OIL PRESSURE RELIEF VALVE SPRING

If someone has a NOS or good, used OIL PRESSURE RELIEF VALVE SPRING (308) handy for taking dimensions from, please give me:

1. the ~ LENGTH of the factory or NOS spring (uncompressed, of course)

2. the ~ OUTSIDE DIAMETER of the spring

Note: I have plumbed a pressure gauge from the port just above the oil pressure relief valve location.

At IDLE the pressure is ~ 44 psi (I've been told it should be ~ 20 psi)

at 2000 rpms it's ~ 48 psi (been told it need not exceed ~ 40 psi)

I'm trying to figure out why the oil pressure is seemingly too high.

I'm concerned that it might destroy the oil pump gear. Any ideas?

1. the ~ LENGTH of the factory or NOS spring (uncompressed, of course)

2. the ~ OUTSIDE DIAMETER of the spring

Note: I have plumbed a pressure gauge from the port just above the oil pressure relief valve location.

At IDLE the pressure is ~ 44 psi (I've been told it should be ~ 20 psi)

at 2000 rpms it's ~ 48 psi (been told it need not exceed ~ 40 psi)

I'm trying to figure out why the oil pressure is seemingly too high.

I'm concerned that it might destroy the oil pump gear. Any ideas?

0

Comments

-

This is some info I recd via e-mail;

QUOTing:

When engine is warm it should idle at 20 pounds and over 35 miles per hour it should stay at 38 to 40 pounds. If pressure is higher you can wipe out the rod bearings. Someone had to play with the pressure regulator spring. It's on the left side of the engine just behind the distributor, and you need a 1 1/8 inch socket to remove the cap, be careful the spring doesn't fly out and check if someone installed washers inside the cap to add pressure to the spring. Also make sure that the plunger is free in the block. If no washers then someone added a stronger relief spring.

closed QUOTE

No washers were added, plus the plunger moves freely. A loss of rod bearings is much worse than an oil pump gear. This must be resolved before it's run another mile.0 -

Your oil pressure guage is plumbed into the wrong place. The proper galley reading is to be read at the same place the original sender light is located. The hole going into the block just below and between your valve covers, directly above the oil pump.

You CANNOT get an accurate oil pressure reading from any of the ports that the original oil filter is plumbed into. The one you have your guage in, according to your post, is the one that guages the by-pass pressure.

I advised you once before to call the builder of your engine and get the lowdown on your oiling system modifications. I really don't think you are dealing with a "stock" Hudson oiling system.

Mark0 -

Mark, based upon your rationale, why is the oil pressure on the relief side of the engine (port just above the relieve valve) lower or higher (DIFFERENT) from the location that you recommend measuring pressure at?

I see no obvious rationale, involving higher-level thermodynamics, explaining why it would be so much higher, nor do I see why it varies but by 4 psi v. recommended 20 psi (20 - 38-40).

The quote-email I provided above is by an engine builder; do I need to repeat that to you??? A HUDSON engine builder, in case that is a +. I advise to you that you need to read it and reread it. I informed the engine builder prior to his response where I am measuring the pressure and that was of no concern to him-why you? In that short of a distance there should not be a measurable pressure drop, nor increase from the pump via the oil-flow route to the pressure relief location port where I am measuring the pressure, IMHO.0 -

Because John, the port you have your guage located in isn't subject to the same restriction the oil galley is, ie - the bearing clearances. The more restriction you have against the system, the more potential is preserved in the system. The less restriction, the less potential is contained (thats why worn out crank/cam bearings cause low oil pressures). The port you have your guage in is on the BACKSIDE of the by-pass piston and discharges into the oil pan, so it should be significantly less than the galley pressure due to the loss of potential - the lesser restriction. The only resistance to this flow of oil once it overcomes the spring is the clearance between the by-pass piston and the bore it sits in. Again, the tighter this fit, the higher pressure you will read at that port - but it DOES NOT indicate true galley pressure as its being delivered to the cam, main, and rod bearings. This has little to do with thermodynamics, its a hydraulic problem.

Unless Steve plugged the outlet into the oil pan, or placed a restrictive orifice in the passage back to the oil pan, it should in no way read the same pressure. I suspect your by-pass passages have been modified, or you have an extraordinarily good clearance between your by-pass piston and its bore.

A restriction in the return passage to the oil pan is highly likely as a method of flattening out your oil systems fluctuations due to the actuation of the by pass spring. If he did do that, he did you an enormous favor by eliminating the localized flow loss from the adjacent main bearing. When the by-pass spring allows the piston to open, it momentarily becomes the path of least resistance which decreases the amount of oil going through the main bearing 3rd from the front, consequently it reduces the flow to the 4th and 5th rod bearing compared to the rest of the engine.

Higher mathmatics in consideration, I really don't think you understand the system you are working with. I think you understand the drawings in your Hudson Service manual, but I don't believe that is the exact case with your engine. Its a Steve Farkaly 7x special, and he's the only one who knows what has been changed about your oiling system.

If you want to whip out the higher mathmatics, I'm game. In fact, I encourage it. I'm currently want to review my own oiling system's capacity and am taking measurements to apply a Bernoulli analysis of its adequacy. The Reynold's coefficients on the port passages are going to be impossible to get to any degree of accuracy, but the passage diameters are really what I'm after. Also, the amount of hp required to turn the pump in a range of pressures given the viscosity of the oil I intend to use.

All the science in the world isn't going to change the basic mechanical fact, that you are measuring oil pressure in the wrong place - get over it.

Mark Hudson0 -

“bernoulli's law - definition

Definition: A statement of the conservation of energy in a form useful for solving problems involving fluids. For a NON-viscous, incompressible fluid in steady flow, the sum of pressure, potential and kinetic energies per unit volume is constant at any point.

p + qv2/2 + qgy = constant

where p is the pressure, q is the density, v the velocity and y the height in a gravitational field of strength g, all measured at the same point. This quantity is then constant throughout the fluid.

Bernoulli's principle is used for, but not essential to, lift by airplanes0 -

"The port you have your guage in is on the BACKSIDE of the by-pass piston and discharges into the oil pan, so it should be significantly LESS than the galley pressure due to the loss of potential - the lesser restriction."

If what you say is correct, AND the idle pressure downstream of the relief valve is 44 psi, then the galley pressure must be HIGHER than 44 psi - I'm REALLY getting worried now! You are scaring me to death. Please stop quickly!

Oh, and when will you be teaching your next Thermodynamics course? I, for one, want to take it so please keep me posted. Thanks, Mark.0 -

Mark, if you are looking at the drvr's side of the engine directly at the oil pressure relief valve,

1. which direction (12 or 3 or 6 or 9 o'clock) is the oil flowing into the relief valve?

2. which direction (12, 3, 6, 9) is the oil flowing out of the relief valve?0 -

Just rec'd this quote below; some new, good info. I did earlier today put another gauge on the port above the oil pump (actually at the spinoff oil filter a few inches away) and it measured about 52 psi (idle and cold). ALSO, I realized that I do have 15-40 oil in it, so I will change to 10W-30 tomorrow as it's not fully broken in, and recheck it afterwards and try to dial it in the correct pressure. Next problem to stop the leaks.

QUOTE

You are measuring the oil return outlet, this is the oil that the check valve bypasses and sends to the original-style filter. Your pressure test has to be done on the oil sending switch pipe between the valve covers. Remove the switch and hook up an oil gauge. Then start your engine cold, check pressure at 1500 RPM's, Should read 50 lbs, then let it come up to full temp and check again at 1500 RPM's and should read 38-40 lbs. If readings are 10 or more lbs higher replace that spring. The oil filter must connect to the port above the relief valve, drivers side, and return to the port that is below the relief valve. ..... Hudson made 5 oil springs, color coded to adjust pressure. They were all the same length but different thickness spring material.

CLOSED QUOTE

Thanks for your help; this ole goat is never too old to learn0 -

Its all cool John, glad you got a second opinion that you could latch on to.

Benoulli's can be used for viscous fluids, and its applied to them all the time. The perfect model is for non viscous fluids - which if you think about it real hard, becomes an oxymoron.

I'm not that savvy on thermodynamics, I just know the basics. I'm more versed in Psychometrics, but not up to lecturing speed.

The oil entering the by-pass comes in at 9 o'clock from the crank snout. Its source is the number 3 main galley. It exits at 6 o'clock, which the lower plug of the original type oil filter (exit) is a port into the discharge from behind the piston/spring. Hitch a pressure guage into that port and you'll have an instant heart attack. The port you have your guage hooked up in is the supply side of the original oil filter and is ported into the body of the piston, but behind the piston face/relief port. This is why you get a pressure reading but it fluctuates wildly from near galley pressure to almost nothing in a stock engine. The clearance between the barrel of the relief piston and its bore really determines the max pressure you can read from this port. The big nut that holds the spring/piston in, is at 3 o'clock.

I really believe that you have a restriction in the exit port back to the oil pan. The way to check this would be to put a guage in the lower port, below the big relief retaining nut (the return line from an original type oil filter). If you have constant pressure here, your relief is blocked at the oil pan rail and is the source of all your excess pressure.

Its all cool, I know you are an intelligent man - I've been mulling the whole oiling system over as of late and have spent alot of time with it recently. I did it so I could get a better understanding of what I read in the Service Manual myself. That is why all this stuff is fresh on my mind, and pretty confident I knew what I was talking about.

Believe me, I listen to the likes of Geoff Clark and Billy Kemp. Randy Maas sets me back on my heels, as well as whole host of folks that have been working with this stuff longer than I've been alive. I'm doing my best to catch up.

For the record, I adjusted the pressure of my stock 308 by the same methods and pressures the sage advisors advocate. And, I've had a guage in all the places mentioned before, so I've seen the results. My guage is T'd into the same location as the idiot light sender.

Mark Hudson0 -

Hey I'm all ears here and learning as I go. Great thread!

Here's my dilemma, my 49 commodore came to me from an estate so I only have the

notes from the PO to go from. Thank god he documented most all the little changes

that he made,especially the wiring.

Its powered by a later model 308 and has been modified with a full flow oil filter.

Pulls oil off the pump itself and sends it to a spin on filter(ford type with bypass

built into the filter) then back to the engine via the galley hole between the valve

covers. As I got it the driver side has idiot lite switch,electric sending unit(for oil

pressure gauge mounted inside),and a mechanical gauge. The mechanical gauge

had a weird fluxuation to it so I swapped the old 60*sweep gauge for a new 270*

sweep guage and all that did was make the fluxuation much more noticable on the

gauge.

I just went out and rechecked it and here's how it went. Starts up on maybe 1st

step of high idle( nice warm-up rpm nothing excessive). Gauge on the block reads

approx. 44 psi. but slowly moves back and forth from about 42-48 psi. all the time

engine is rock steady. About 5 minutes in just like you'd flip a switch pressure dives

to 30 psi. I bring it down to curb idle and stays right at about 30 psi. fluxuation is

less pronounced(maybe 2-3 psi.) but when I rev it up,not on the first blip but by the

third blip on the throttle I can bounce the needle off the 60 psi. stop. By the way

oil is 15W40 Shell Rotella. Thinking that I'll change the gauge location first and go

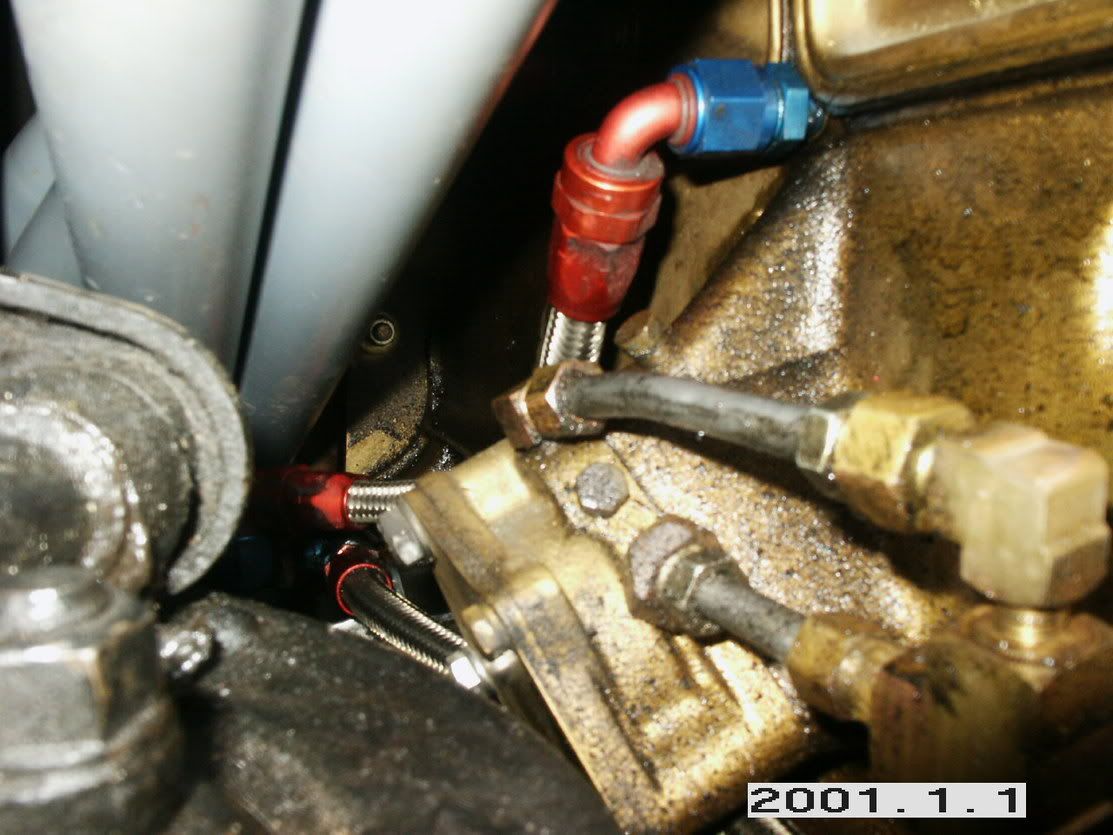

from there. Posting some pics to give you an idea,any comments are welcomed.

Drivers side. 0

0 -

rec'd this email last night:

QUOTE:

If engine is new you must use 10-30 for the first 10,000 miles then go to 10-40 from then on.

CLOSED QUOTE:

I removed the Rotella-T (15-40) from my engine last night. I'm changing the oil filter and putting in Valvoline 10W-30 this am. Will see how it responds later today.

TwinH, I too have a very similar remote oil filtering setup, returning to the oil galley in the same location as yours.

This is a generalized overall thermodynamics problem involving changes in temperature and pressure of fluids, whereupon the temperature and pressure are inversely proportional to each other.

As far as the erratic fluctuations in pressure, I suggest an oil/filter change to 10W-30 and see if the problem is any different. If so, how? It may be that you'll need to disassemble the oil pump to see if anything is outside of factory specs. You might check the oil pump gear too. Your problem almost seems more of a mechanical nature to me.

Keep us posted and I will too.

Thanks0 -

Twin-H, that is a very FINE looking powerplant you have there! Is that a Clifford head I see resting beneath those shiny air cleaners? Beautiful.

Your oil pump seems quite busy. The steel lines coming from your oil pump forward, do those by chance go to an oil cooler? I'm going to assume the AN fittings go to the remote oil filter.

With these remote filters, you still need to be aware of pressure differences associated with which side your guage is on. If you have your guage fitted in the supply side of the filter coming from the oil pump, your pressure is going to be higher than that of the actual oil galley due to the resistance of the filter element. If the guage is located between the filter exit and the oil galley (In Twin-H's picture, that would be the braided line with the red fitting going into the block between the valve covers) then you are reading the actual galley pressure being delivered to the mains and cam bearings.

From what I can tell of the pictures, the guage is located in the same by-pass port that has been discussed here in huge detail. The fluctuations of the guage will never ever go away, regardless of oil/filter, in this port. The range of pressures in the fluctuation sweep will change a bit, but the needle will still swing and get worse as the oil warms up and reaches its lowest viscosity.

Twin-H, looking at your driver's side - I can see the guage and sender switch in the port above the spring retaining nut for the by-pass. I think I also see another sender switch in the lower port, just below the by-pass. The upper position is actually not a bad place for the sender. If its calibrated to ground at 13 psi, that should be just fine for a new engine with a good fit between the by-pass piston and its bore. If an engine can't maintain 13 psi here at operating speeds, it would be a good early indicator that something is getting out of tolerance. On an older engine with some wear, be prepared to watch your idiot light dimly flicker at idle once it warms up. However, if you have a pressure guage at the right location - you'll know what the steady galley pressure is regardless of the dimly flickering idiot light.

Its been my experiance that going from 10/30 oil to 20/50, nets you about a 7 psi change in oil pressure as measured from the proper location in the circuitry. The thermodynamic application of a oil in a system is more a function of the ability to absorb and transfer heat, both from its own internal coefficient of friction and the work being imparted to it, as well as its ability to absorb and transfer heat from the other systems it comes in contact with. Oil does change characteristics as its temperature changes. These changes are what your oil's rating describes and its a measure of its viscosity at a certain temperature.

This next part is for John, because I'm trying to understand how this all hinges on thermodynamics alone. I'm looking to understand this perspective.

In a simply hydraulic system, the heat changes are due to friction the fluid encounters; its inherent friction due to shear, the friction imparted by its passing through a conduit, and the motive application of force in order to accomplish a given amount of work. Internal combustion engines also add heat generated by the combustion itself and the friction of its motion. What this heat does, and John noted, is change the viscosity of the lubricant.

The relationship viscosity has with a Bernoulli analysis is one of Friction. The more viscous the liquid is, the greater its internal friction is and is why its "thicker" to the feel. Viscosity is a determining factor in the Reynolds number, that ultimately determnes the frictional head. So viscosity does have a huge bearing on a Bernoulli based analysis of fluid mechanics. The variable that exists in the case of lubricants is the change in viscosity due to heat. So, thermodynamics certainly is an element as it relates to the lubricant, but only within the range of heats generated by the system itself and those imparted to the lubricant by its surroundings. As the viscosity lowers with heat, so does the frictional loss to the system. The work required to move the fluid lowers, and the pressure drops to reflect that change in viscosity - if all other variables in the system remain constant.

The way I understand the role of thermodynamics and the effectiveness of a lubricant is its ability to absorb heat and remain viscous enough to form a hydraulic layer between bearing surfaces. The amount of tolerance between bearing surfaces really determines the desirable viscosity range of the oil. You have to know the working heats associated with your engines conditions and match the viscosity at working temp to what is needed to maintain that hydraulic layer. Here is where manufacturer's guidelines are important - they figured that out already based upon empiracal trials. If your tolerances are closer than normal, you can get away with running a lower viscosity oil - the converse is true also.

This is why a newer engine is broken in with a lower viscosity lubricant. The tolerances are closer and the available clearance for a hydraulic layer is "thinner" between bearing surfaces. This allows a certain amount of "lapping" because surfaces are close enough to influence each other. As an engine wears and "laps" those few .0001" between surfaces, then a more viscous oil needs to be used to take up the slack in the allowable space needed to maintain the hydraulic layer between them.

I understand where thermodynamics come into play. But what I don't understand is that your oil pressures are outside the range of thermodynamic influence given the lubricants you are using? If you change the viscosity of the oil, you are going to change the pressure a small amount relative to the difference in what you want to run and what it is running. The solution then seems one of fluid mechanics rather than a general themodynamic problem. I do not understand how a change in viscosity or themodynamic property of your oil is going to drop your pressures 20 psi at idle, without lowering the viscosity to a point where you ultimately destroy your engine by compromising the ability to sustain a hydraulic layer. As I see it, you'll have a huge thermodynamic problem then - when your bearings begin to demonstrate properties of viscosity.

Mark Hudson0 -

Bravo I am really enjoying this thread. Keep up the high level of posts here.

Twin-H thats a nice looking engine I like the temp guage on the thermosat housing. How does that engine run and drive?0 -

The oil pressure on startup (cold/idle) at the oil galley above the pump is ~ 43 psi.

Hot it's ~30 psi (@ idle); a considerable improvement.

Hot & rev it up, goes over 50.

I was looking for an improvement & found it; great!

I'm considering straight 20, HD, but not too seriously.

Doesn't seem to be leaking as bad as before; seems to be some seepage around the distributor base; nothing some black RTV won't correct.

I'm preparing to build the original 262; I'll leave the oil pump original, and install a remote spin on/off oil filter on the drvr side, thus plumbing it to the two ports above & below the pressure relief valve. That'll work fine for me.

Once the 262 returns to its original home the 7X goes on ebay.

Thanks everyone.0 -

I have a question concerning the port above the bypass valve and the port (return) below the bypass.

Suppose both ports are plugged; does the oil have any way to return to the oil pan?

After viewing the Miller-Spring engine with a rubber hose connecting those 2 ports, it dawned on me that since I have the top port with a guage only (and no return to the lower port) , and my bottom port plugged, this may account for the extra high oil pressure.

UNLESS the bypass port allows for some portion of oil to return to the crankcase anyway.

Thanks for you feedback.

I think I had better do some replumbing soon to see what happens.0 -

Think I need two tylenol pills. My brain's a spinnen.

Randy0 -

I need 2 Marguerita's0

-

I'm like your idea better but a bit to fancy for me. Look guys--keep it simple. 1. You are not going to wear your bearings out at 50 lbs of pressure. Know what your main bearing and rod bearing clearances are relative to selecting the weight of oil you use. I doubt there is a tinkers dam worth of difference between the 5-30 & 10-30 when hot. After knowing what your clearances are and the side clearance is select your oil. I always run .003 on my mains &.002 on my rods running 20-50 valvoline in my race car. Yes, I run .025 side clearance. I want the oil in and out as fast as possible to cool. I look at the back of the bearings to determine how hot they are getting. With the extra side clearance, they will run cooler. The oil pump will flow plenty of volume.

Sorry, I don't know much about your laws.

Forrest Gump0 -

Umm... okay. From what I've gathered off this thread, Hudson motors need oil. Right?0

This discussion has been closed.

Categories

- 37K All Categories

- 113 Hudson 1916 - 1929

- 20 Upcoming Events

- 93 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 180 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 608 Vehicles

- 2.2K Parts & Pieces

- 77 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos