Distributor timing- Real world

I'm developing a timing curve for my 6.

I have been digging through the factory specs and analyzing timing curve.

To me the specs just seem to be counter productive to what most engine curves are.

So what I'm looking for is some "real world" timing setting that guys who drive their Hudson are using.

I realize that compression ratio plays an important factor in timing when it comes to ping so there are going to be some variations.

A little discussion and terminology first.

Types of timing.

Base timing- This is the physical setting of the distr in relation to the TDC-top dead center of piston #1. My manuals show Hudson set this at 0*. But state that you adjust this setting to achieve a slight ping from the engine while in high gear at 15mph and apply full throttle. So this gives us a wide range of base timing.

The next variable is the line of sight to that great timing mark back at the flywheel. If your tall and looking down or if you sight the timing mark directly inline will make a huge difference in the actual timing setting.

A distr has 2 methods of applying timing:

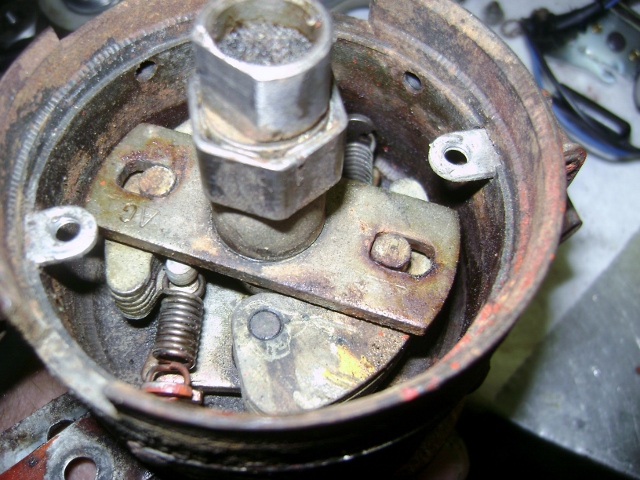

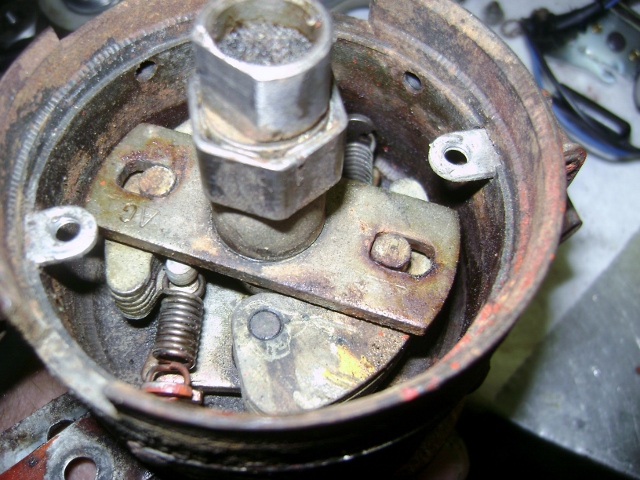

Mechanical advance- timing is applied dependent on RPM only. It uses weights that are thrown out due to the rotation force as the distr shaft turns. The rate they move out is controlled by springs. A lighter spring allows the timing to apply faster and a heavier spring slows it down. When you have the timing curve of your distributor custom tuned they adjust the spring tension rates and the length of the slot.

A slot in the advance plate or advance shaft control the total amount of mech adv.

The next method of applying advance is vacuum. This changes timing based on engine load.

There's also 2 methods of applying vacuum advance.

Ported- vacuum port is above the throttle plate and has no advance at a closed throttle but increases as the throttle is opened then drops off again as the throttle is opened all the way and the pressures above and below the throttle plate equalize.

Manifold vacuum- Port is below the throttle plate and applies max advance at idle and then decreases as the throttle is applied until the throttle is wide open and the pressures equalize.

At some point the ported and manifold vacuum curves will meet. The difference is the initial timing applied at idle.

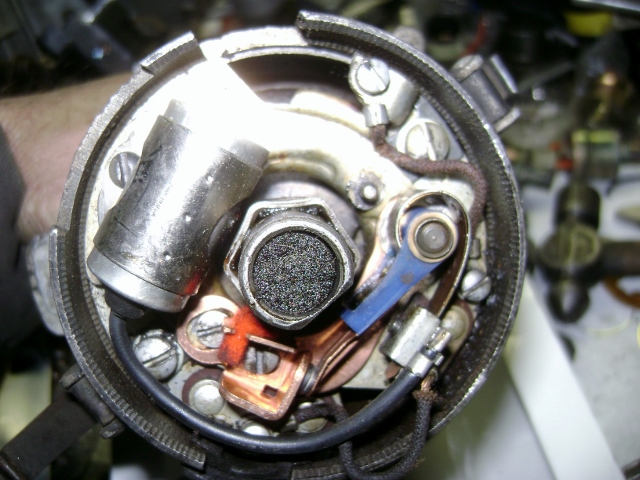

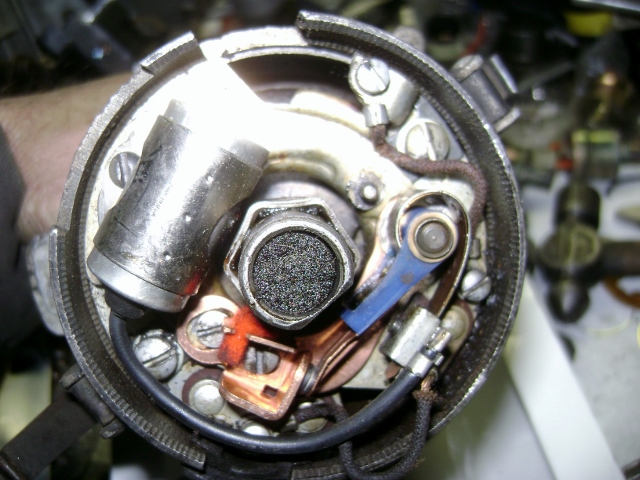

The vacuum advance is the little canister on the side of the distr. It connects to the base plate in the distr and physically rotates the plate in the opposite direction of distr rotation to advance the timing as vacuum is applied.

A spring in the canister controls how fast it is applied and a slot controls the amount applied.

There are many distributor variations used by Hudson over the years. The specs provided in the manual are distr specs which are 1/2 the actual engine specs due to the crank turning twice for each cam rotation which is what drives the distributor.

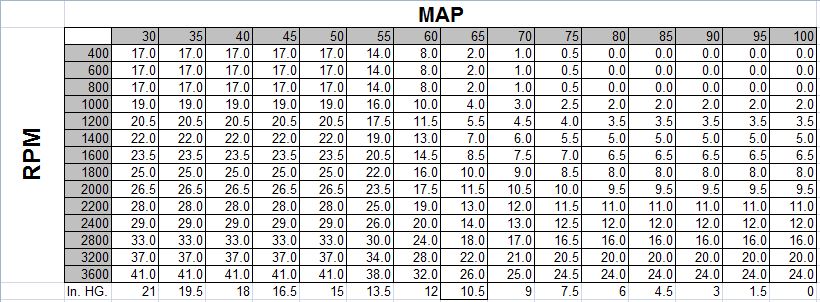

Here's one of the specs sheets from the manual. I also attached the service bulletin below that discusses some of the changes through the years.

Things to note in the specs

I'm going to use the 48-49 specs.

It shows the mechanical adv starts at 3* at 800rpm which means we start at 6* at 1600rpm when looking at the crank.

It's max advance is 12* at 2000rpm which gives us 24* at 4000 rpm.

To me this is really kind of a weak timing advance. What I have found is most older factory engines. like about 32* timing at full throttle.

Which would mean we could set the base timing at about 8* to get our optimum wide open timing.

The part that really kind of bugs me is the slow rate that Hudson applied the timing. Basically you have no timing advance at all until the engine hit 1600rpm.

Normally you like to bring the timing in faster at a lower rpm and the taper it slower as the rpm rises. This gives a little better drivability by getting the car out of the hole a little faster.

The vacuum advance is used to improve that around town drivability. It is only applied at part throttle applications so around town and light throttle on the highway. Once you put your foot down the vacuum adv is 0*

In the spec sheet we have 2* at 10.5"hg and 8.5* at 14"hg which gives us 4* and 17*

So if we are driving down the highway at 4000rpm we will have the 24* mech adv added to the 17* vac adv plus any base timing we set.

which if my math is correct we will have 41* timing and if we set the base timing at 8* will give us 49* max timing under light loads.

So now that we have discussed all the basic operations of the distr adv.......

What are you guys running for timing and has anyone retuned the curve in their distr?

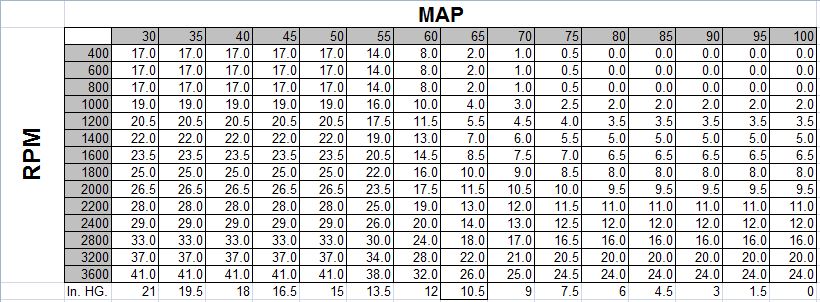

Here is a table representation of combined timing specs with no base timing added.

I have been digging through the factory specs and analyzing timing curve.

To me the specs just seem to be counter productive to what most engine curves are.

So what I'm looking for is some "real world" timing setting that guys who drive their Hudson are using.

I realize that compression ratio plays an important factor in timing when it comes to ping so there are going to be some variations.

A little discussion and terminology first.

Types of timing.

Base timing- This is the physical setting of the distr in relation to the TDC-top dead center of piston #1. My manuals show Hudson set this at 0*. But state that you adjust this setting to achieve a slight ping from the engine while in high gear at 15mph and apply full throttle. So this gives us a wide range of base timing.

The next variable is the line of sight to that great timing mark back at the flywheel. If your tall and looking down or if you sight the timing mark directly inline will make a huge difference in the actual timing setting.

A distr has 2 methods of applying timing:

Mechanical advance- timing is applied dependent on RPM only. It uses weights that are thrown out due to the rotation force as the distr shaft turns. The rate they move out is controlled by springs. A lighter spring allows the timing to apply faster and a heavier spring slows it down. When you have the timing curve of your distributor custom tuned they adjust the spring tension rates and the length of the slot.

A slot in the advance plate or advance shaft control the total amount of mech adv.

The next method of applying advance is vacuum. This changes timing based on engine load.

There's also 2 methods of applying vacuum advance.

Ported- vacuum port is above the throttle plate and has no advance at a closed throttle but increases as the throttle is opened then drops off again as the throttle is opened all the way and the pressures above and below the throttle plate equalize.

Manifold vacuum- Port is below the throttle plate and applies max advance at idle and then decreases as the throttle is applied until the throttle is wide open and the pressures equalize.

At some point the ported and manifold vacuum curves will meet. The difference is the initial timing applied at idle.

The vacuum advance is the little canister on the side of the distr. It connects to the base plate in the distr and physically rotates the plate in the opposite direction of distr rotation to advance the timing as vacuum is applied.

A spring in the canister controls how fast it is applied and a slot controls the amount applied.

There are many distributor variations used by Hudson over the years. The specs provided in the manual are distr specs which are 1/2 the actual engine specs due to the crank turning twice for each cam rotation which is what drives the distributor.

Here's one of the specs sheets from the manual. I also attached the service bulletin below that discusses some of the changes through the years.

Things to note in the specs

I'm going to use the 48-49 specs.

It shows the mechanical adv starts at 3* at 800rpm which means we start at 6* at 1600rpm when looking at the crank.

It's max advance is 12* at 2000rpm which gives us 24* at 4000 rpm.

To me this is really kind of a weak timing advance. What I have found is most older factory engines. like about 32* timing at full throttle.

Which would mean we could set the base timing at about 8* to get our optimum wide open timing.

The part that really kind of bugs me is the slow rate that Hudson applied the timing. Basically you have no timing advance at all until the engine hit 1600rpm.

Normally you like to bring the timing in faster at a lower rpm and the taper it slower as the rpm rises. This gives a little better drivability by getting the car out of the hole a little faster.

The vacuum advance is used to improve that around town drivability. It is only applied at part throttle applications so around town and light throttle on the highway. Once you put your foot down the vacuum adv is 0*

In the spec sheet we have 2* at 10.5"hg and 8.5* at 14"hg which gives us 4* and 17*

So if we are driving down the highway at 4000rpm we will have the 24* mech adv added to the 17* vac adv plus any base timing we set.

which if my math is correct we will have 41* timing and if we set the base timing at 8* will give us 49* max timing under light loads.

So now that we have discussed all the basic operations of the distr adv.......

What are you guys running for timing and has anyone retuned the curve in their distr?

Here is a table representation of combined timing specs with no base timing added.

0

Comments

-

Bill, do your set-ups have the capability for feedback control of the advance by using a knock-sensor?0

-

Ken- all good points. That's one of the big questions.....what is overly advanced?

Grim- yes a knock sensor can be used with the system. But that brings with it a lot of variables. The sensor is just a microphone the actual frequency of the ping is set in the ESC-electronic spark controller. The frequency is specific to cylinder volume so matching a factory GM module to the flathead would need to be trail and error.

Other factors are engine noise, mechanical lifters, headers...anything that causes a noise that can be mistaken as knock.

Once the basic timing curve is set you can still power tune the EFI timing just like a standard points and carb system as described in the factory manual.

Just advance the timing till it pings and then back it off till it stops.

You didn't need a knock sensor with a carb and you don't need one with the EFI.

I only use them when I develop the initial tuning for an engine.

0 -

I have found the 308 runs best with 20-22 total timing and the stroker motors 16 total. Not sure about the 262

0 -

Russ,

That falls in line with the factory specs.

The 51-54 shows 20* at 2400rpm.

Which is a much quicker curve than the 48-49 specs.

Could be they started learning how to optimize the advance curve in later years or were dealing with some really bad typos in the manuals. I've found quite a few of those already.

I think I will build an advance curve based on the latest specs avail as my starting point and then optimize from there.

Here is a performance chart I found for the 308. It shows the timing at WOT-wide open throttle to be right about 22*. So your numbers fall right in line.

Thanks. 0

0 -

Thanks for the information Russ and Bill.

For the Laughlin Economy Run it looks like the best RPM for gas mileage will be in the 1400 to 1600 RPM range according to the performance chart. Will have to check that against the highest vacuum at those RPMs.

Lee O'Dell0 -

With peak torque right about 1800-2000rpm, that's where I would be looking at gearing for a highway cruise.

Just depends on what your idea of highway cruise is.

0

This discussion has been closed.

Categories

- 37K All Categories

- 117 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 610 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos