Priming an Oil Pump

Old Fogey UK

Expert Adviser

in HUDSON

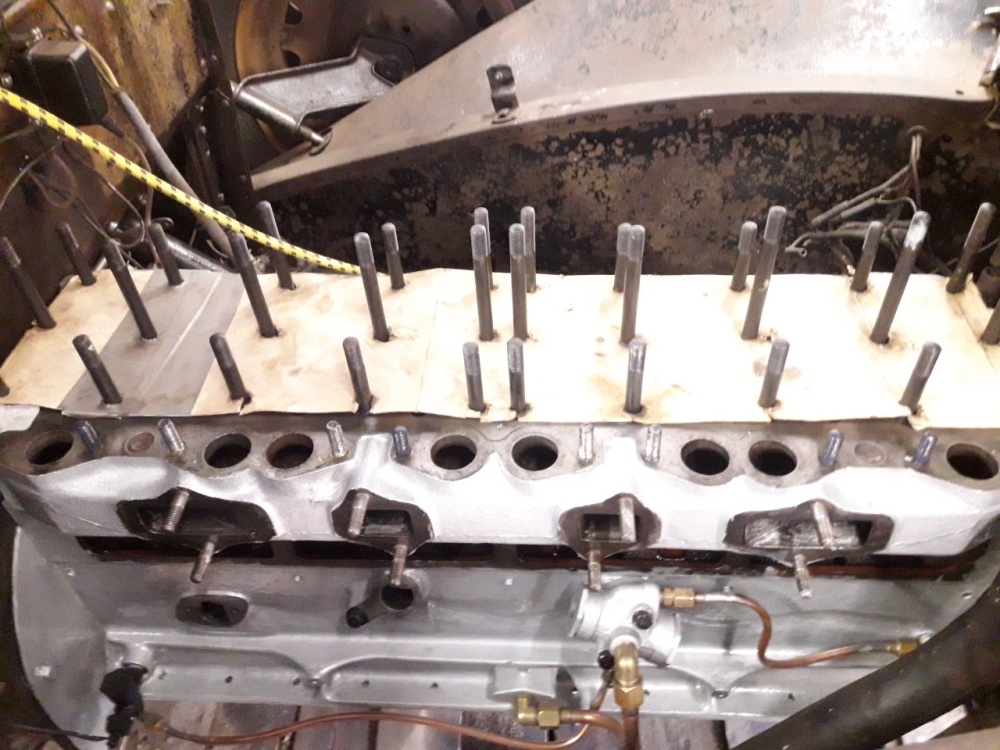

This coming week, I'll be reassembling my 254 engine after the honing and valve job.

I'll be using reassembly lube on the crank and con rods.

I remember reading in a WTN a long time ago that it was a good idea to fill the oil pump before starting an engine after the oil had been completely drained.

How do I do it, please ?

There's nothing in the manual about this procedure.

I'll be using reassembly lube on the crank and con rods.

I remember reading in a WTN a long time ago that it was a good idea to fill the oil pump before starting an engine after the oil had been completely drained.

How do I do it, please ?

There's nothing in the manual about this procedure.

0

Comments

-

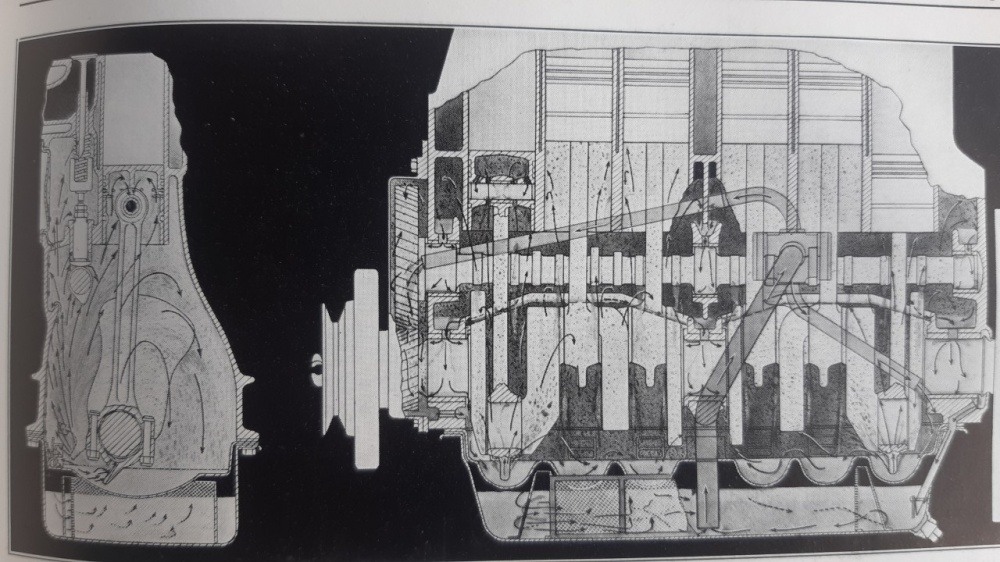

I cleaned out the oil pan on my 51 8 cyl. It is necessary to put a quart of oil in each trough of the upper pan. I put the two piece pan together and hung it under the with 4 long bolts same size as pan bolts. I used a funnel with a flexible hose to pour the oil in from the front and then raised the pan up in place. You can remove the side valve covers and pour it in through there. Do not start the engine without pouring oil into the trough or it will burn out the connecting rods.0

-

That's exactly the way I planned to do it.

The only difference is that I use a large syringe to fill the troughs.

It's a quart of oil in total that goes in the upper tray, I think.

It's the question of priming the oil pump that I was thinking about.0 -

You should check with Geoff on priming the pump.0

-

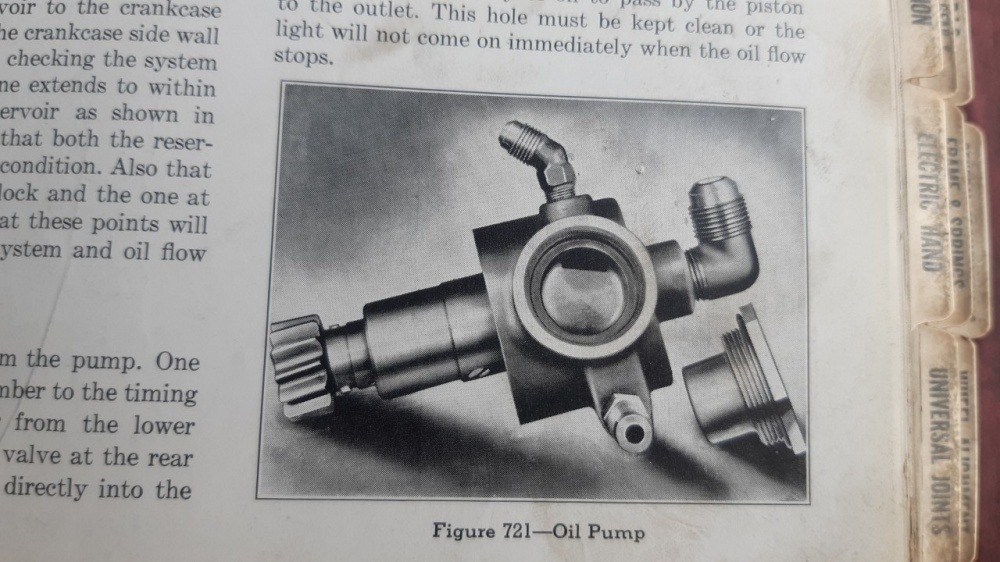

The splasher oil pump is a piston pump. The pistons are a very close fit in the bore and with minimal assembly oil the pump will produce enough suction to bring oil up from the bottom sump.

To check the system is working properly crank the engine over with the plugs out. Have one of the outlets disconnected to see that oil is indeed being pumped.

The weak link in the system is the joint between the sump(s) and the block, an air leak there is fatal.0 -

Simply put your oil can into the intake port and give it a few squirts. As Bob says, the pump will do the rest.0

-

There were no leaks previously on the oil pipes and neither they nor pump have been disturbed, so there should be no problem there.

Would filling the sump and troughs to the right level and cranking the engine over by hand a few times before I put the head back on circulate enough oil to avoid a problem ?

I will be reassembling the con rods with assembly oil first and will spray some engine oil around the crankshaft and camshaft before putting the sump back on.

Would that do it ?0 -

I will also use sealant on the sump gaskets, Bob.

I remember now where I read about priming the oil pump. It in Walt's Garage in an old WTN. I have looked for it but must have thrown out that particular issue.0 -

I'm going to do the same thing on mine. At the end of 1954

0 -

I've now swabbed the bores and all the internals with several pints of brake cleaner to get rid of any remaining honing dust , followed by drenching everything with WD40.

I'm now waiting for the ht bolts and locknuts to arrive so reassembly can be done.0 -

54coupe said:

That was a long time ago. You may want to think about doing it again. A lot of sludge could have built up in there over the last 67 years.JACK356 said:I'm going to do the same thing on mine. At the end of 195454coupe said:

That was a long time ago. You may want to think about doing it again. A lot of sludge could have built up in there over the last 67 years.JACK356 said:I'm going to do the same thing on mine. At the end of 1954

Very few km;c is in fine condition

0 -

For the start of the pump; I intend to try from the bottom with a large syringe and rotate the crank at the same time0

-

Oil pump and greasing schema

0 -

Do you also have the oil gauge in the pan?

0 -

Yes, but it doesn't work.JACK356 said:Do you also have the oil gauge in the pan?0 -

:'( :'(

At home as new

0 -

For the pan seal;given the number of years I was able to recover it intact.Like all the other joints too. Since Dale cooper never answered;I found someone who refabric them the same and even the breech joint and this in Belgique.Ca will avoid me from postage and customs that have become exorbitant

0 -

Jacky - if you became a member of the ROC, you could get all these parts from England - much less expensive than importing parts from the USA.JACK356 said:For the pan seal;given the number of years I was able to recover it intact.Like all the other joints too. Since Dale cooper never answered;I found someone who refabric them the same and even the breech joint and this in Belgique.Ca will avoid me from postage and customs that have become exorbitant

Look at

www.railton.org

0 -

Just be careful that you do not use too much sealant, particularly silicone, as if a bed of this gets loose and blocks a dipper or main bearing hole you are deep doo-doos. Loctite 515 flange sealant is a good one, as it only sets upon exclusion of air. A thin smear on both sides of the gasket is enough.0

-

Got it, Geoff.

Thank you.0 -

No loctite for me;mounting joints as originally;it worked over 80 years so when it leaked I would be dead..... Otherwise for the Roc; the fees is not better since Brexit; a cry....

0 -

Whichever way you look at it, old cars aren't an inexpensive hobby but they're still cheaper than golf or yachts - or at least that's what I tell Mrs Fogey !JACK356 said:No loctite for me;mounting joints as originally;it worked over 80 years so when it leaked I would be dead..... Otherwise for the Roc; the fees is not better since Brexit; a cry.... 0

0 -

Yes but I don't have that as a hobby; I also have the dinky toys; the track cars marklin sprint: the old garage emaillees and the old oil cans more than 300. Part of it here

0 -

Oil pump primed with a large syringe. From the bottom and I turned a few turns of the cranks.

0 -

I just changed the broken exhaust bolts in the block. I can no longer find in the book; the tightening of the cylinder head is how many KG? Nor the procedure. If anyone can help me;thank you

0 -

40 lbs.0

-

You could also spinn the motor over a few times on the starter with out the plugs prior to starting.Regards, Tom0

-

Hudson Eight sedan 34. 40 livre; 18KG Huge no?

0

Categories

- 37K All Categories

- 105 Hudson 1916 - 1929

- 19 Upcoming Events

- 91 Essex Super 6

- 28.6K HUDSON

- 559 "How To" - Skills, mechanical and other wise

- 993 Street Rods

- 150 American Motors

- 173 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 599 Vehicles

- 2.1K Parts & Pieces

- 77 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos