Broken instrument needle repair

Much to my dismay the aluminum needle on the fuel/0il gauge flew off and rested at the bottom of the instrument cluster just below the opening. Hemostats, needle nose pliers, tweezers and even powerful magnets failed to retrieve the renegade pointer!

Finally, a toothpick with a piece of masking tape did the job.

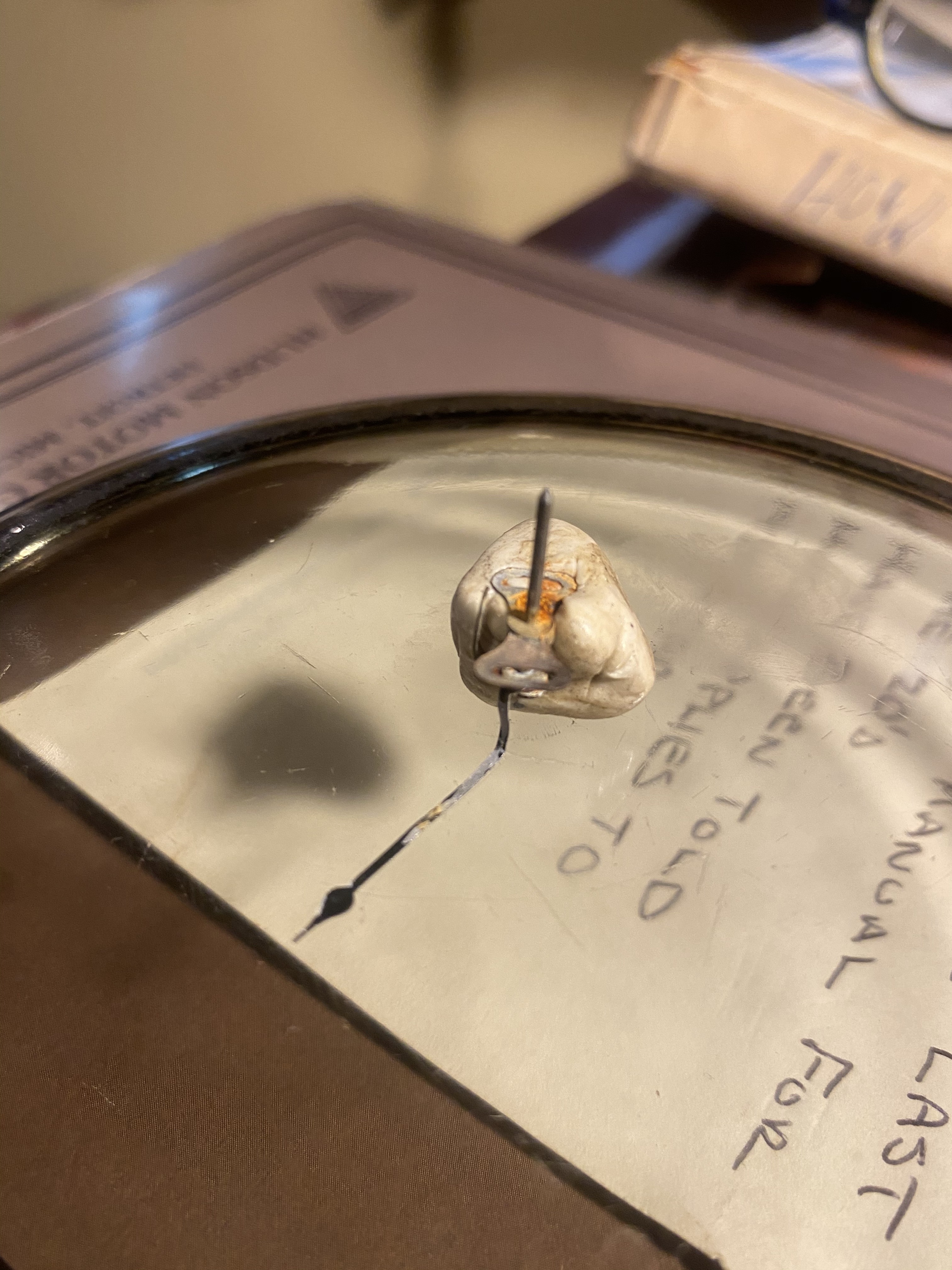

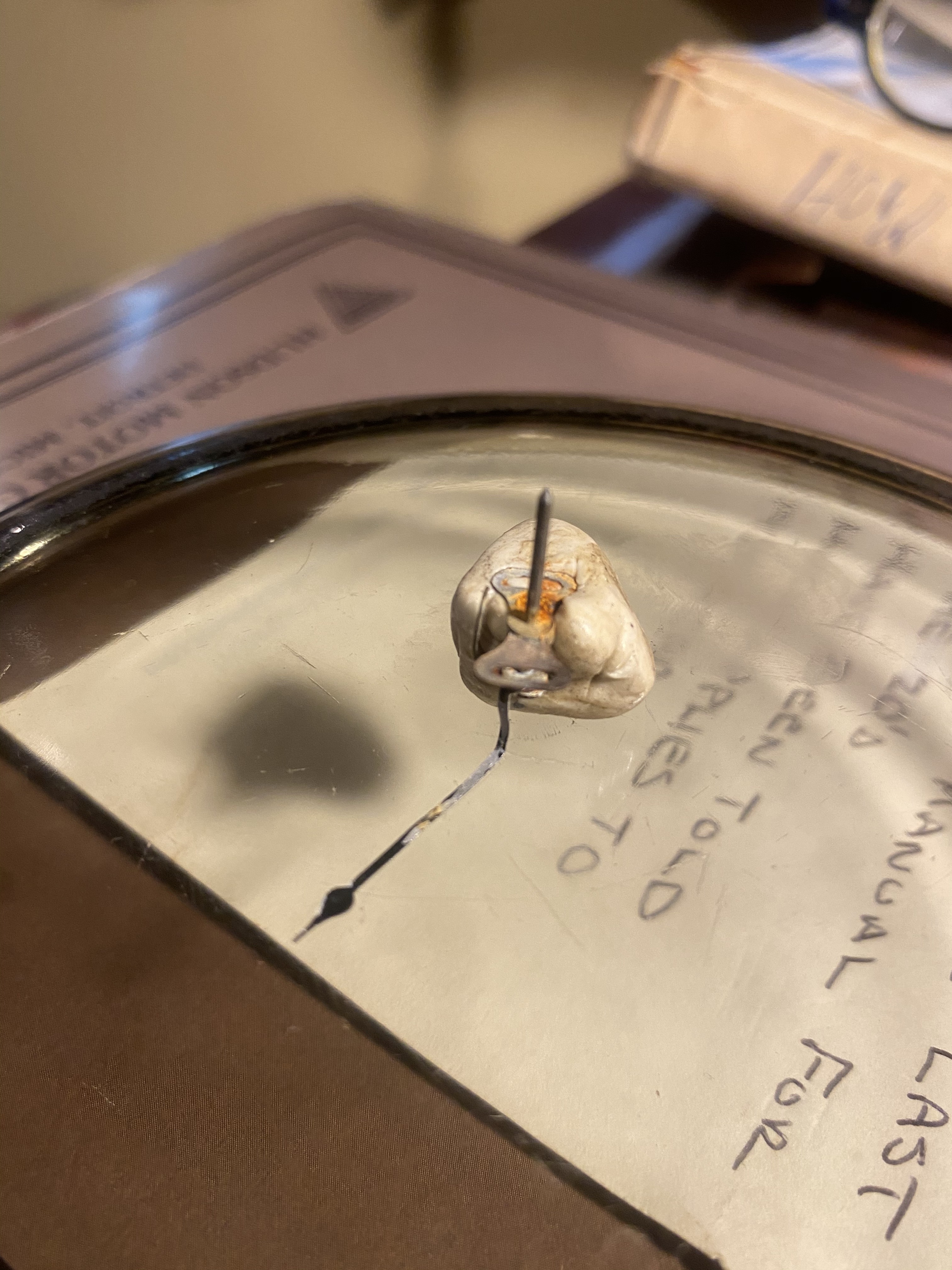

My hands just aren’t steady enough to set the needle in exactly the right place for 5 minutes while the epoxy cured so I grabbed a small piece of plumbers putty to secure the armature squarely to a piece of flat glass at exactly the correct heigh. Then with a fresh toothpick I place a tiny glob of epoxy to the original location where the needle sheared, marked with a fine point sharpie.

Finally, a toothpick with a piece of masking tape did the job.

My hands just aren’t steady enough to set the needle in exactly the right place for 5 minutes while the epoxy cured so I grabbed a small piece of plumbers putty to secure the armature squarely to a piece of flat glass at exactly the correct heigh. Then with a fresh toothpick I place a tiny glob of epoxy to the original location where the needle sheared, marked with a fine point sharpie.

Then I slid the needle into place and let it cure after which I applied another glob to the opposite side of the armature in a ham handed attempt to correct the weight imbalance by the weight of the repair. Finally I applied another fine layer of epoxy over the repair, just enough to reinforce it but not enough to interfere with it’s free movement.

Before carefully replacing the face of the gauge I added some wood glue to the cloth tape covering the coils which had come loose.

It’s now ready to go back into the cluster, good as new and I didn’t need to send it to a professional.

It’s now ready to go back into the cluster, good as new and I didn’t need to send it to a professional.

I heard that it is possible to repair temperature gauges that have lost their charge by sacrificing the capillary tube and bulb from a new one and soldering it in place while the majority of the tubing is kept below zero with ice and salt, although I am considering making the attempt with dry ice instead just because it’s colder and has an element of danger!

Now the most important gauge, oil pressure, is suspect because it has been disconnected and I imagine that it will probably need professional attention. Does anyone have any recommendations for a good instrument repairman?

Now the most important gauge, oil pressure, is suspect because it has been disconnected and I imagine that it will probably need professional attention. Does anyone have any recommendations for a good instrument repairman?

0

Comments

-

Thanks!

I noticed that when the engine is idling, the needle vibrates rapidly at empty. So I am going to ground out the sending unit wire so that it peg out at a full tank reading and stop shaking itself to death again until I clean, repair and fill the fuel tank.0 -

Thanks much!

Glad to have been a help!0

Categories

- 37K All Categories

- 115 Hudson 1916 - 1929

- 21 Upcoming Events

- 94 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 180 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 77 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos