Super Six 1947 engine oil leakage

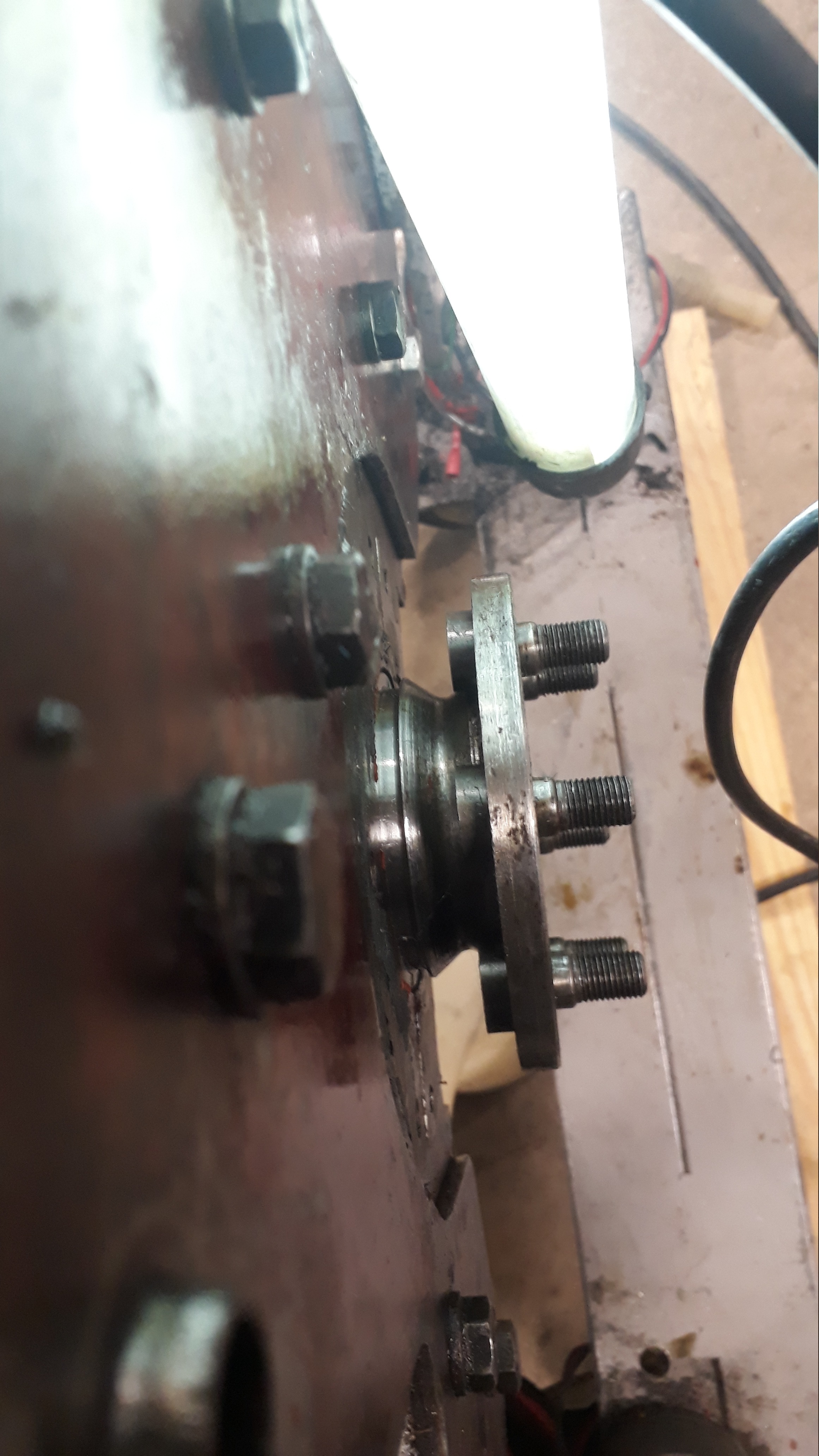

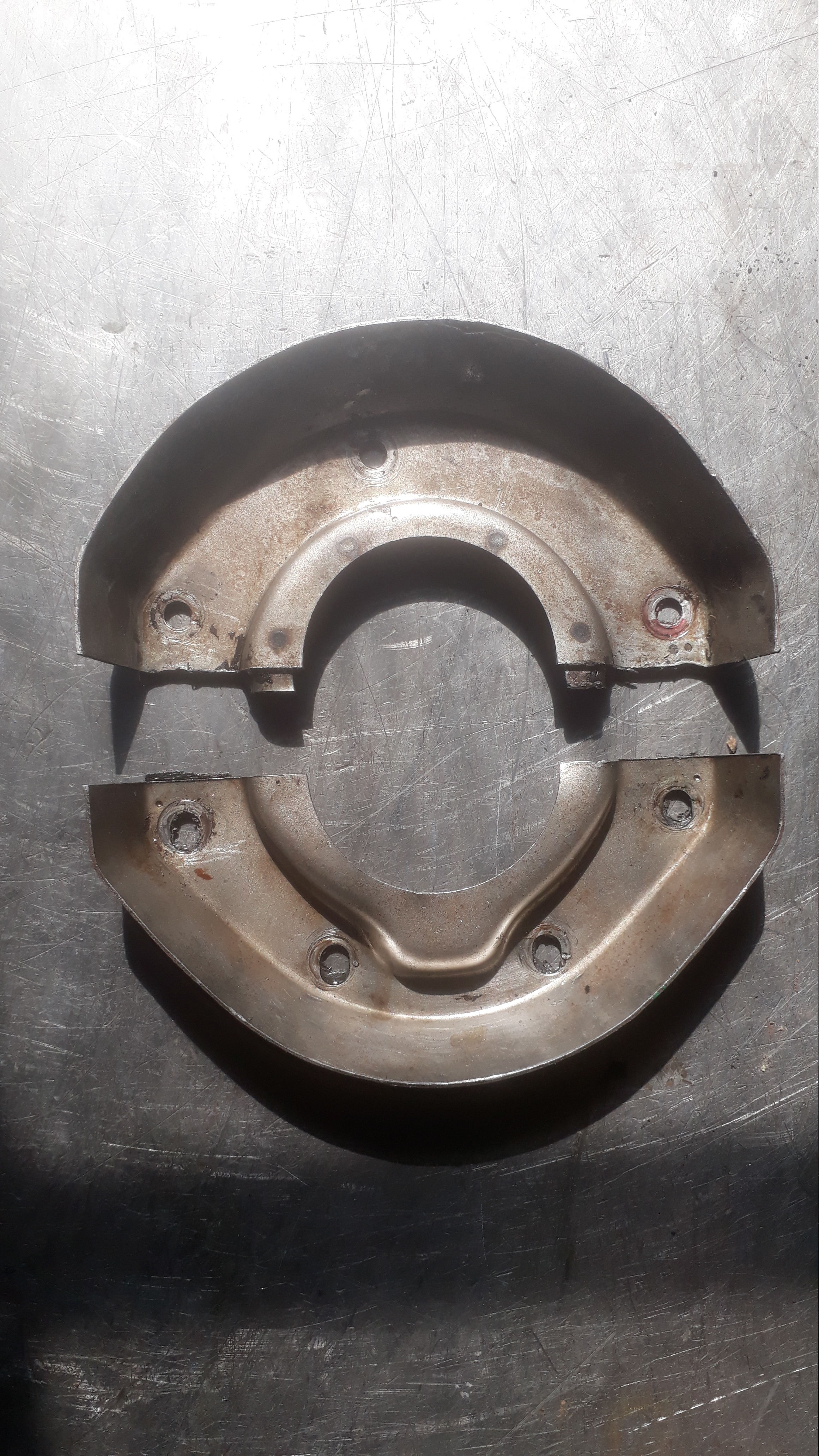

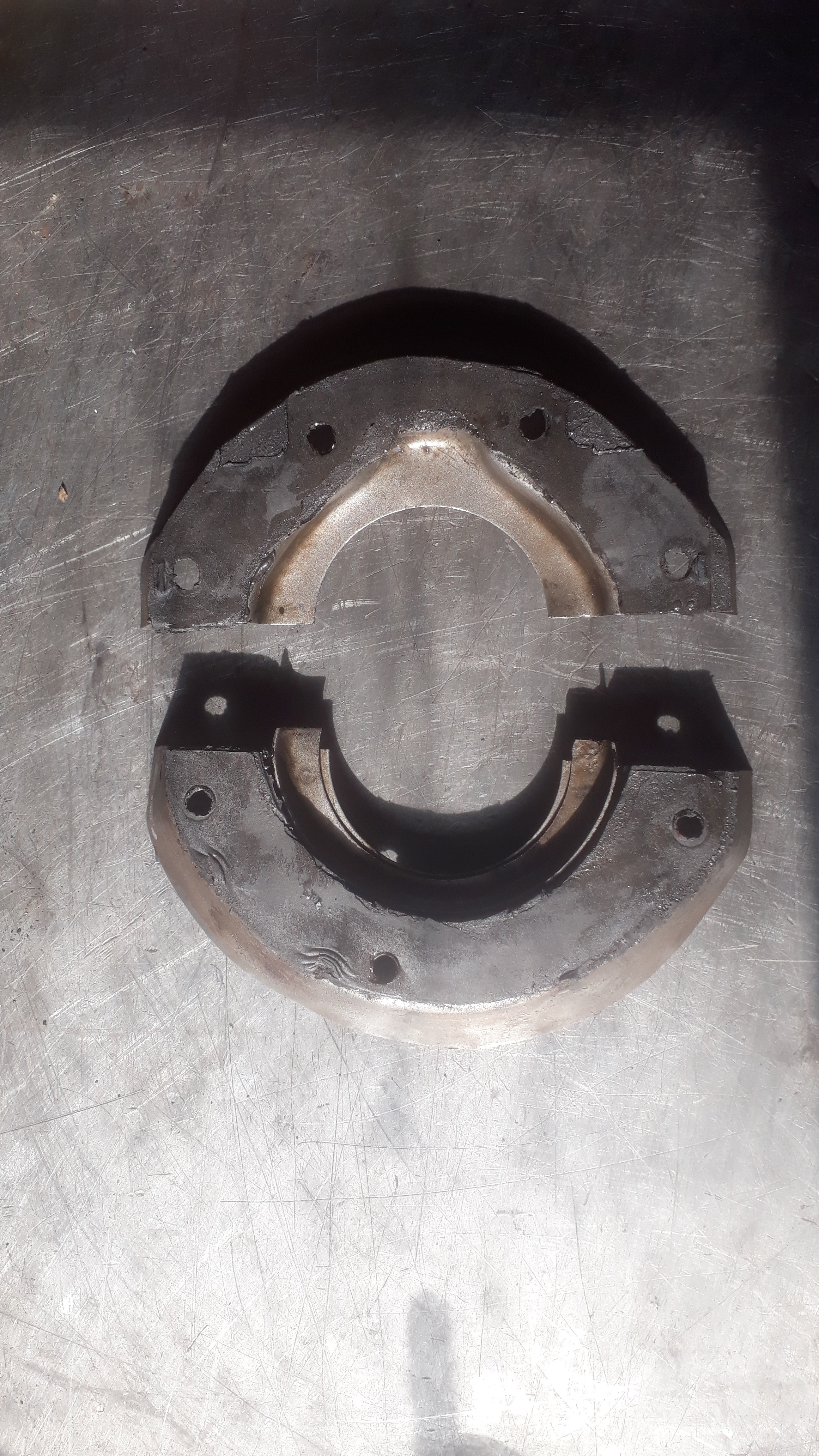

Could anyone enlighten me, how to properly install the rear oil seal (the rope) in a 1947 Hudson Super Six engine? I’m helping a veteran car owner to solve this problem. The engine is mounted separately, so it’s easy to test. The return pipe down to the oil pan has been checked, there is free float. The workshop manual shows a not so clear photo, where a cotton rope is installed form below, with a special tool (J-392 named). But I really don’t understand how a quite long rope may be wrapped around the crankshaft’s end like that. Thankfully the engine is ”free”, so I’ve tried to wrap the rope tight around by hand. However there is too much oil leakage when the engine is running, so there must be a better way to fix this. Or is there something better than this rope? I enclose some photos of the crankshaft end and the reatiner halves. If there is someone who could help, it would surely be appreciated.

Comments

-

Any oil that leaks out from between the crank and the white metal bearing will return to the sump via the two piece retainer (oil slinger). Use gasket sealant behind this retainer. If you use cotton rope or strands from a cotton rope, you have to pack it in the hole hard. An easier way is to clean the passage where the rope goes and use a suitable sealant in a hand operated gun. You will see the sealant flow all around and out the other side hole. Hope you understand this. Im sure others will add more.

0 -

Thank you for your advice, barrysweet52. It is a blessing that I'm able to run the engine separately. I want to be sure that there is no leakage before the engine is reassembled into the vechicle.0

-

There is no rear seal in these engines like the big 6s have. There is a slinger, a larger diameter place on the crankshaft that slings oil into the return tube. Just make sure the gasket between the oil pans is clear where the return goes through the pans.0

-

Ok, do you consider the cotton rope ("cotton wicking" as it is named in the manual) actually is unnecessary?

0 -

The wicking is to jam up each side of the bearing cap to seal off any leakage past the join. You use a blunt screwdriver or punch, and feed the wicking up into the hole and punch it home firmly, and keep doing so until it is level with the bottom surface. it is not wrapped around the crankshaft as you have envisaged. Barry has correctly outlined how the slinger and plate work, to direct the flow of oil back to the hole down into the sump.0

-

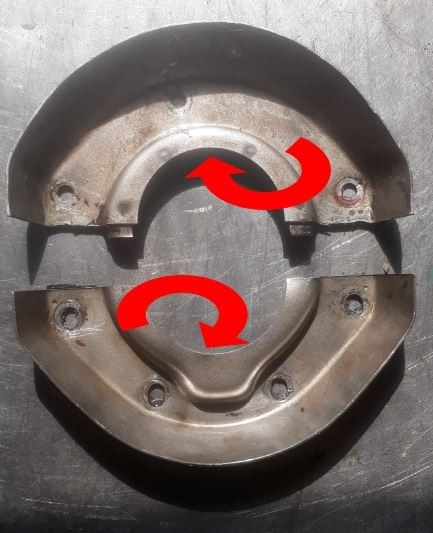

Ok, just to be sure I understand your good advices correctly. After mounting the oil slingers (with appropriate gaskets), the next thing to do is to stuff in the wicking, so as to speak, into the oil slingers as I have tried to "illustrate" in the enclosed photo.

0

0 -

If you put wicking in there, the oil can't drain back in to the pan. Those tins do the job all by themselves. The wicking goes in the groove on the outside of the main bearing cap. Between the cap and the block.0

-

You're looking for 6 holes, about 1/4 inch in diameter. 2 are horizontal in the front bearing cap, half in the cap and half in the block. They are blind, re they don't go all the way thru and they intersect the 2 vertical holes between the cap and the block. Pack the verticles first, then the horizontals. There are 2 in the rear bearing cap which split the cap and the block as well. Pack these full also. These will prevent leaks between the front and rear caps and the block.0

-

Those plates you illustrate are not slingers, they are the deflectors that guide the oil back into the drain hole. There is nothing in here. The holes Josh is talking about are drilled in between the block and the cap, and these are the ones you stuff the string into. And Josh has confused the issue slightly, as we are talking about the rear bearing cap. You will see a hole each side, from the bottom surface up. The purpose of the string in here is to stop the oil from leaking between the sides of the b earing cap and block.0

-

Well, if I have understood this correctly, to summarize this: the wicking is to be stuffed into the holes between the the rear bearing cap and the cylinder block, nowhere else. The deflectors are to be mounted with gaskets behind, on to the block and otherwise "allowed" to be free, given that they are not warped in any way. If this is the case, then the surplus oil pressured out from the main bearing will end up in the pipe that is connected to the oil pan. Perhaps I've got it right?0

-

Bingo!!!

0 -

Many thanks to you all, who have taken time and effort to answer. I will now run the engine again, with confidence (and also petrol...). Much obliged!0

-

learned how myself reading this thred.0

-

Also make sure the drain hole is not plugged when you seal the oil pan to the block. You’ll see it. Don’t use massive amounts of sealant either. I personally use Permatex #2 non-hardening sealant sparingly on the oil pan.0

-

I’m about to do the same thing to the engine that I just got. Great info!0

Categories

- 37K All Categories

- 117 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 610 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos