the book. I think its a 308 head - not positive. Neither one shows much water jacket damage inside . These are on the shelf ,I may have an iron one on a motor some place in the warehouse,

Roger

0 -

Roger, I want to stay with an iron head, no hurry as it will be a month or so before I'll need it. Thanks Roger. Richie.0

-

I may have a 262 head that would fit. Give higher compresion though.

Roger0 -

Roger, would it need to be re-surfaced and if so would it create blown head gasket problems? Has it been re-surfaced already? I only want to do this one time, if you think it will work OK that's fine with me. I want to be like Walt and drive across country and not worry about anything. I know my way around the muscle cars of the sixties pretty good but I'm learning as I go about the 308 flathead. Thanks Roger. Richie.0

-

Any I have would need to be checked because I dont have proper equipment to declare one straight. I can measure it for how many times its been milled. Those that I listed above were 15 & 20 thousand's less than the 2" factory new measurement. You can go to at least 60. Although it my looking thru the pile I found one that had 75 off. I will say however that was a 262 head I took off a 1954 ,308 motor with a blown gasket.

I would think if you were going to use any old head it at least needs to be checked with a machinist straight edge. If it were me I would have just a little taken off to get a nice clean face.

I can understand how the Hudson is different than what you may have been used to. They didnt realy pay attention to how everyone else did things. They had thier own way to get it done ,put a lot of engineering into the cars. The Stepdown cars look massive just like thier cometitors at the time. Yet weighed much less and were stronger and quieter.0 -

Roger, I will have whatever head I get surfaced. I would like to have a 308 head and surface it, that way I wouldn't have too much compression, as a 262 head might be too much compression after surfacing it. I appreciate your time checking the heads Roger. Thanks. Richie.0

-

I agree ,used to be more compession was better but with todays crapgas I dont know anymore,

Roger0 -

Richie-

I'm probably not the one to comment, but I don't believe you can get "too much compression" from a flathead. If you have a higher compression, and your engine pings, you just have to have a higher octane to eliminate the ping, i.e., better quality combustibles. I am currently having a hopped up 308 built which is utilizing a milled 262 head and the 7x grinding. Honestly, with a flathead, I don't believe you could get the compression up high enough to do damage like blow head gaskets, which would be more operator error in the intstallation than in the high compression. It's not like you are going to be up in the 12:1 range, no matter what you do. Like I said, I'm not the one to really comment, but without some serious modification, I'm not even sure you could much above the 9 or 9.5:1 range on a 308.

Would like to hear someone like Ken-U-Tex's comments on the matter.0

This discussion has been closed.

Categories

- 37K All Categories

- 113 Hudson 1916 - 1929

- 21 Upcoming Events

- 94 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 180 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 608 Vehicles

- 2.2K Parts & Pieces

- 77 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos