35 horn button

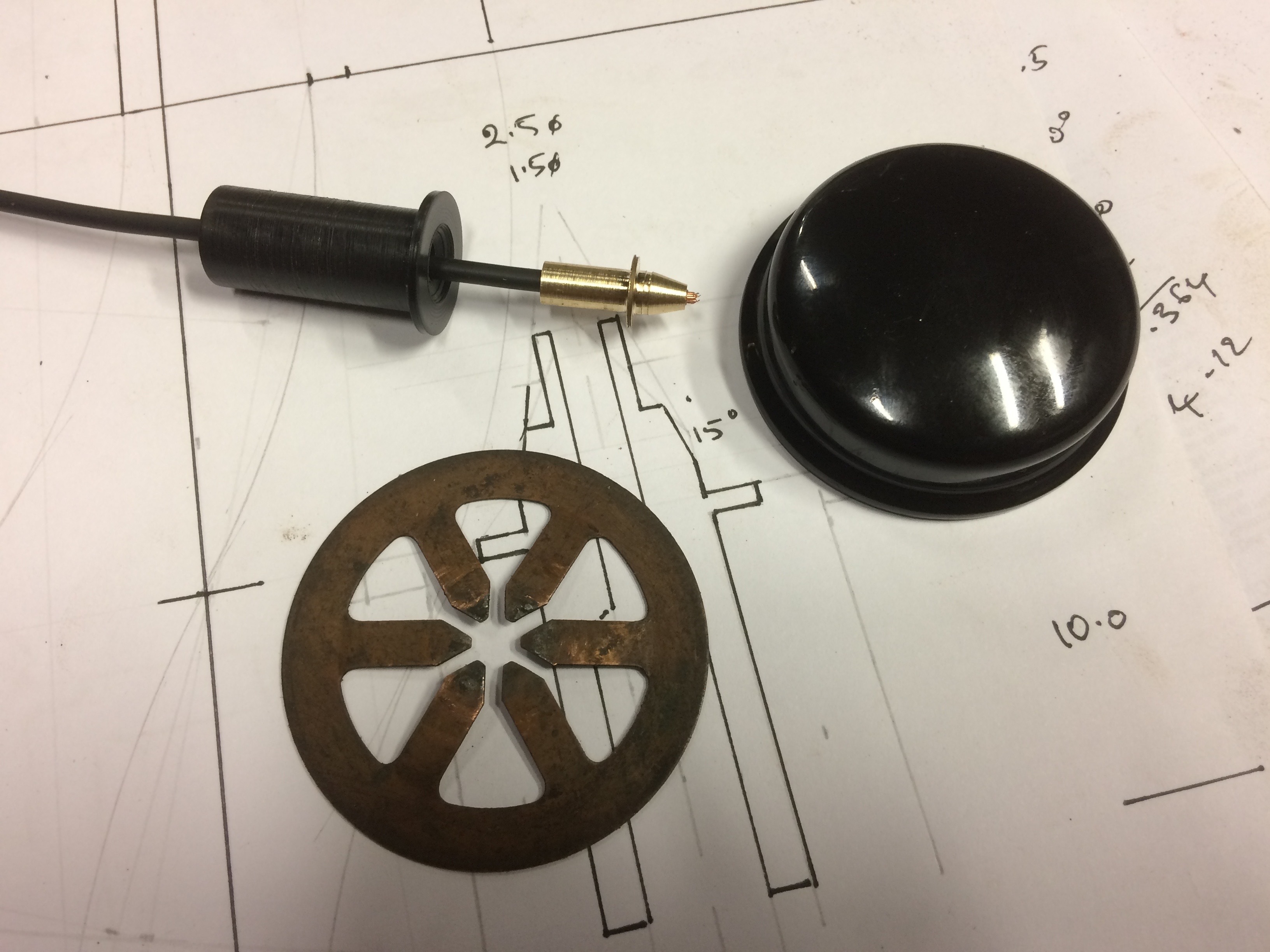

I have 4 out of what I think are 6 items that I need to have an operational horn button.

I'm missing an insulated plug that fits into the steering shaft, the plug holds the contact for the horn wire. Not too hard to make something suitable.

I'm also missing a spring (I think) that normally keeps the button lifted off the contact - bottom photo. If someone has access to one of those springs and can give the dimensions, number of coils, wire thickness I'll track one down or make something suitable. Thanks in advance.

I'm missing an insulated plug that fits into the steering shaft, the plug holds the contact for the horn wire. Not too hard to make something suitable.

I'm also missing a spring (I think) that normally keeps the button lifted off the contact - bottom photo. If someone has access to one of those springs and can give the dimensions, number of coils, wire thickness I'll track one down or make something suitable. Thanks in advance.

0

Comments

-

Bob.

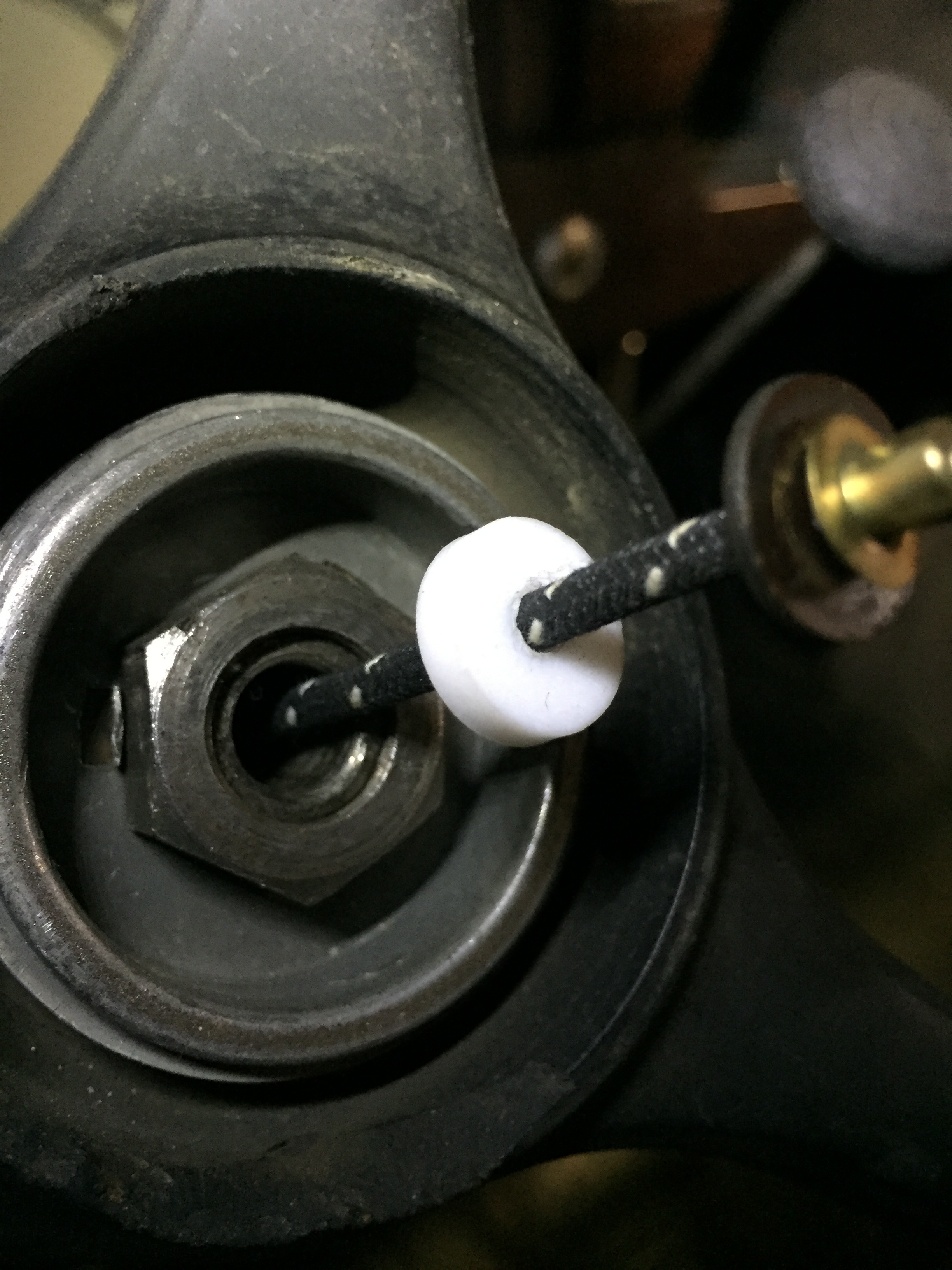

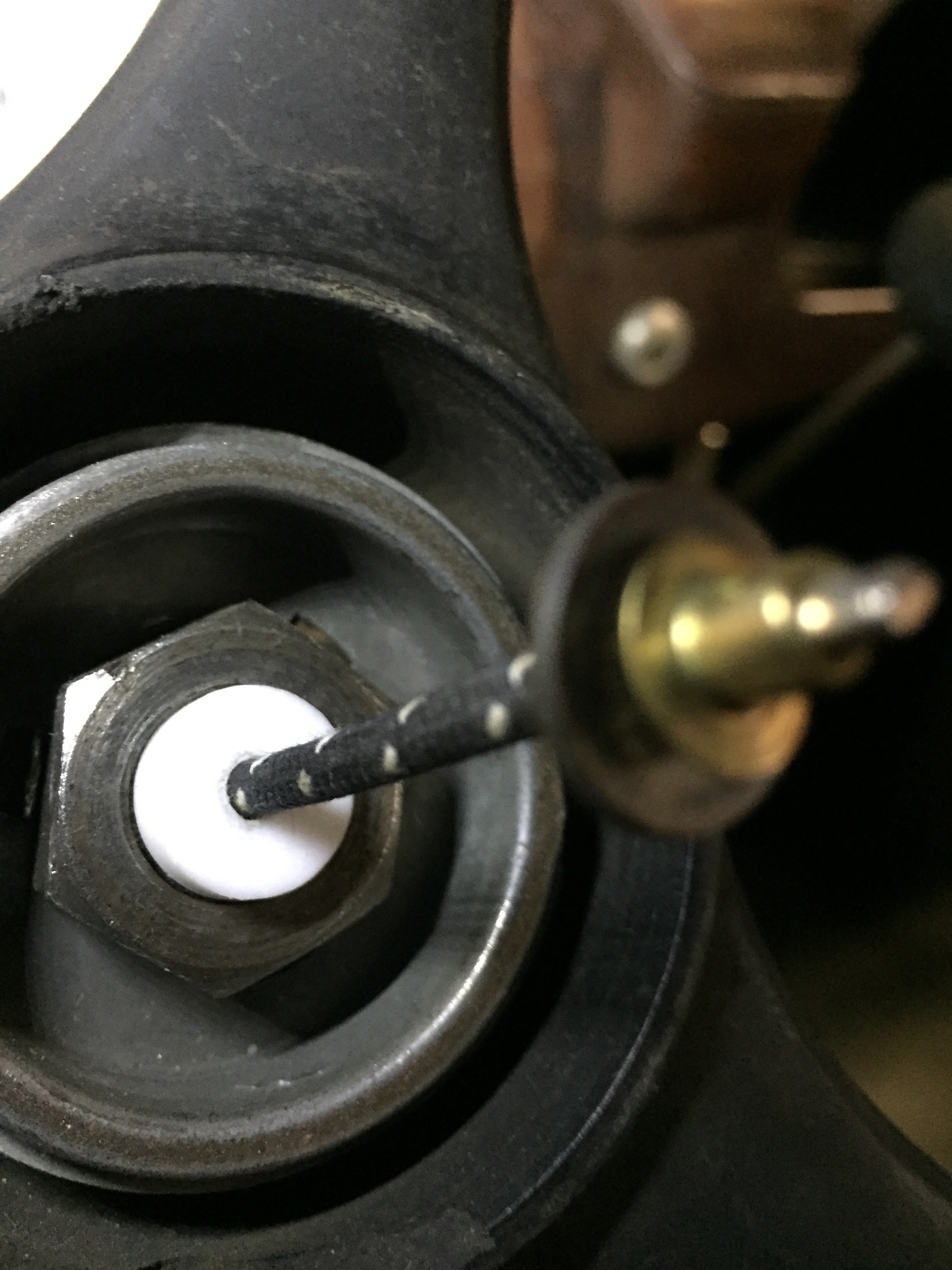

You appear to be missing three parts - wire coming up through the centre of the steering column (live wire), a non conductive washer (plastic or fibre) and a small "witches hat".

The wire is soldered to the witches hat which sits on top of the nut or just inside the rim of the nut. The non conductive washer isolates the live wire form earthing on the steering wheel column.

The sprung copper washer you have should not be level - it should be raised in the middle. This raised section rests on the witches hat and this keeps it from earthing - completing the circuit to make the horn work. After screwing the horn button to the steering wheel, the sprung copper does not connect to the earthed steering wheel until you press the horn button, and bingo, your horn circuit is complete and the horn should make a noise.

0 -

I had a problem with my horn going off intermittently. The pedals on the brass spring had flatten out. Turn a Teflon washers to shim it off the contact

0

0 -

https://julrichpackard.com/horn_instruments.htm Found this in my search for a new horn button contact spring. I don’t know if it’s the same size. Thought if I needed a new one I’d contact them and ask for dimensions

0 -

-

A solution for the witches hat - small copper washer and a big dollop of solder. It's only the rim of the hat/washer that needs to make contact with the horn button contact spring.0

-

Thanks guys, that is brilliant information.0

-

New insulating bush and witches hat. It occurs that the steering shaft, bush and witches hat will need to be a slip fit one to the other so the horn wire isn't constantly twisting with the steering wheel.

0

0 -

Very nice0

Categories

- 37K All Categories

- 116 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos