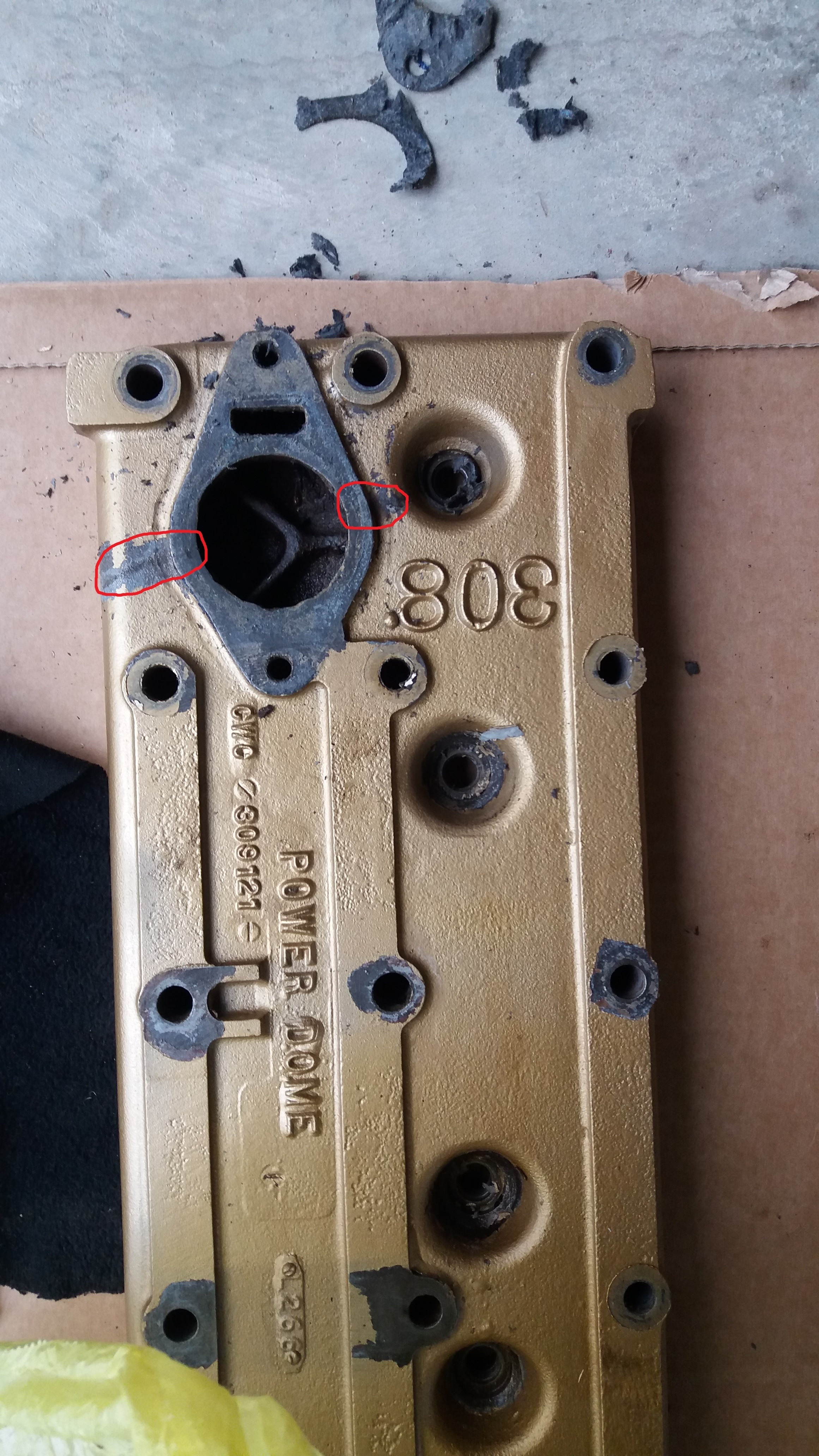

oh no!....308 cylinder head cracks....

Hello Hudson folks,

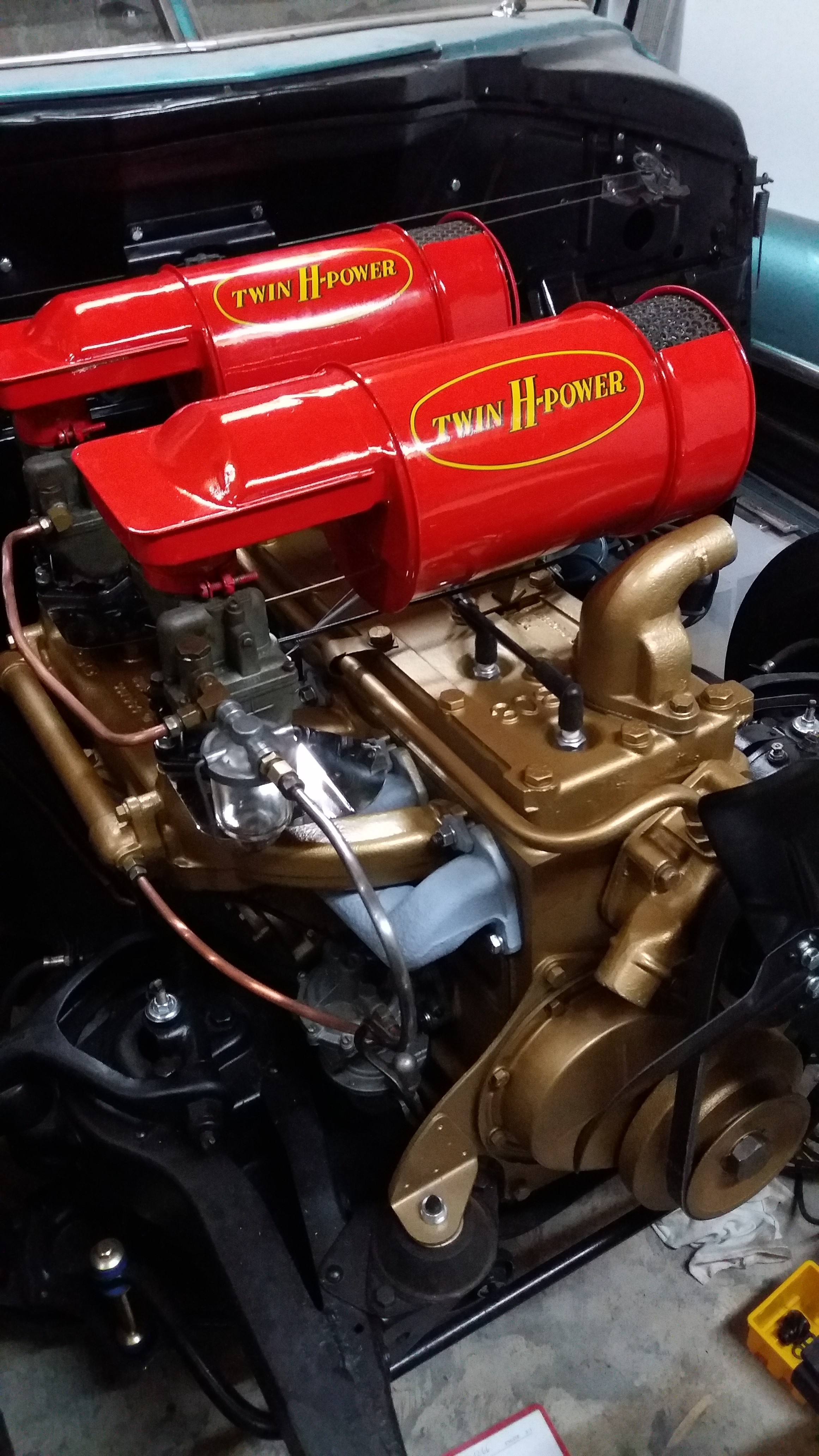

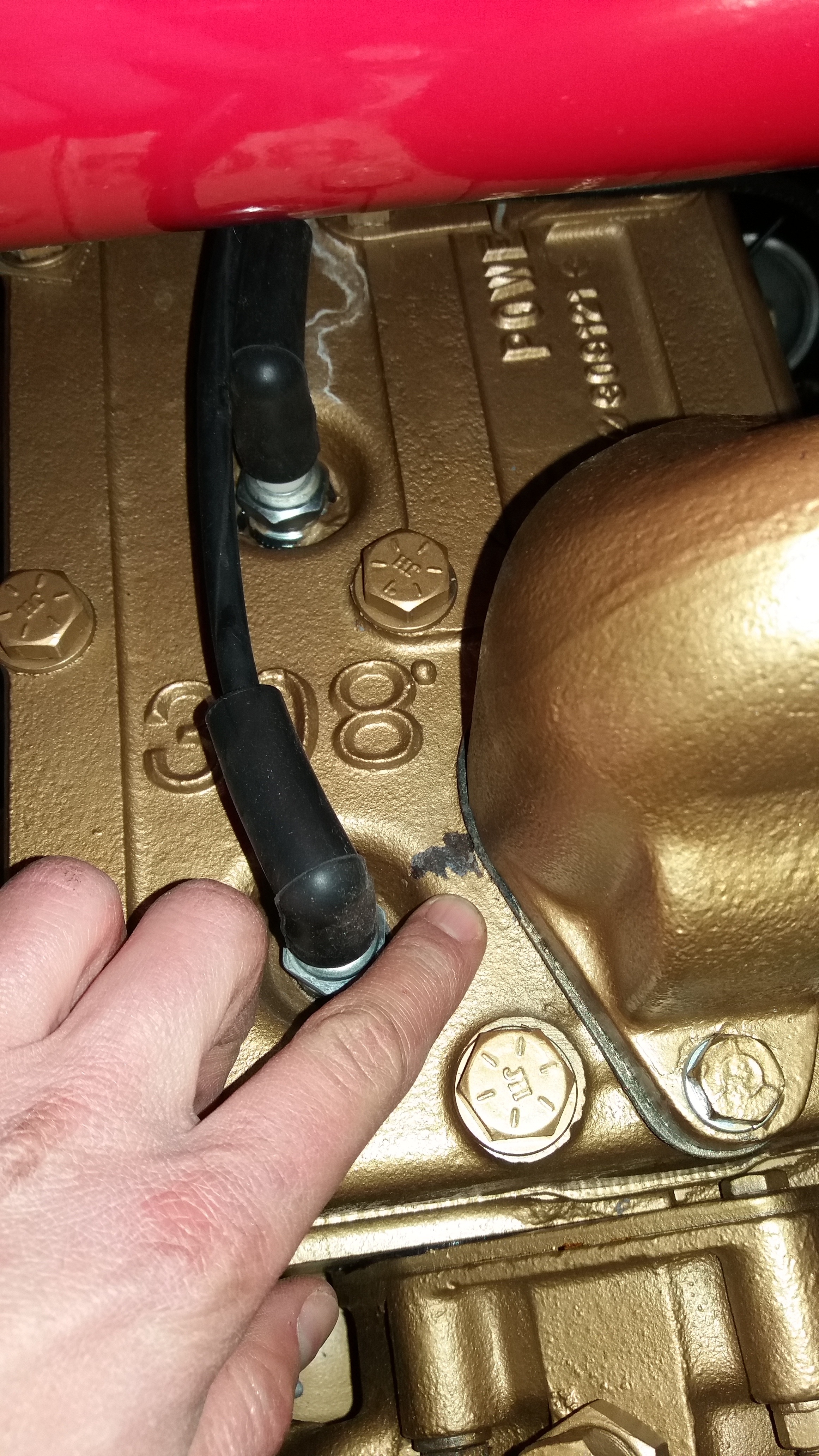

i´m in slow progress of restoring my 1952 Hudson hornet club coupe....sidetracked from family things, other carprojects and, and and....but i want to keep track on my Hudson project. The engine got a full rebuilt. Two days ago i started it the first time....before i started it i recognized that there were two drops of water around the water neck (thermostat housing). I thought i will retorque the two screws later. I fired it up....and it ran...little adjustment with the timing gun and little adjustment on the carburaters...i was happy...but then the dilemma....i recognized that there are two little, little cracks around the thermostat housing (see pictures). That was annoying! Today i disassembled the head and cleaned the two spots where you can hardly see the cracks. This week i will go to my machine shop and ask for a practicable solution. What are you thinking? What are your experiences? New„old“ head? Laser welding? Has someone a good usable crack free head (308)?

Thank you so far! By the way...the Hudson has to hit the road this summer! I will keep you updated with pics.

Hudsonly, Marco

Comments

-

Those cracks are in a bad place. They can probably be welded up with cast iron rod ni-rod , worth paying for the good stuff, run around $8 - 10 per rod. Drill the end of the crack , grind a v where the crack is. Heads are difficult as the thickness varies everywhere. Was the head cracked checked? Good luck, put stop leak in it when you get it back together. Actually "bars leak" would have stopped it for a while.0 -

I had a machinist weld up a crack in a 51 wide block manifold using a technique called "powder welding." Perhaps it will work for your head. The link is to a video using said technique.

https://www.youtube.com/watch?v=71amiAPXBn0

Good luck.

0 -

Extra heads are easy to find.

0 -

If you get another head make sure the vendor guarantees it to be in spec and machined flat. Hard to find a used "in spec" head. I've had to send two back to vendors because they were out.

It should measure no less than 1.94" after planing. Measure in several places, both sides and ends. If you go with a 262 head ( in spec) make sure to check piston clearance in case you need to change spark plugs due to electrode to piston clearance. Sometimes you can get by with using a thicker plug washer to raise the plug up to give more clearance.

0 -

I have 308 heads if needed.0

-

First of all thank you for your help and good advice. A lot of knowledgeable people in this forum. I appreciate that! Tomorrow i will go to my machine shop....but i tend to buy another head.

@Nevada Hudson....probably they are easy to find....but not in Germany!

So it has to be a head that is "in spec" and of course crack free. No broken studs...and all the threads should be o.k. I don´t want to have another "wall hanger". I will keep you updated.

Thank you all, so far.

Marco0 -

Marco please send me your email address. I've tried twice to reply to you to no avail. It keeps bouncing back. thanks.0

-

I never seen a crack on top before. Weld may work but best replace with a good 3

08 or 262 so no worry. There are a lot around in U.S. to ship.....

0 -

Marco, Thanks.0

-

you have a beautiful looking motor there. I suggest you try jb weld . Its in an easy area to get at and this stuff works well. we used it on the side of a block with a six inch long crack on the water jacket. ground an eighth inch groove . applied the weld [used a heat lamp over night]. never leaked, even in this crucial spot. this stuff really works!0

-

...beside other problems on my Hudson i still have to struggle with the cracks on my 308 cast iron cylinder head. I don´t want to mess with it anymore. So i want to buy another good usable crack free cylinder head (in "spec"). Since i´m in Germany i saw here a aluminium head for sale. What are your opinions on that head? It´s a "power dome 500". I don´t really need a "performance" head...just want to have a good running engine.

0 -

No answers here but I’ll say the work and detail in pics are very nice. How about pic of ride0

-

Marco, At the risk of incurring the wrath of the Alcoa head Hudnuts, I will say that the origional production of the aluminium heads was at best fair . I have aluminium heads that are wall hangers.I won't go into their problems here but suffice to say there really isn't much advantage in having an origional one. There are decent reproduction heads made of aluminium but they were/are not made by Alcoa. If you desire a decent 308 iron head you can get them from several sources. I have a number if interested.0

-

I have one from a '56 308 on my '54 and it seems to be a good quality casting.0

-

Isnt the "500" head a narrow block head? The 308 would be a wide block.0

-

500 head won't fit as Kdancy noted0

-

FYI

I suggest buying another308 or even a 262 Head rather than try patching your cracked head, if you can find either one in your Country... You need a Head with the Number 308 or 262 embossed on the front top.... If not in your Country, I have heads as well as other Forum Members.

Regarding Freight,

Ive heard people overseas send Parts bought in U.S. to a Container at a U.S. Port to be placed in a large Shipping Container along with other peoples parts to save individual Shipping Costs. I assume it takes a little longer but its a big saving on heavy parts. Perhaps check into that possibility to get a head shipped from the US.

0 -

I had a head crack in the same location as yours. I replaced it with a good used one. Didn't feel it was work trying to fix after having to replace the head gasket too.0

Categories

- 37K All Categories

- 117 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos