35 Terraplane Transmission question

farmermike

Member

in HUDSON

The clutch went out in my Terraplane last fall and I finally got the transmission pulled to see what happened. The clutch disk hub disintegrated. Ordered a new clutch disk from Ron Fellows but I am trying to understand what happened to make sure it doesn't happen again.

In 2015 I had the flywheel resurfaced, rebuilt clutch disk, rebuilt pressure plate, new throw out and pilot bearings, and had the transmission rebuilt. I have less than 400 miles on the new parts.

I noticed that there is side to side free play in the input shaft of the transmission. Not sure if that has any bearing (pun intended) on the issue but I made a short video showing the input shaft hoping you guys might be able to tell me if that is within tolerances or if that might be part of my problem. The pilot bearing is still in good shape so it should help with that.

You can view it here: https://youtu.be/igrtsTpQAgA

https://youtu.be/igrtsTpQAgA

Thanks guys,

Mike Schlepp

In 2015 I had the flywheel resurfaced, rebuilt clutch disk, rebuilt pressure plate, new throw out and pilot bearings, and had the transmission rebuilt. I have less than 400 miles on the new parts.

I noticed that there is side to side free play in the input shaft of the transmission. Not sure if that has any bearing (pun intended) on the issue but I made a short video showing the input shaft hoping you guys might be able to tell me if that is within tolerances or if that might be part of my problem. The pilot bearing is still in good shape so it should help with that.

You can view it here:

https://youtu.be/igrtsTpQAgA

https://youtu.be/igrtsTpQAgAThanks guys,

Mike Schlepp

0

Comments

-

That has nothing to do with the clutch failing. The nose of the shaft is securely supported by the bearing in the flywheel, so it cannot move when installed. The plate had just reached it's expiry date.0

-

Make sure that you have both of the alignment dowels (sleeves) in place. I've seen this happen when one or both are missing.0

-

Looks like the hub disintegrated as stated - metal to metal contact either as it was failing or after it went out. Could the flywheel or pressure plate have done that ? What caused the grinding destruction ? Don't want a repeat.0

-

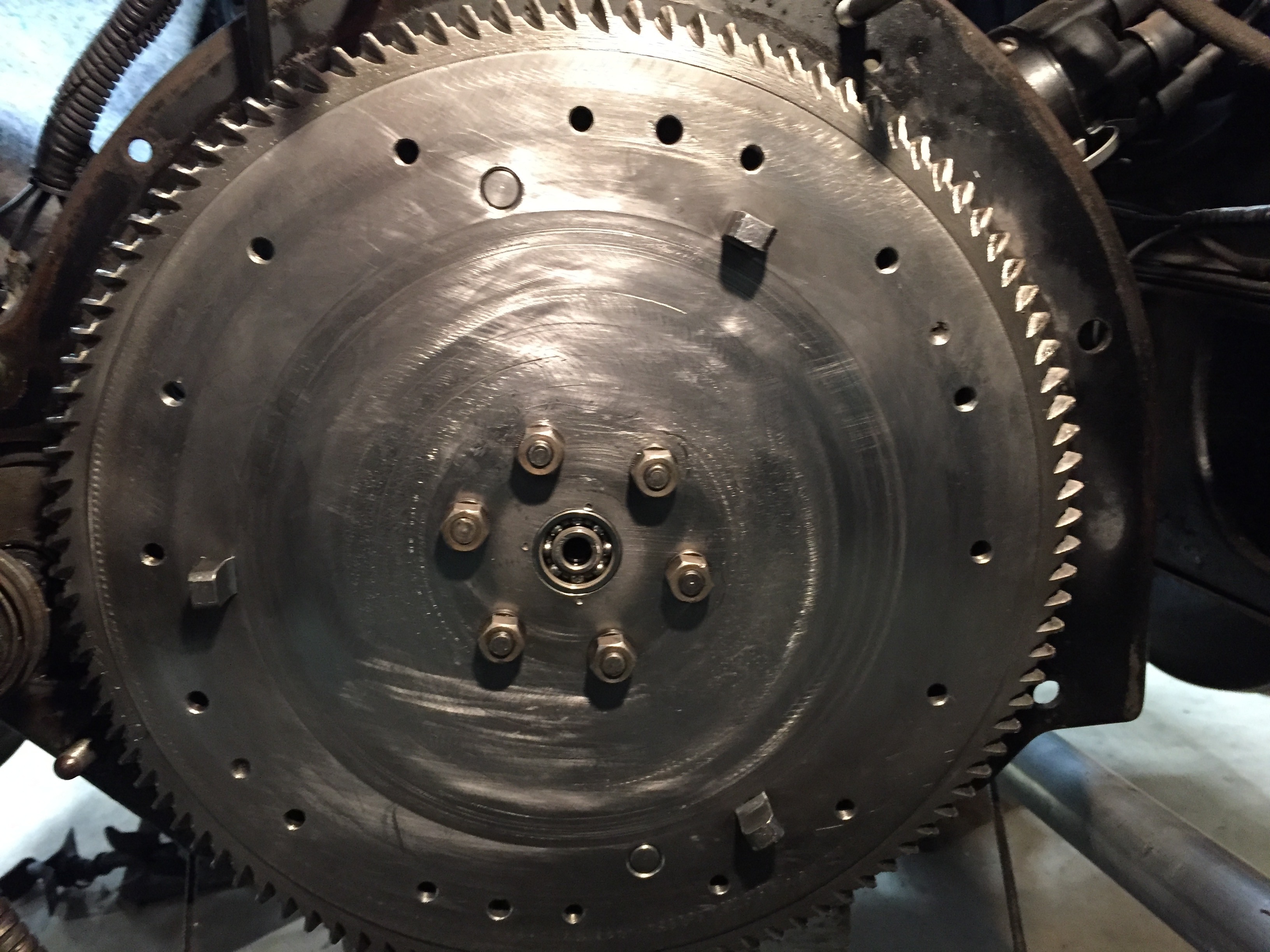

What dowels are those? The flywheel has three tabs (see photo) but I do not see anything else that looks like a dowel on the flywheel or pressure plate.54coupe said:Make sure that you have both of the alignment dowels (sleeves) in place. I've seen this happen when one or both are missing. 0

0 -

I mean the alignment sleeves from the block to the transmission. Sorry, I wasn't clear on that.0

-

I don't have anything that looks like a dowel either on the block or the transmission. Where would they be located?54coupe said:I mean the alignment sleeves from the block to the transmission. Sorry, I wasn't clear on that.

I use two studs placed in the top two holes of the block to aline the transmission to the block while doing assembly so I don't mess up the throwout seal.0 -

These are sleeves that are in two of the bolt holes between the block and the bell housing. Most of the time they stay in the block, but I have seen them come out when you pull the transmission. If you examine the bolt holes on the bell housing, you will find two that are counterbored to accept the sleeves. The block is machined the same way. This is where the sleeves go. If they are not there, the crank and the input shaft of the transmission will cot be alighed, and it will fear the center out of the clutch.0

-

These sleeves are about .620 OD, and probably only stick out about 3/8"0

-

Two of the larger bellhousing bolts go through them. One at a lower corner, and one on the opposite side near the top.0

-

Found the one at the top. There are also two counterbored holes in the bell housing for the starter bolt studs that have a sleeve or shoulder that fits the counterbored holes. On the opposite side of the bell housing from the starter where the larger bolt goes through the housing is not counterbored. Not sure what that is about.54coupe said:Two of the larger bellhousing bolts go through them. One at a lower corner, and one on the opposite side near the top.

Thank you for pointing this out. I was not even paying attention to them.0 -

Thanks, Geoff. I was really hoping I did not have to deal with that transmission again.Geoff said:That has nothing to do with the clutch failing. The nose of the shaft is securely supported by the bearing in the flywheel, so it cannot move when installed. The plate had just reached it's expiry date.0 -

There is only one dowel on the transmissions up to 1940, and that is on the top left (looking from the back). The important thing is the bottom right bolt must be a plain shank 7/16" bolt, and inserted through the engine plate from the front so it supports the bell housing and stops it from moving. If a smaller bolt is used the housing can drop, which misaligns the input shaft with the flywheel, and this perhaps could have led to your failure? Effectively, it means the centre of plate is distorting all the time. Just a thought.

Geoff

0 -

I recently viewed a clutch replacement video showing Doug Wildrick replacing ca clutch in a car at HET nationals. One comment I heard that was the “a ha moment” was... when stabbing the transmission it must be straight in, or the trans will put pressure on the clutch and potentially twist or bend the clutch center! Not saying this is the reason for your failure. But it maybe a contributor...?0

-

Thanks for the information. I will be sure to use a couple guide bolts to help me get it in straight.Glowplug said:I recently viewed a clutch replacement video showing Doug Wildrick replacing ca clutch in a car at HET nationals. One comment I heard that was the “a ha moment” was... when stabbing the transmission it must be straight in, or the trans will put pressure on the clutch and potentially twist or bend the clutch center! Not saying this is the reason for your failure. But it maybe a contributor...?0 -

That 7/16" bolt is ESSENTIAL.

0 -

I think that might have been the problem. I looked over the bolts that I removed and the one in question was NOT 7/16. That will be corrected. Thanks again for all your helpGeoff said:That 7/16" bolt is ESSENTIAL.0

Categories

- 37K All Categories

- 117 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos