Valves, Valves, Valves - What to do?

As I’m waiting on my new (old from eBay) Zim valve compressor to arrive, I wanted to see what is being done with the valves in the old 212ci & 254ci engines. First up is my 1937 Hudson 212ci 6cyl, later this summer hopefully I’ll be getting around to the Hudson 8 cyl. From what I can tell 37 is different from 38 on, so one stays with the 37 valve or it means guides, etc.?

From what I have read they were typically ground to 45 degrees. What I’m wondering is if some of you guys may have tried a 3 angle valve job. In searching the internet for information, I ran across Flathead ford guys doing 3 angle as well as the guys with old ford tractors doing 3 angle valve jobs. From what I’ve been learning, 3 angle valve jobs have been done for around 50 years now and the main benefit is to improve the flow of air into & out of the combustion chamber. That has to be balanced with enough surface of the valve touching the seat for proper cooling. Additionally I’ve read of individuals cutting the valve face at 45 degrees and the seat at 46 degrees. The 1 degree of wedging effect will actually help the valve seal “lock down” at its time of rest to help the cooling.

Additionally as I was looking at the valve stems, they are huge, thus has anyone turned down the portion of the valve in the intake, (outside the guides)? I know these are hedonistic ideas on these old splashers but I had to ask!

From what I have read they were typically ground to 45 degrees. What I’m wondering is if some of you guys may have tried a 3 angle valve job. In searching the internet for information, I ran across Flathead ford guys doing 3 angle as well as the guys with old ford tractors doing 3 angle valve jobs. From what I’ve been learning, 3 angle valve jobs have been done for around 50 years now and the main benefit is to improve the flow of air into & out of the combustion chamber. That has to be balanced with enough surface of the valve touching the seat for proper cooling. Additionally I’ve read of individuals cutting the valve face at 45 degrees and the seat at 46 degrees. The 1 degree of wedging effect will actually help the valve seal “lock down” at its time of rest to help the cooling.

Additionally as I was looking at the valve stems, they are huge, thus has anyone turned down the portion of the valve in the intake, (outside the guides)? I know these are hedonistic ideas on these old splashers but I had to ask!

0

Comments

-

when I grind valves rather than just replacing them I grind at 44 degrees for a tighter fit. I have never done a 3 angle grind.0

-

I think the '37-on valves are the thinner stemmed ones, definitely use the later ones not the older thick stem ones! I guess if you really wanted to chase airflow you could undercut the back of the inlet valve a bit too. I decided not to shorten the guides as heat transfer could be reduced too much and valve stem support and control of accurate valve sealing on the seats reduced by side play developing with wear and not really worth it. I did do a 3-angle valve job though.Another heretical thing I did was install NGK B6HS 1/2" reach plugs as I found the 3/8" standard ones were significantly recessed into the spark plug threaded hole using the 112 head. These longer plugs placed the spark in just the right place I thought, with no exposed threads on the plug. Clearance testing showed plenty of clearance to the exhaust valve. They are burning a perfect colour now with no overheating.The result was pretty good, causing the clutch to start slipping a bit under full power in second. The speedo needle really springs around the dial with alacrity when you floor it in top (30-50 in 7 secs flat) which isn't far behind the Terraplane Eight tested when new at 6 secs. I still have the free flow exhaust to do and a better carb.Note on the earlier 212's at least they were undercarbed, proven by evidencing the significant vacuum they pulled at WOT (connect up your vacuum gauge to the wiper port on the manifold and run it through into the car temporarily so you can see what is happening).Check your valve followers too as they can get grooves cut in them by the cam.

0 -

Excellent advice, but possibly one typo. 36+37 valves are the "fat stems". Go for the 38 -47 valves and guides.0

-

Terraplane8, that’s interesting you mentioned the spark plug change to a longer reach plug as I too had noticed the shrouding of the plug in the head. Last night I was searching on-line for any information about a longer reach plug to use in my stock 212 head, as well as other vehicle makes which may have seen a similar situation. Heres a photo of just how recessed the Autolite 295 plug (3/8” reach) is in the combustion chamber.

From what I‘d been reading its ideal to have the plug down farther, ideally having the threads of both plug & head match, as you had done. When the plug placement is recessed there can be problems as the spark becomes shrouded and power can suffer.

“A significant mismatch between the spark plug and hole thread can cause detonation-promoting hot spots. If the plug protrudes too far into the chamber, piston interference is also a possibility. If the plug is recessed into the hole, this could shroud the spark, calling for more ignition lead than normal.” HotRod Magazine

https://www.hotrod.com/articles/hrdp-1005-spark-plug-reach-tech/

This is a great example of knowledge which needs to be shared & preserved for future owners. I’m sure it took quite a bit of time & effort to research the recessed plug position you had seen to find a proper replacement plug. As well as Terraplane8’s experience with rebuilding of his splasher 6 with the 112 milled head!

https://openforum.hetclub.org/discussion/114333/36-terraplane-with-high-compression-report

Great stuff Guys!!!0 -

I can can supply recently made 18mm Long Reach KLG "ML50" spark plugs should an 18 mm spark plug be appropriate. This is what we use in our 28 Essex

0 -

The other thing is not to over-torque the head nuts as the block casting is thin around some of them and you don't want to pull them out or cause excessive distortion. I resisted the temptation to wind them up a bit tighter and so far all good.Have you mentioned your cam followers? These can be ground to a wider radius I have read which improves the cam timing a little. The real experts hopefully will add detail to exactly what is desirable here.For a flathead the combustion chamber design looks good, with half the piston diameter being part of the squish area. If I got really carried away I would infill weld and blend a little in the high part of the chamber to compensate for optimisation of the transfer area between the piston and valves - plenty to think about here!0

-

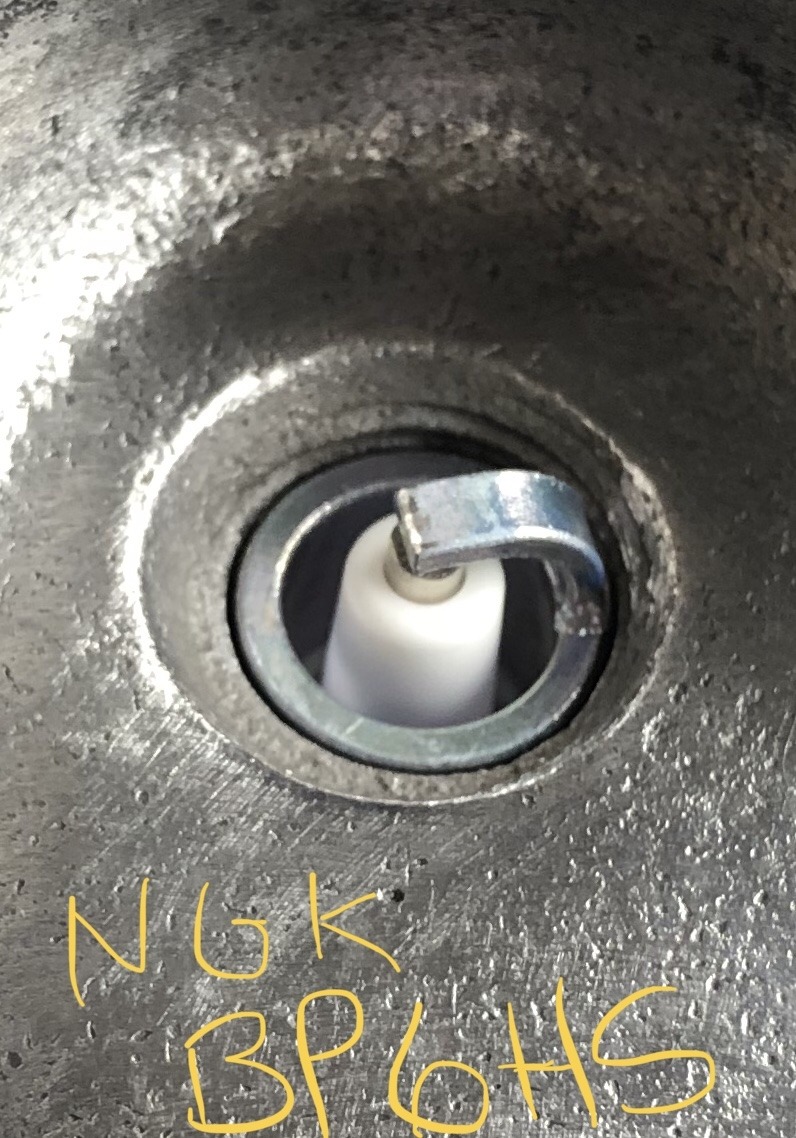

I took some time today & ran over to NAPA to try two NGK plugs; B6HS & BP6HS. Looking at the specs on paper & trying to apply them vs seeing with one’s eyes was definitely worth the trip.

Both of these plugs are the same heat range as the original Champion J8 (or current Autolite 295 that I’ve been using), both are non-resistor plugs with copper and not any modern platinum, iridium, etc. (If resistor plugs are needed then use NGK BR6HS or BPR6HS plugs.) Also, my head hasn’t been milled or modified. Hopefully these results will be representative of at least the 1937 Hudson 212ci 6 cylinder heads if not more.

As measured on my head, the plug will drop below the chamber ceiling by approximately 2mm, which should not be an issue with the valve as I had more than 7mm of clearance on my engine. (To be safe you may wish to verify this on your engine to be certain it will not be an issue.) In the end I am hopeful the NGK BP6HS plugs will provide some benefits to my old Hudson.

Photos below:

purple play-doh over exhaust valve & plug hole-

New reach vs old reach.

There was so much build up on the threads when I originally pulled the head, I didn’t know there were even threads buried there. After a little sand blasting & thread chaser I could see them all. If you look close at spark plug hole at about 5-6 oclock in the image below you can just make out the ground electrode of the plug.

I like how the threads are matched as they should be & the electrode is moved closer to the chamber. Thanks Terraplane8 for your recommendation of this plug!

Below is the plug I will be trying after she’s back together. This plug is the same as the one above but with an extended electrode, further moving the spark into the chamber.

0 -

Just to muddy the water further: last time my '37 3x5 had an overhaul, I had my mechanic friend install silicon bronze valve guides. I did this on a whim, because the old 3x5's are notorious for having stuck valves, especially when the engines sit for long periods of time. (One is supposed to put Marvel Mystery Oil in the gas to lubricate the stems and prevent the valves from sticking.)

When I purchased my car in '71 the valves were stuck open and I had to whale on them with a hammer -- with the cylinder head removed, of course -- just to drive them back down. They were that "stuck"!

I cannot attest to the success of this upgrade on my part. It's been probably 15+ years since the guides were installed and I haven't been back into the motor since then, nor have I taken a compression check. Maybe regular guides would have worked just as well. But the engine continues to run fairly smoothly so I'm guessing that none of the valves has gotten hung up in its guide and stayed open long enough to burn.0 -

I like your choice of plugs and double checking the clearance....

0

Categories

- 37K All Categories

- 117 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos