Technical advice needed: malfunctioning starter drive

1. This summer my starter drive suddenly jammed on my '37. Pressing the starter button resulting in nothing except dimming of the idiot lights. I was unable to turn the starter shaft by hand, or move the Bendix at all. When I loosened the starter bolts the drive would un-jam, But as soon as I pressed the starter it would jam again.

2. I took the car to my favorite auto electric shop. They told me the Bendix drive was bad.

3. I purchased a rebuilt Bendix from Oklahoma Starter Alternator & Parts. The auto electric shop checked out the entire starter, mounted the Bendix, and gave me back the starter. I re-attached the starter.

4. After that, about 30% of the times I hit the starter button, the starter would freely spin without engaging the flywheel gears. Eventually it would engage -- especially if I started the car in neutral with the clutch pedal released.

5. Two days ago, during a long trip, the drive once again jammed when I pressed the button. I had to unbolt the starter once again, to free the Bendix. Fortunately, after I'd done that the starter started the car just fine.

Can anyone please suggest the reason(s) that this might be happening? I would think that the electric shop would have noticed if there was anything mechanically or electrically wrong with the starter, but I could be wrong. And, there is always the possibility that the Bendix was not correctly repaired.

All suggestions will be appreciated!

Comments

-

These are studs, and moreover there has been no change (for 30-40 years) in the fasteners.

However, the Bendix rebuilder just answered my e-mailed inquiry about the problem. He asked if the shaft itself has any play. I just checked and it does (out at the drive end), maybe 1/16" I'm not sure how that would affect the problem.

0 -

My guess is same as Ken-U.....Those ring gears eventually get badly worn at 120 degree intervals, the position that the crankshaft tends to stop at each time you shut it down. Take the lower shield off of the flywheel/clutch housing and have a look. I suspect you will find three places that have damaged teeth, about four inches long each.

Or I'm wrong.

F

0 -

Thanks, I'll pursue that.

Let's suppose that I find badly worn gears. Would there be any way for me to "clean those up" with a file?

Is just a visual inspection conclusive, or is there some "test" I can do to see if worn gears are indeed the source of my problem? (For example, could the wear be on the starter drive gears?)

I tried rocking the car in gear when the starter "bound up" with no luck. If the problem is indeed worn flywheel gears, would that explain why rocking the car in gear, did not release the starter drive? Or should rocking the car have released the drive, if worn gears were the problem?

Would the worn gear theory explain why, when I hit the starter button, the motor often merely spins freely with no starter drive engagement?

Assuming it is the ring gear, and I can find a good replacement ring gear, what is required to replace it -- removal of the transmission?

Many thanks for your thoughts.

0 -

We don't have the luxury of heaps of spares in Oz so I've used heat to expand the ring gear to remove it from the flywheel. Put the flywheel in the freezer and the ring gear in the oven. Once "She who must be obeyed" finds out what you are doing you are ready to mate the two pieces together offset from the original position by 180 degrees. The starter drive will always be engaging on a seemingly new part of the ring gear and you'll have a dinner time story she'll bring out to say what she has to put up with.0

-

Thanks, but I'm hoping the problem lies elsewhere than replacement or rotation of the flywheel.

To get the flywheel out I must remove part of the floor, the radiator, headlights and grille shell (and hood of course); then remove the entire engine with bellhousing and transmission attached. That is before, of course, I remove the transmission and bellhousing from the engine.

So naturally I am going to pursue every other avenue until all other possibilities are exhausted, before turning to the flywheel!

0 -

You do not have to take the engine out to remove the flywheel, just remove the bell housing, clutch and flywheel. Jon, have you examined the spiral on the Benidx drive? Sounds to me like it could be gummed up with greae and dirt.0

-

It almost sounds like you have two problems at once, however, the sticky drive spiral could be the cause of the ring gear damage and may have occurred before the drive was replaced. Jamming of the drive on the ring gear is almost certainly a result of badly chewed up ring-gear teeth. Cooking the gear off and rotating it 60 degrees (or 180.....no difference) might make initial engagement normal but if the ring gear teeth are bad enough to cause jamming, it won't help in the long run. That condition will become evident as soon as Jon assesses the condition of the ring gear. It's too much of a project to do anything less than make it right. Just take the bottom cover off and look. Rotate the engine by hand from beneath if you need to see more teeth.

F

0 -

Thanks for all your thoughts. I may remove the starter and carefully examine it, especially the drive spiral. (However, it's hard to imagine that it could have gotten very dirty or sticky in the 2 short months since I replaced it....as opposed to the 42 years I drove it, no doubt full of crap.)

And of course I will remove the flywheel cover and carefully look at the condition of the gears (though frankly I'm not sure I know the difference between a slightly worn gear and a normally worn one!).

The fellow who sold me a rebuilt Bendix gear, suggested I check the shaft for end play, also note whether the shaft is bent (this is the starter with no "nosecone", just a shaft that sticks 6" out the back.

It was also suggested to me that due to the unique design of the mounting studs, I need to make sure that the bolts on the back of the stud are tight -- not just the ones at the front which hold the starter. And it was suggested that if the bellhousing bolts are not tight, the bellhousing could be askew, and that might affect the mesh of the gears.

0 -

Jon,

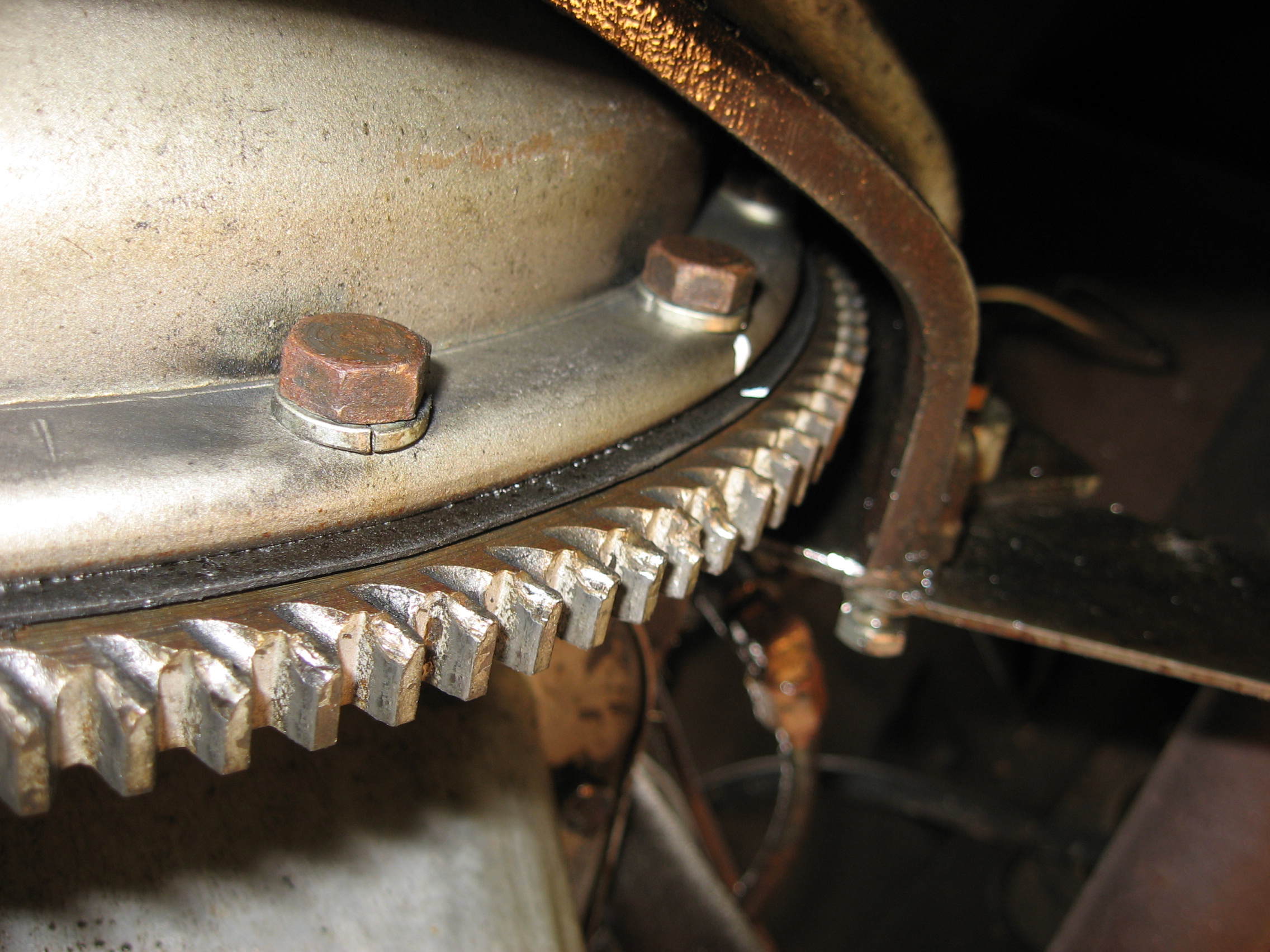

Though this photo of a flywheel is not the same model as yours, the general wear and damage is evident.

The second photo shows an unused flywheel.

Rob

0 -

Jon,

Correction; the second photo shows a nearly new flywheel, it does appear to have very light use.

Rob

0 -

Thanks, Rob. Having looked at the first photo I would have thought it was in good shape! Now I know what to look for. (Can these things be welded on the car, then machined with a file, if it's just a couple of teeth that are bad? Replacement would be a major operation.)

0 -

JOn,

If that the case, it's not just a few teeth. It will be a stretch of about 4 + inches long in each of three spots, 120 degrees apart. One as bad as the one in Rob's photo can't be "fixed" by the ring gear rotation method.....it's just too gone (note the teeth visible in the uppermost area of the starter mounting hole).

If yours is sometimes failing to engage, it's probably that bad. Bite the bullet. It's gotta go.

I hope I'm wrong.

Frank

0 -

In the first photo, the second tooth is cracked on both sides down into the bolt hole and you can see the that the starter has already loosened that tooth. It would probably fall off if the bo

Rob thanks for showing the photos.

Lee O'Dell0 -

if the "bolt were removed."

I guess my computer has a mind of its own by not posting this before.

Lee

0 -

Adhering to my usual opinion that almost anything is possible, I must say that the notion of welding/repairing a ring gear in-situ is probably possible but not at all practical.

Lee, I believe you are seeing a stamping or other mark on the gear and not a crack. Possibly just whacked with a slag hammer or such.

F

0 -

Frank, I believe you are correct. When I click on the picture now it's twice the size than before, and more detail is visible.

Thanks, Lee0 -

The one in the photo, if Hudson, is a Hydra-matic flywheel with the teeth integral with the wheel.......a bummer if you have one in that condition. I have several. I've been contemplating tooling up to repair those as the replacements become more and more scarce. Hessleman got the last new one on the planet.

F

0 -

Okay, I removed the flywheel cover and checked the ring gear teeth today. Everything seemed okay except for two or three teeth that are partly eaten away:

The chipped teeth are toward the right (we're under the flywheel looking up). I'd say almost half the outer surface (furthest from the center of the flywheel) was removed. I did notice some rough edges and burrs, and using a small, fine file I got into the teeth and smoothed things up. I'm hopeful (though not convinced) that the teeth on the Bendix had become enmeshed in the burrs and that removing them might help not to jam up the starter drive next time.

As to the rest of the possibilities:

1. Someone suggested that the starter motor was maybe mounted incorrectly because the nut on the inside of the mounting stud wasn't drawing the stud tightly into the flywheel. But the studs seem fine and the motor snugs right up to the motor plate or bellhousing.

2. The motor shaft seem to have a very slight wobble when I run the motor out of the car, but we're talking about maybe 1/32" out of round...or less. There is definite vibration when it free spins, on the workbench.

3. The Bendix drive is new. There is a spiral cut in the motor shaft under the Bendix, but the spiral portion is not greasy or dirty. Overall, the Bendix seems to move smoothly though frankly I'm not sure exactly how it's supposed to move.

4. I'm scouting out a new flywheel with ring rear, or the ring gear itself, assuming that I will need one sooner or later. A friend may have a NOS one but he's a couple states away from me, and only has a '36 Hudson flywheel to compare his NOS one to. Does anyone know if the '36 and '37 Hudson / Terraplane ring gears / flywheels interchange?

So there we are. If anyone has any further suggestions I'd like to hear them. It's very frustrating to think that I'm going to have to have the engine pulled out just because of this one or two chipped teeth! Especially frustrating if the "jamming" problem turns out to be the result of some other component!

0 -

Is this the only area of the ring gear you have looked at? There are two other places, 120 degrees either way from what is in the photo that may be worse than what you are seeing at this point. Moot point, really, since the visible area is bad enough to be suspect and ring gear replacement is a good idea. I find it odd that the damaged area is pretty much limited to those the two teeth. It usually spans about 4 inches, gradually worse from either end toward the middle of that area. I have a difficult time believing that those are the only bad teeth......but I've been wrong before.

Rotate the crank 120 degrees and have another look, then another 120, if you haven't done that already. If they are, in fact, the only bad ones, I'd consider your suggestion that they could be welded up and hand dressed to the original profile......or close to it. I'd do it. What's to lose?

The engine doesn't need to come out in either case, as Geoff pointed out earlier.

F

0 -

The one in the photo, if Hudson, is a Hydra-matic flywheel with the teeth integral with the wheel.......a bummer if you have one in that condition. I have several. I've been contemplating tooling up to repair those as the replacements become more and more scarce. Hessleman got the last new one on the planet.

That would be great, Frank. A much needed service, but don't think there aren't any more out there. Wildrick probably has 4 or 5 dozen in stock.

0 -

Jon-Look forward to find out what you find when you rotate it around on the other 120-degree spots.0

-

Thanks for the thoughts, but I carefully rotated it in 6 inch increments, marking the flywheel with White-Out as I did to make sure I didn't skip anything. Those 2 or 3 teeth were the only bad ones I found.

I read somewhere on the internet that, until one can replace the flywheel, a good temporary fix would be to stall the engine (when turning it off) instead of merely turning off the ignition and letting the engine stop come to rest in its usual place. That is, turn off the ignition then put the car into gear and let out the clutch while holding the brake. (Slight lurch.) I guess the idea is that the broken teeth always happen where the engine usually stops, so if you stall the engine you'll stop short of that place.. This is of course only a stopgap but could prevent the problem from happening until I replace the flywheel or ring gear.

Of course, if you're crossing a busy intersection and the car stalls, you don't always have that sort of option. The engine would stop with the broken teeth sitting right at the location of the starter drive, which might then bind when the starter button is pushed. With very embarrassing results.

After filing the burrs off the chipped gear, I repeatedly hit the starter in short bursts, to make a full revolution of the flywheel and "find" the bad teeth. The starter did not bind up. Probably wasn't a "fix" but I may still drive the car (with caution) while waiting to find a NOS flywheel.

0 -

Jon, a competent technician with an arc welder and a disc grinder can build these teeth up and grind them back to the correct profile. I have done this on my Essex, and several other cars. Can be done with the flywheel in place.Geoff0

-

Thanks, Geoff! Now, to find a "competent technician"!

0 -

Just make sure the welder connects his ground cable to the flywheel NOT the block! A well meaning welder attached a broken crank pulley on my VW back in 1962. He used the bumper for his ground. One day later my main bearings seized up and froze the engine. DUH!!!0

-

I'm baaaaack!

No problems lately with the starter drive jamming in the flywheel, but I've had numerous instances of pressing the button and having the starter free-spin. This goes on maybe a dozen times, then the Bendix finally engages the flywheel gear. (If I get out of the car and rotate the Bendix slightly by hand, it will finally engage next time I hit the starter.)

THIS does not sound like it's caused by a couple of chipped teeth on the ring gear -- or does it?

When the starter free-spins, if I hold down the starter button, the starter gets going so fast that it vibrates really hard. Could that mean something? Is it supposed to, or could a bent shaft (or worn bearings) be the culprit here?

Again: the Bendix was purchased rebuilt from a company in Oklahoma this spring, and then installed locally by a reputable auto electric service, so my gut feeling is that it's good.

I guess my next move will be to remove the starter and take it back to the electric service and ask them if something is wrong!

0 -

Thanks for this piece of information, Ken!

0

Categories

- 37K All Categories

- 117 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos