Clutch problem

I was having trouble adjusting the clutch on a 48 Commodore. I couldn't get it to adjust out far enough to allow for changing gears when the motor was running without grinding. The last attempt ended in the clutch going to the floorboard and staying there when I pushed the clutch pedal down. It's like the pressure plate has given up the ghost as there is no pressure on the cross pedal (with the rubber tips) that releases the throw out bearing. Any ideas as to the cause will be greatly appreciated.

0

Comments

-

Sounds like the taper pin holding the yoke to the shaft is sheared, or the one holding the pedal hub to the shaft.0

-

Geoff, I'm not understanding what you mean by "the yoke to the shaft" as I'm unclear as to what shaft are you referring to. Is it the shaft that goes from the adjusting rod to the transmission?0

-

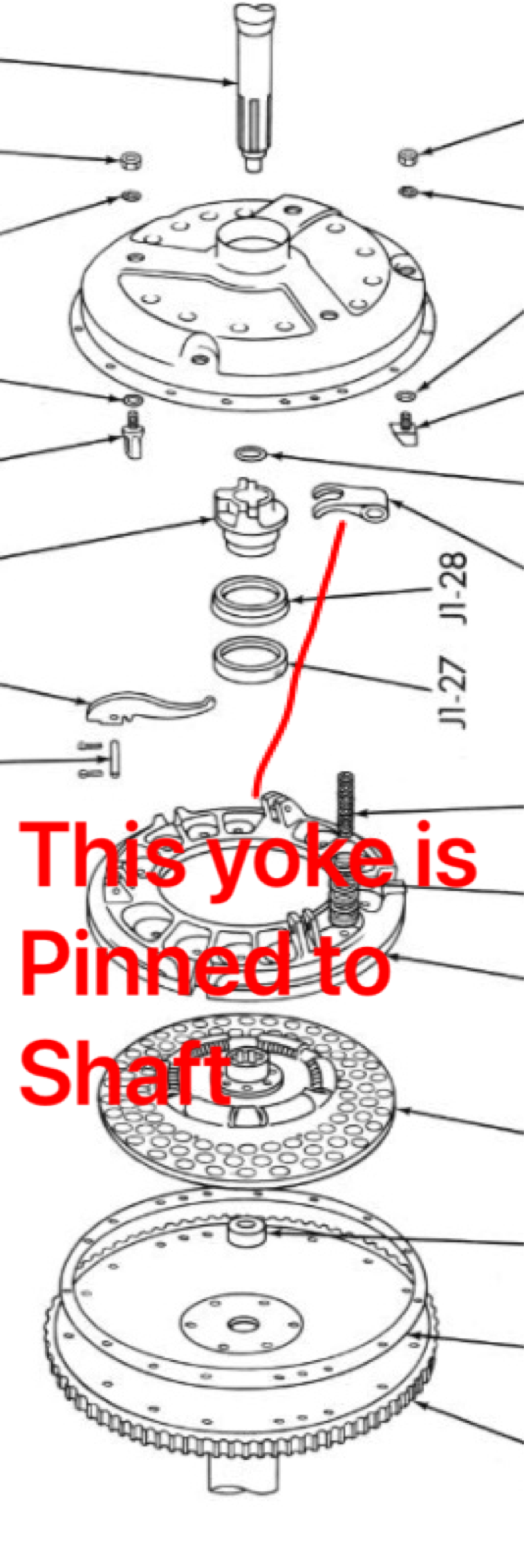

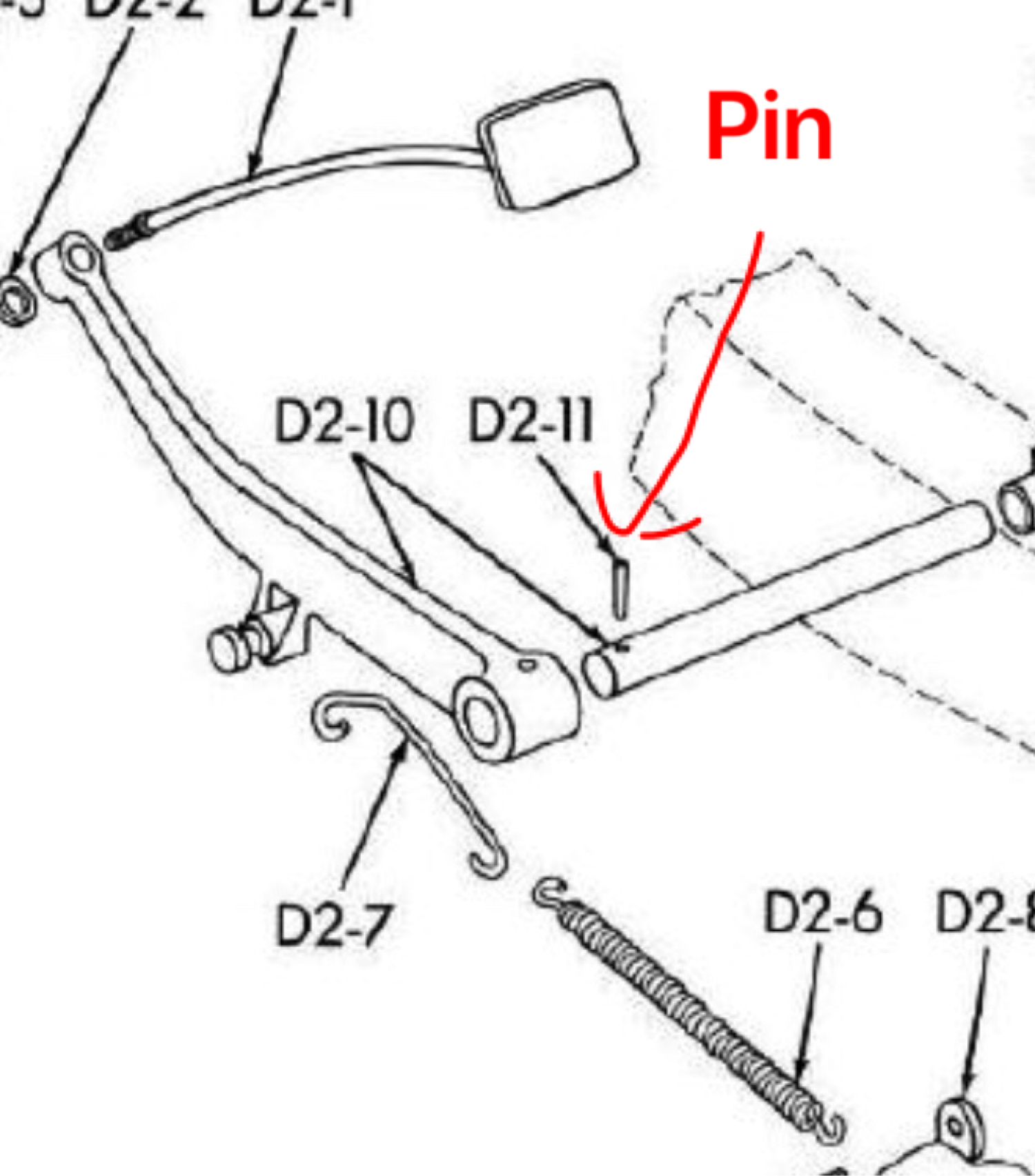

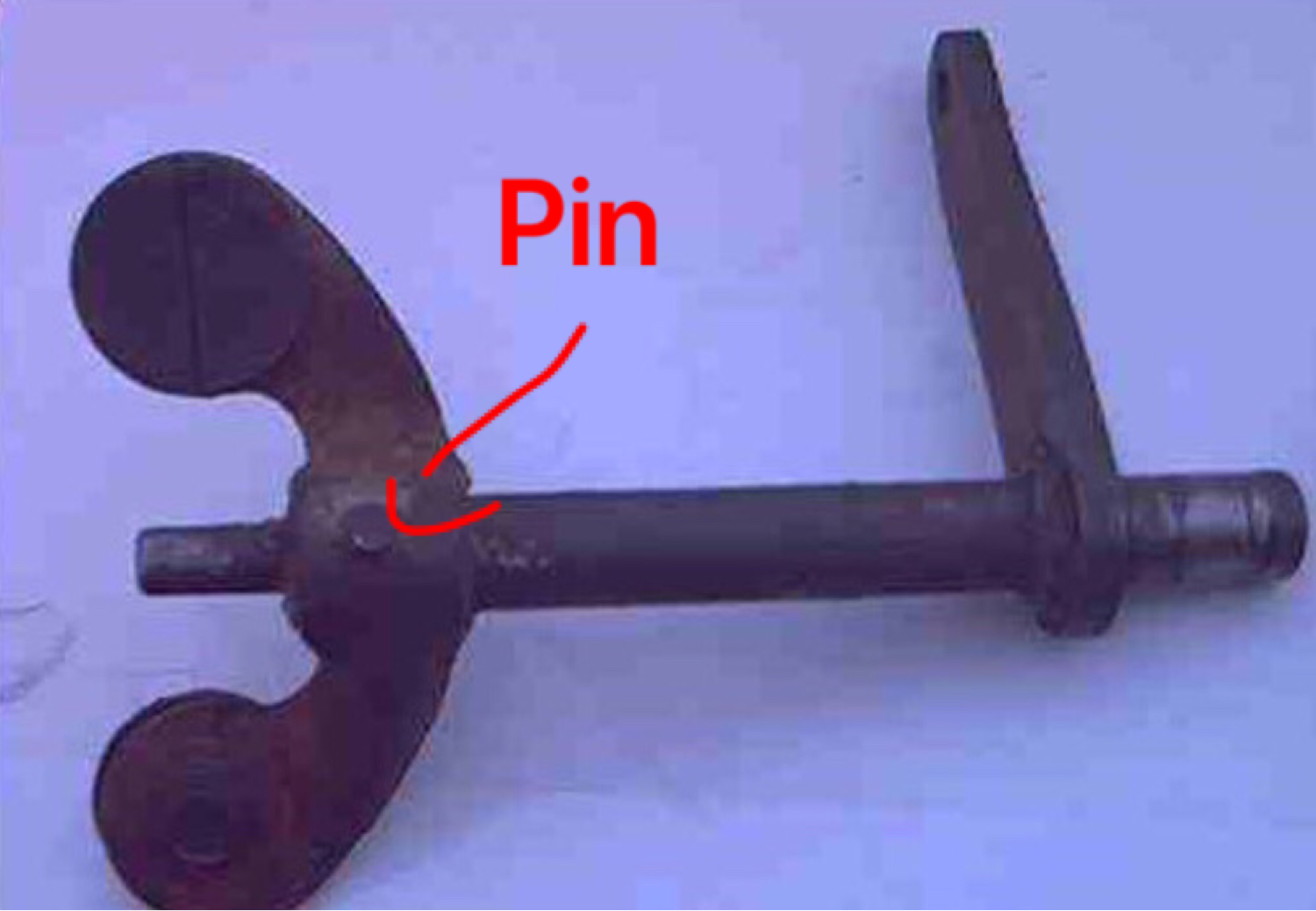

The pins Geoff is referring to connect the clutch actuating yokes (the 'ears' with the rubber tips or the ears it pushes on) to either the cross shaft from the pedal or the cross shaft within the bell housing.

The other possibility is that clutch throwout fingers within the bell housing have sheared their taper pins.

0 -

These are locations where pins are used to secure components to shafts used to release clutch.

0

0 -

Thank you Glowplug, as they say a picture is worth a thousand words. I had the pin shear off on my '39 H CC8 many years ago. Very difficult to replace, as you have to drill a hole in the housing to get access to the small end of the pin.

Geoff

0 -

Just another thought, if the spring is disconnected, broken or the frame anchor tab came out the pedal goes to the floor!0

-

Ken, if you are correct, what is the solution to this problem? (Two other people I talked to outside of this forum mentioned the "over centered" theory.)0

-

Get in and have a look. It should be staring you in the face.0

-

Assuming that one these pins has sheared off, is there an accepted method for repairing them?0

-

Yes, replace it!0

-

Funny Geoff. I had that coming... LOL.0

-

The external taper pins are #5 size, the two internal taper pins holding the throwout fingers to the cross shaft inside the bell housing are #4 size. As well as new taper pins you will also need a #5 and/or #4 taper reamer.

None of this taper pin replacement work is easy to do under the car, realistically its a parts on the bench job.

Full disclosure. Removing and replacing taper pins can be a PITA even when you have the parts on the bench.

Take a good look at all the pins in the system before reassembly.0 -

Sorry Jason, I couldn't resist. It's not so difficult replacing the one on the outer end, and from memory the finger assembly has two pins, so unlikely to be in there. On earlier models with the shorter shaft, if the pin shears holding the lever assembly then you have to drill a hole in the housing to be able to drive the broken pin out, as the large end is at the rear. You must have a good solid punch and a heavy hammer, and solid "energy sink" like a 5lb hammer head or anvil behind the assembly when you try and drive the pin out. Have fun.

Geoff

0 -

I took the transmission out and removed the pressure plate. The only thing that seems way out of whack is the throwout bearing is extremely lopsided. There are gouge marks on the surface of it that seem to have caused by the throwout fingers of the pressure plate. My guess is that this may be the source of my problem. I can't see any evidence that the taper pins are sheared.0

-

Photos?0

Categories

- 37K All Categories

- 116 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos