Connecting rod bolts for 308's

Comments

-

http://arp-bolts.com/ They have the correct rod bolts. Give them a call.0

-

I think Randy Maas carrys ARP. The Rods need alignred in a spl Fixture to install properly. Dont do at home

0 -

I always have my machine shop check the connecting rods. Here is some info-

http://www.enginebuildermag.com/2007/10/back-to-basics-reconditioning-connecting-rods/

"After the caps are torqued on with acceptable rod bolts, measure the big end bores. This will help you to determine how much to take off the caps and what size you’ll need to hone them to. In general, you want to take off as little material as possible to make the bore round again. Experts say you should not take off more than .002" of material off the big-end at a time. After you hone the big end, measure the rod to see what size bushing you need to put in the pin end.

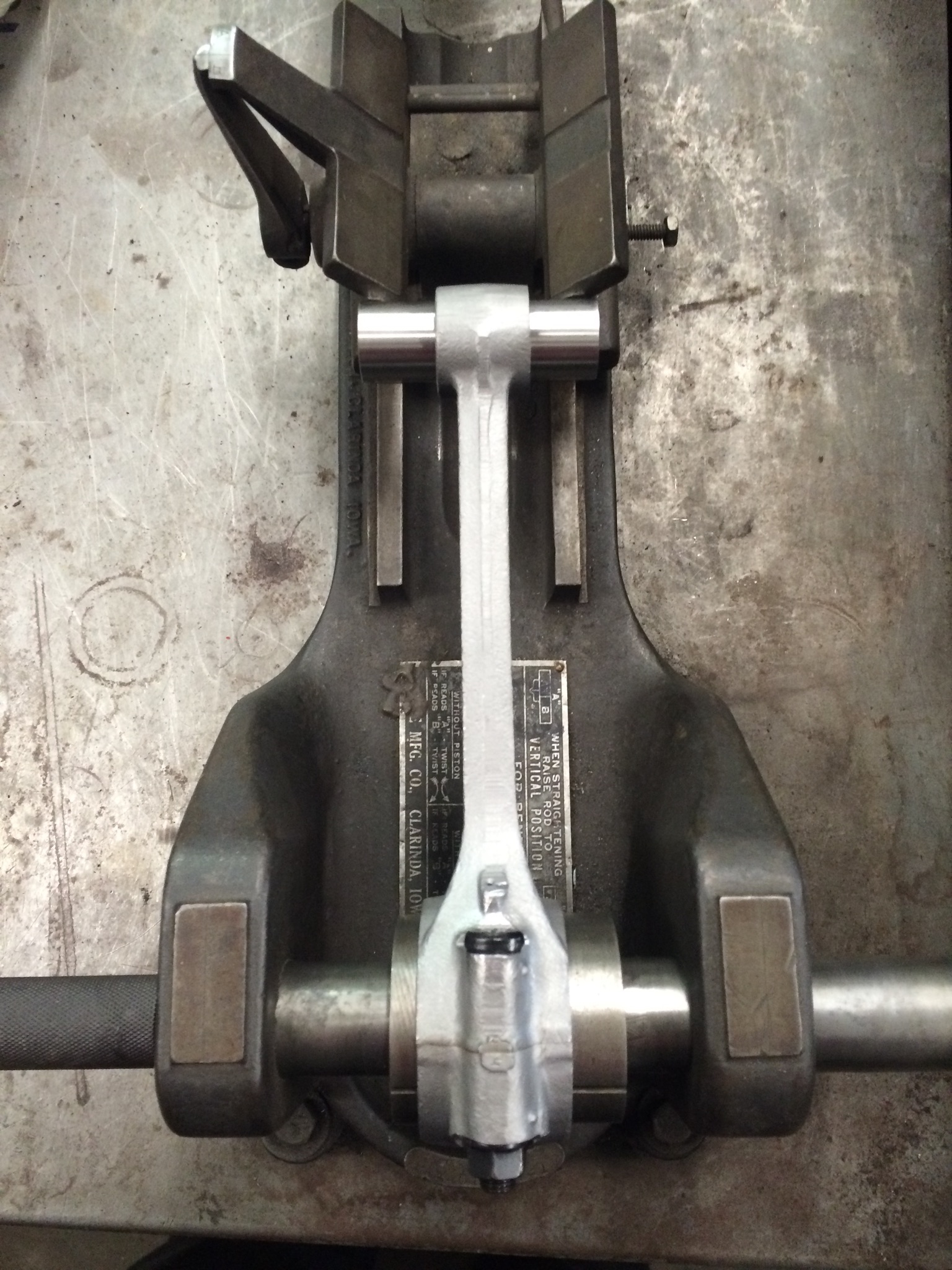

If during the inspection process a bent or twisted rod is found, it may be possible to straighten. One method of correcting bend or twist is called cold bending. This can be achieved using a special holding fixture. When performing this procedure, it is important not to nick or scratch the rod, caution experts. Nicks and scratches weaken the connecting rod and may lead to possible breakage.

Experts say you must first determine the direction of bend or twist. Most bends in the rod will be located near the small-end bore. Place the connecting rod into the straightening fixture using the correct size big-end and small-end adapters. Install the cap and torque the cap bolts to specifications. Select the appropriate bending bar. It should closely fit the rod to prevent nicks and scratches. Use the bar to bend the rod in small increments. Measure the progress on a rod alignment fixture.

Once the connecting rods are straightened, bored and honed, then you can put the proper size bushing in the small end, which is a very important step according to some engine builders. It is recommended that you press out the old piston-pin bushing and install new ones. And to ensure that the bushing won’t rotate, you should expand it to conform to the small end bore. To expand this bushing, press a hardened steel ball through the I.D. of the new bushing. This will lock in the new bushing and prevent it from spinning in the bore. If you heat the rod to install the new bushing, you should allow it to cool before you expand the bushing with this broaching technique. Then grind the cap to the correct center-to-center dimension and hone the big end and install new rod bolts."0 -

More info I found on the net ----

"I am going to rebuild my Hudson 308 rods and plan on using ARP

Ford 351 Cleveland rod bolts.

My question is what size do I need to ream the rod bolt holes to

for the 351 Cleveland rod bolts? "

"answer- I finally got my numbers verified by the machine shop. Reem the rods to .002 to .003 under the rod bolt shank size for a press fit. The caps should be .0005 to .001 oversize for a slip fit.

The last time I had the crank out of my race car, I had the snout turned down (I think 1/16" undersize) to match smallblock Chevy. Then I bought a Chevy fluiddamper for it. My local bearing house supplied me with a timing cover seal with the right ID and OD to match." Danny Spring -----0 -

Reaming Hudson Rod for ARP 190,000 psi Rod Bolts

"Uncommon Engineering"

0 -

Call my father (Randy Maas)to do them correctly!

0 -

Would suggest installing pin bushing and honing to size and cutting caps and hone to size before straightening rod.Kdancy said:I always have my machine shop check the connecting rods. Here is some info-

http://www.enginebuildermag.com/2007/10/back-to-basics-reconditioning-connecting-rods/

"After the caps are torqued on with acceptable rod bolts, measure the big end bores. This will help you to determine how much to take off the caps and what size you’ll need to hone them to. In general, you want to take off as little material as possible to make the bore round again. Experts say you should not take off more than .002" of material off the big-end at a time. After you hone the big end, measure the rod to see what size bushing you need to put in the pin end.

If during the inspection process a bent or twisted rod is found, it may be possible to straighten. One method of correcting bend or twist is called cold bending. This can be achieved using a special holding fixture. When performing this procedure, it is important not to nick or scratch the rod, caution experts. Nicks and scratches weaken the connecting rod and may lead to possible breakage.

Experts say you must first determine the direction of bend or twist. Most bends in the rod will be located near the small-end bore. Place the connecting rod into the straightening fixture using the correct size big-end and small-end adapters. Install the cap and torque the cap bolts to specifications. Select the appropriate bending bar. It should closely fit the rod to prevent nicks and scratches. Use the bar to bend the rod in small increments. Measure the progress on a rod alignment fixture.

Once the connecting rods are straightened, bored and honed, then you can put the proper size bushing in the small end, which is a very important step according to some engine builders. It is recommended that you press out the old piston-pin bushing and install new ones. And to ensure that the bushing won’t rotate, you should expand it to conform to the small end bore. To expand this bushing, press a hardened steel ball through the I.D. of the new bushing. This will lock in the new bushing and prevent it from spinning in the bore. If you heat the rod to install the new bushing, you should allow it to cool before you expand the bushing with this broaching technique. Then grind the cap to the correct center-to-center dimension and hone the big end and install new rod bolts." 0

0 -

Anything else would be a waste of time, not to mention the need to repeat the process afterwards. Straightening is the final step in rod refurbishing.

Frank

0 -

I sent the editor of the on-line mag a note with your replies. Lets see what his response is and if they will make a correction!

My machine shop straightens the rod as the final step of refurbishing.

0 -

Why is the rod straighten last?0

-

The process of clipping the rod & cap, honing the "big end" back to spec, then installing & honing the upper end bushing can and does introduce an inevitable degree of misalignment that needs to be corrected by straightening. If straightening was done prior to any of the first steps, another bit of misalignment can (and will) occur. I check/bend, check/bend, check/bend numerous times (depending on the amount required) and the final step is to "overbend" and return to relieve the stress in hopes of it NOT changing by itself afterward. Sometimes this causes a need for repeating the exercise a time or two.

Precision for this operation is measured in tenths of a thousandth and can be a tedious, time consuming step, but is absolutely necessary. Imagine a piston to cylinder clearance of two thousandths and a rod cocked by 10. The upper and lower rod ends must be parallel within a thousandth or so to be acceptable in a stock engine and more critical in an ordinary application.

Frank

0 -

Oh.....additionally, the chances of a used rod (and sometimes even a new one) being properly aligned to begin with, are quite slim.

We check for twist as well but it's less important.

F

ps

The last line of the previous post should have read, ".....more critical in an engine built for high performance."

0 -

Thanks for all the info fellas. I'll make sure I check everything out before I get to far along.0

-

Kinda makes you wonder why some of those people "get the big bucks". Why would a Sunbeam Alpine need P/S anyway?

F

0

Categories

- 37K All Categories

- 117 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos