Would you like a Hudson Engine Hoist?

Comments

-

A few years ago I purchased the reproduction Kent-Moore oil pump gear alignment tool for a stepdown 6 cylinder engine made by Gert Kristiansen of Salt Lake City. I only used it once so far, but it sure came in handy to get the job done.

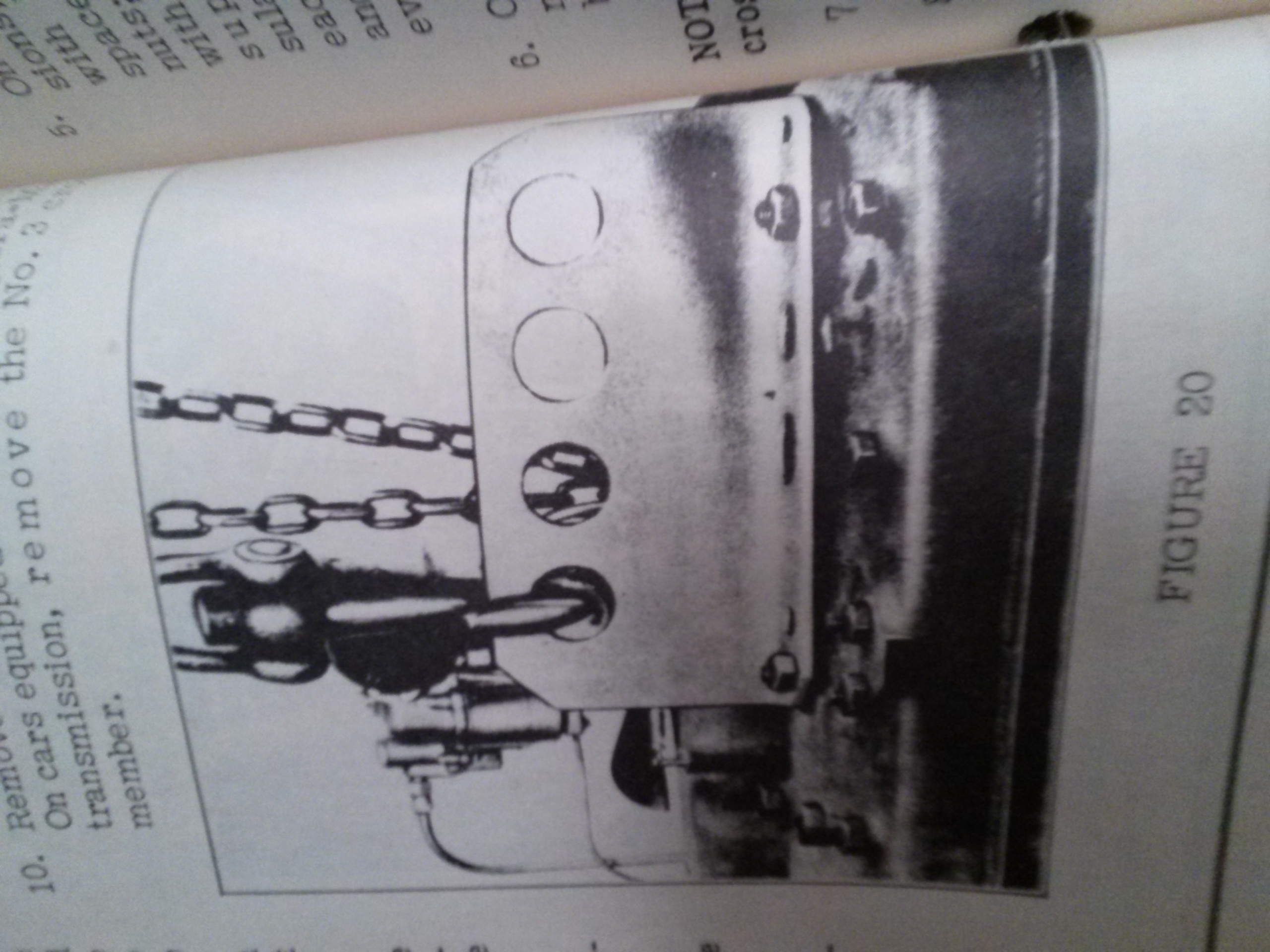

This looks like the same thing. You (or a mechanic working on your stepdown engine) may only use this engine hoist bracket once to lift the engine out or even raise it a bit to, say, replace the front engine mounts, but it'd be just the piece of equipment to have to help get the job done.

That said, I'll get the ball rollin', RL, and you can put me down to purchase one for $50.00.

While it's not in use for its intended purpose, you can perhaps use it as a heavy duty door stop or better yet place it on the coffee table in the living room to act as a modern piece of machine art. The little lady will love you for that!

Dan

0 -

Put me down for one as well.

Kdancy0 -

Thanks Russ,John Forkner will take one also.0

-

Hello Mr. Chilton,

I would like to be placed on your list for one of the Hudson engine hoists you are having made.

Thank you, and take care,

Steve Bryson

0 -

Russ,

Very nice looking work. I am interested in being added to the list. Don't know if I will need to use it but having the right tool is far better than adapting a poor tool.

Drew

0 -

Russell,Please put me on the list!Thanks, Michael0

-

Russell I am interested also. Thanks

Hudso.0 -

I sent all of the above a PM. If you did not get a PM from me, then I all ready have mailing addresses for you and are included on my ongoing list. With the emails I have received, we are nearly up to 20 units. I will probably get a run of 25 or 30 made sometime in the next 10 days or so. Will keep everyone posted. There is an ad going out in our local Chapter Newsletter, which gets shared with all of the other chapters and I'm sure will generate a little more interest.Thank you everyone who has contacted me and expressed a desire to own this unique tool!0

-

I will take one also.

Jay

0 -

Please add me to the list.0

-

I'd like one as well.

Kim Kramer0 -

This is still in the works, but the company doing the cut-outs are dragging their feet. Will keep everyone posted.0

-

Update?0

-

I would like one too if possible

0 -

Update ??

0 -

The shop I was working with decided they weren't making enough money and I am now (and have been) searching for another place that would be interested in taking on a small production run. I've checked with 3 other shops since the initial deal with no luck. Next time I'll make sure I make a post about it when I have ALL of the products in hand.0

-

Thanks for trying!0

-

Seems the shops you are trying have too much work to care about the little man, first mistake in business, find a small shop with less work and a more interested owner.0

-

I deal with this quite a bit. The small shops arent set up for a real production run and don't have the quality large shops tend to have , and the shops who can run production don't want to prototype. Fortunately I've been able to use companies I deal with on my day job that give me production quality at a fair price, more or less as a favor. CNC equipment is expensive per hour, and they want to keep it humming along.0

-

Doug Wildrick reproduced these a number of years ago. I bought one and have used it for everything from engine work to transmission removal. Perhaps Doug has the resource to have another run of these produced.

Allan

0 -

Check with McCombs Steel in Statesville, NC. A few years back when I was trying to produce a bracket for air conditioners for Hudsons, those guys were real cooperative in helping me design and produce the steel plate that was the greater part of the bracket.0

-

The one shop in my area that is able to make te bracket has only a plasma cutter. That leaves a rough edge on all the cuts. A water jet is needed to make smooth edges. I could use one that was plasma cut, but for production that may not be satisfactory.

0 -

The local shop I use for my brake kit's laser cuts the flat parts now, it leaves a very smooth edge. It rought than milling, but not much.0

-

What are the dimensions of the engine hoist shown in the photos above, including the thickness of the metal. I'm going to try to print a picture of it to show to the metal shop what it looks like in an attempt to get them to make me one.0

-

Jason, the price I got to make them up using plasma cutter was 27.50 each. That includes the metal, cutting then braking into shape. Send me your e-mail address and I'll forward the info to you.

0 -

Kdancy, I sent you a PM.0

-

I told the metal shop to go ahead and make 3 up. Let me see how they turn out. I post when I pick them up.

0 -

I told my metal shop guy to make only one. I will post pics of it when I get it back as well.0

-

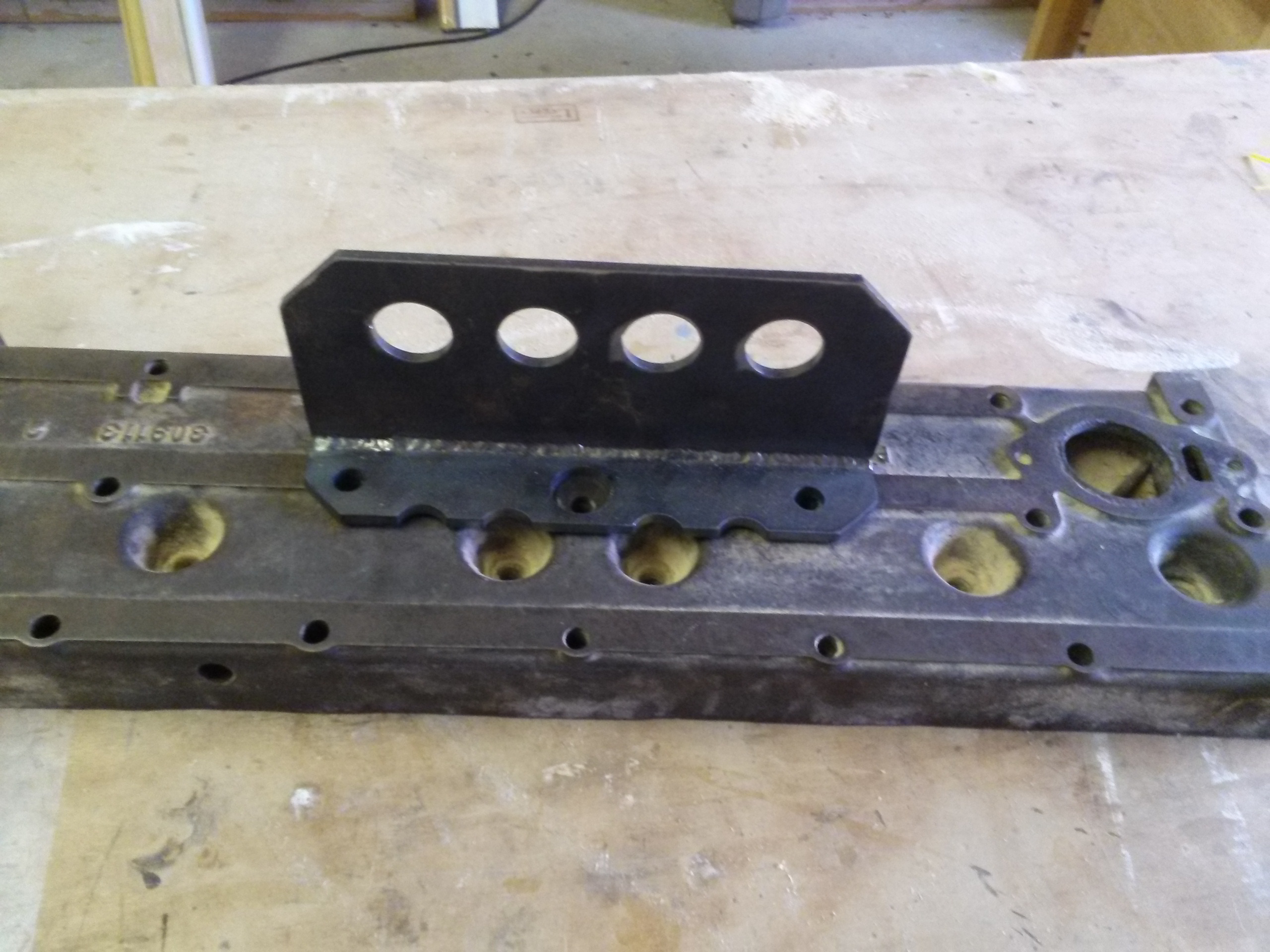

As promised, here are some pictures of the engine hoist that the metal shop made for me. The only thing that wasn't according to plans as far as I can see is that the plate is 3/8 instead of 1/4 inch thick, however that should be a plus.0

-

Jason that is a little different than the print. The print shows notches so you can place it over the spark plugs.

That should work just fine through.0

Categories

- 37K All Categories

- 117 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 610 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos