How to do Rings on Pistons & Pistons in Cylinders

My rings arrived from Wildrick’s today & not having put rings on pistons or pistons in the cylinders, I’m looking for advice.

My cylinders are standard sized 3.000 thus my rings are also standard. Rings are going back on the stock factory pistons. Cylinders have been honed. Finally Uncle Josh had a good recommendation to use a radiator hose clamp on the single ring lowest on the piston skirt, then use a regular clamp on the upper rings to install the pistons in the cylinders.

Since they are pinned I’m a little concerned about keeping them in the right place as well as not braking any rings as I put them on the pistons.

My cylinders are standard sized 3.000 thus my rings are also standard. Rings are going back on the stock factory pistons. Cylinders have been honed. Finally Uncle Josh had a good recommendation to use a radiator hose clamp on the single ring lowest on the piston skirt, then use a regular clamp on the upper rings to install the pistons in the cylinders.

Since they are pinned I’m a little concerned about keeping them in the right place as well as not braking any rings as I put them on the pistons.

0

Comments

-

Get a set of piston ring pliers, to expand the rings so you can put them on the pistons. Expand them as little as possible.Hold the ring compressor against the piston at the pin, as you tighten it.Might use a tall band type ring compressor as it will work with 4 ring pistons.

0

0 -

I concur as to using a tall compressor that fits over all the rings. Be very careful as you compress the rings, and before you tighten right up, move the compressor rotationally back and forth on the piston to ensure that all rings are locating against the pegs, then tighten thoroughly. I find the best method to fit the rings is to sit the ends of the ring into the groove with the opposite sitting on top of the piston, and then gently push with your thumbs down over the top of the piston until the ring sits in the groove. This for the rings above the wrist pin. For the oil ring at the bottom, sit the ring at an angle and push the ring over the bottom over the skirt and gently work up until it gets to the groove. I find this a better method than using a ring spreader, which spreads it too wide and is likely to break a brittle ring.0

-

Oh, another tip, cut a slight shallow chamfer on top of the bore with a bearing scraper, so that there is no sharp edge for the rings to catch on.0

-

Do you guys oil the rings before you put them on the pistons? Do you oil the inside of the ring compressor or outside of piston to allow easier movement of rings & piston when pushing them into the cylinders? I assume one oils the inside of the cylinder right? What oil do you use?0

-

After putting the rings on the piston, I use a squirt oiler and oil the rings and piston skirt, and spread it around with my fingers to make sure it's all well lubricated. I also spread oil on the bore.If you can leave the rod bolts out as you install the piston, you won't have to protect the crankshaft from them...but modern engines have the pins pressed into the rods, it looks odd to me to see them loose! normally we put a piece of rubber hose on each bolt, before installing the piston/rod assemblyAs for installing the rings by hand, vs with pliers...I guess that's up to you, and how strong and calloused your fingers are. I've done it both ways, I prefer pliers, but yeah, you do have to be careful to not expand them any more than necessary.0

-

0

-

0

-

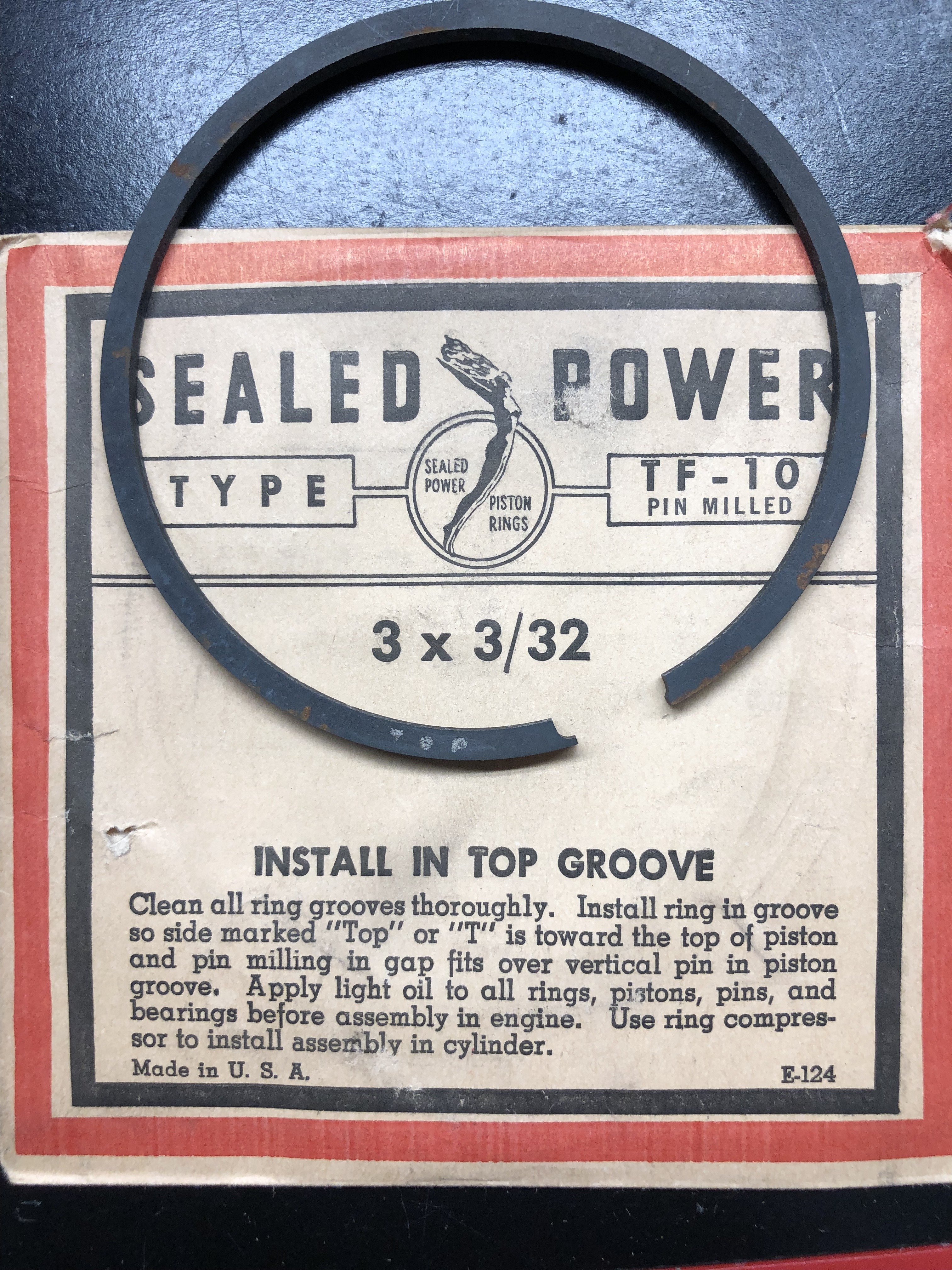

After 80+ years I expected some surface rust and most rings have a little like this shown above. Should I do anything to these rust spots or any other corrosion I run across?0 -

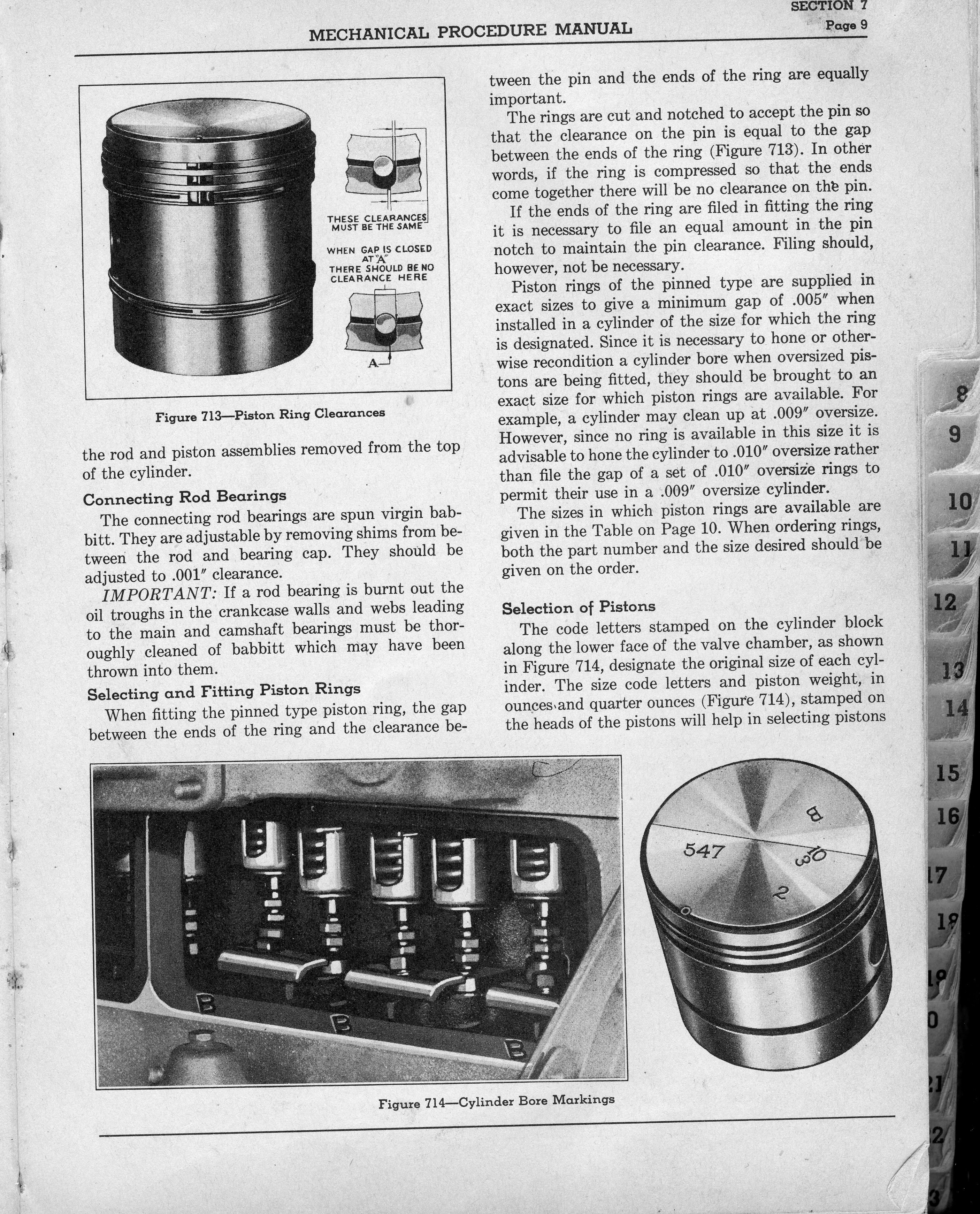

What should the range be for the ring end gap? I assume one can put the ring in the bore, say an inch down from the top & measure the ring gap?0

-

rule of thumb on gap is that you want at least .004" gap per inch of bore size...so on yours, you want at least .012" gap at the tightest place. usually on ring only jobs, not rebores, you don't have any issues with rings being too tight (unless they are the wrong size rings)you could use some very fine scotch brite or other mild abrasive to remove the rust from the rings. The rings need to fit snug against the ring lands, that is what seals the engine (along with the ring face contacting the bore)0

-

Here is a page from the Mechanical Procedure Manual 1938 on piston rings for

information. Hope this is informative.

Ivan L.

0

Categories

- 37K All Categories

- 117 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos

https://youtu.be/y9Dh2K7kAHs

https://youtu.be/y9Dh2K7kAHs https://youtu.be/PbbPXuwDYfE

https://youtu.be/PbbPXuwDYfE