Do I Need to Replace my Clutch Fingers ?

Old Fogey UK

Expert Adviser

in HUDSON

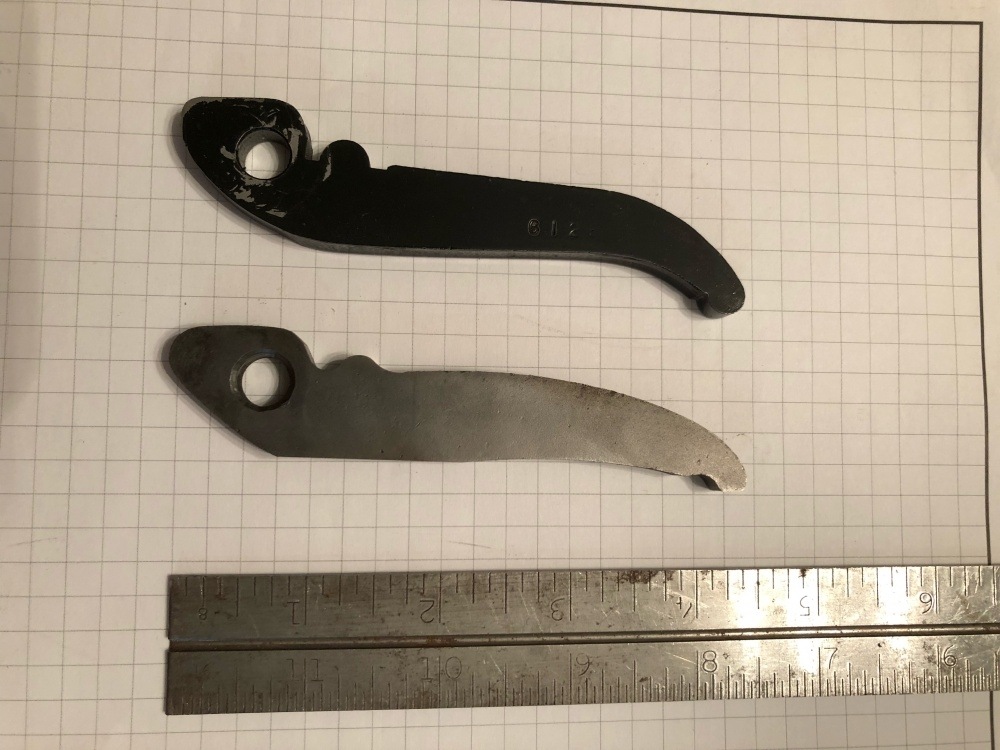

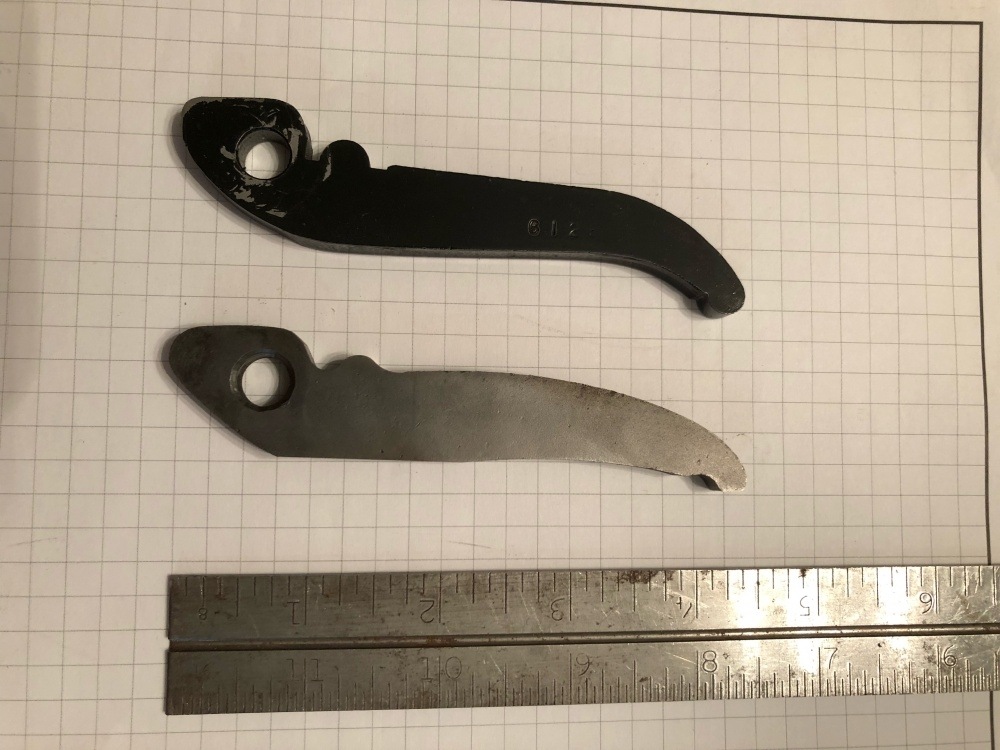

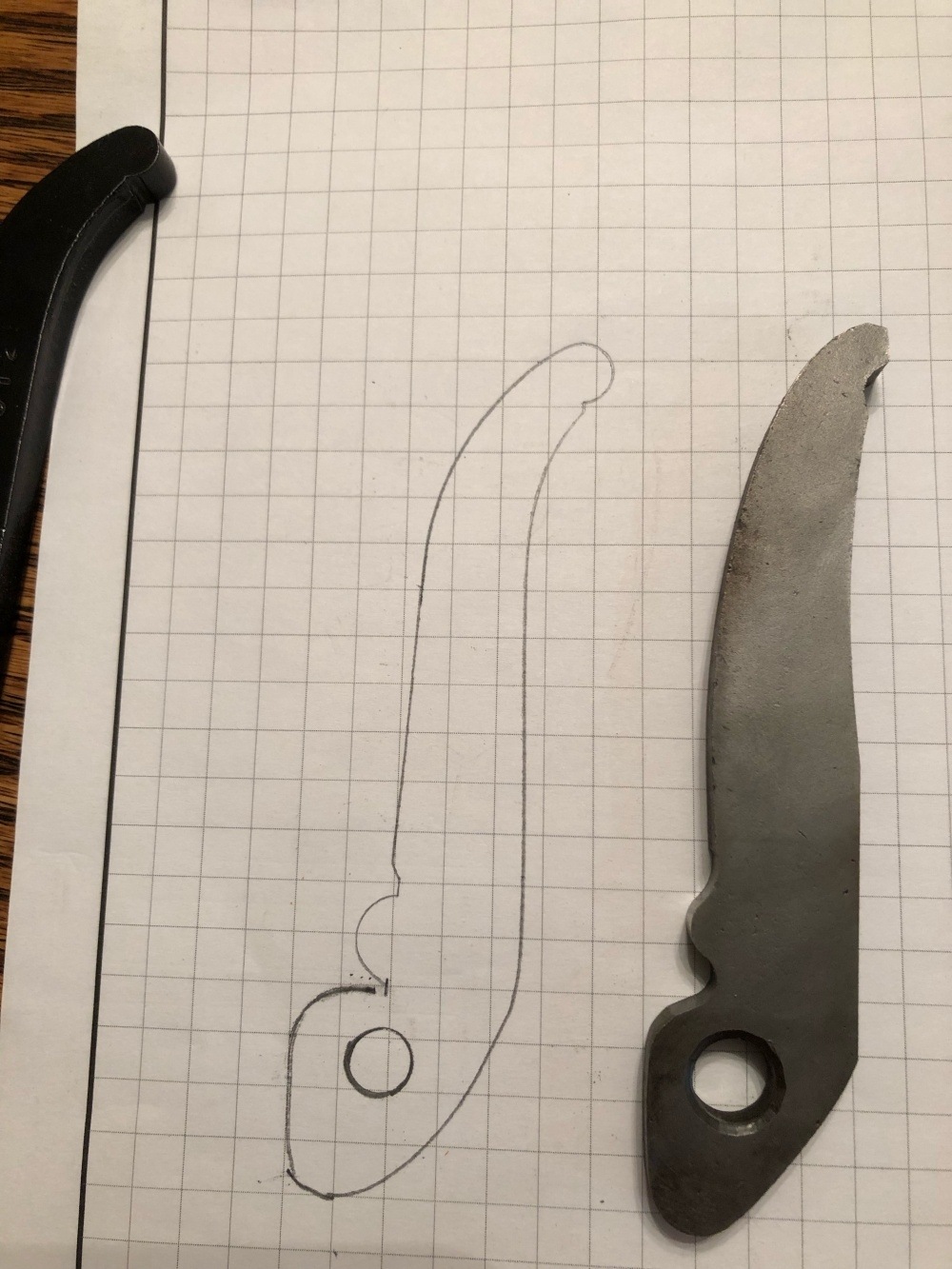

Should the tips of my clutch fingers look like this ?

Could they also be part of my gear shifting problem ?

Could they also be part of my gear shifting problem ?

0

Comments

-

They should not look like that, and should be replaced.0

-

Thanks, I suspected that !54coupe said:They should not look like that, and should be replaced.

How should they look ?

Are replacements available in the USA ?0 -

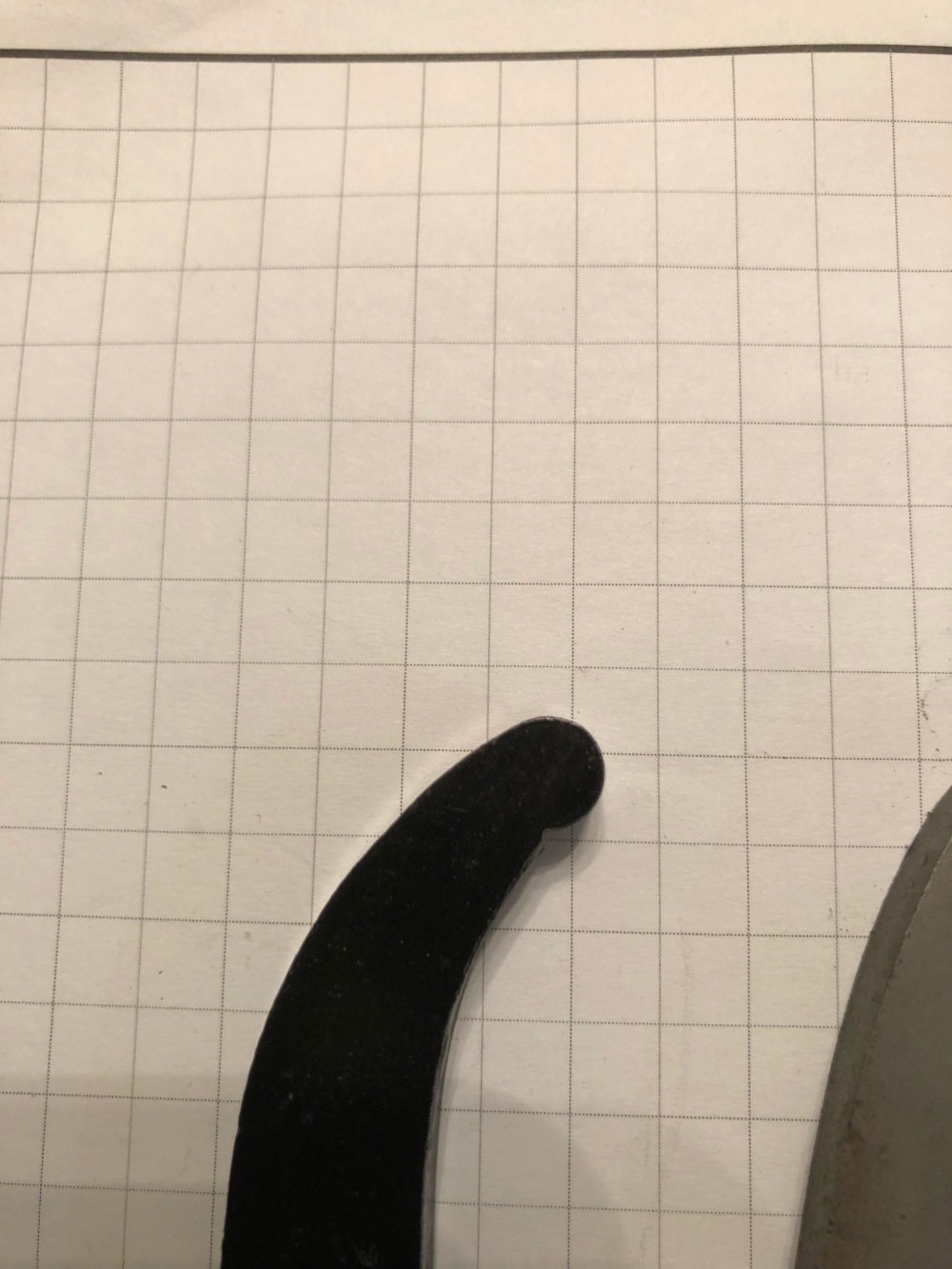

Doug Wildrick would be your best bet. The tips of them should have a radius. Probably about 4-5 mm radius. I don't have one nearby to measure.0

-

Thank you.54coupe said:Doug Wildrick would be your best bet. The tips of them should have a radius. Probably about 4-5 mm radius. I don't have one nearby to measure.

I’ll give him a try.

0 -

If you can't find new one ones, you can rebuild them with Hardcraft arc welding. Just a blob on the ends and re-grind them. Clamp the three together and grind all to the same rounded profile.0

-

Wildricks don't sell clutch fingers only complete assemblies that would be mega-expensive to ship to the UK.

Any other suggestions where I could get fingers, please ?0 -

Geoff’s suggestion for a repair method is an excellent idea.

regards, Tom0 -

Yes, I can get Stellite welding done locally.tigermoth said:Geoff’s suggestion for a repair method is an excellent idea.

regards, Tom

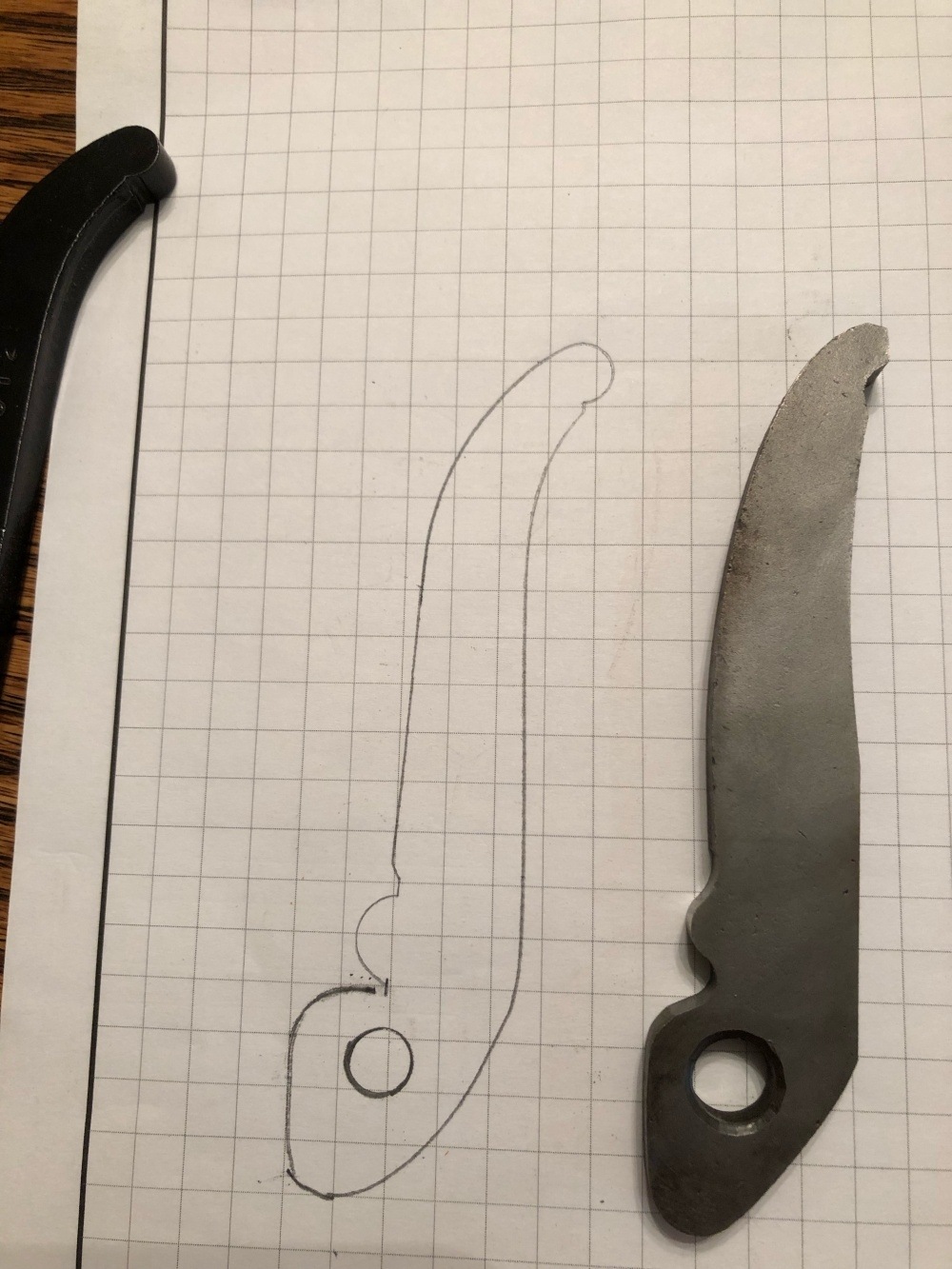

All I need is a traced outline of a perfect clutch finger to guide the amount of welding and grinding.

Please could someone oblige ?0 -

I will try looking at mine tonight and let you know.0

-

Using a machinist radius gage set the curvature end is 1/8 radius with the relief behind the nub as shown in your photos. There is a definite curve to the ends.0

-

A profile grinder (not by hand but like tool and cutter grinder) with an 1/8 inch profile ground into the wheel at a machine shop should be able to do it. On the other hand is there not a good set of fingers someone can send to UK ?0

-

Try Ron Fellows as well. He rebuilds clutches too.0

-

The Hudson Master Parts catalog 1948-54 shows different part numbers for the 9 and 10 inch clutch fingers - the Shop Manual makes note of setting finger height .005 or .010 - also the number of internal springs is different for 9 and 10 inch . As I recall you had a 10 inch plate and a 9 inch disc was mistakenly added for generous grief. You are going all 10 inch once parts are found. I found a good 9 inch pressure plate thinking the fingers all the same and had it on the hydraulic press but then checked the manual and no go. Gert0

-

Thank you all very much for the helpful advice, I'm really grateful.0

-

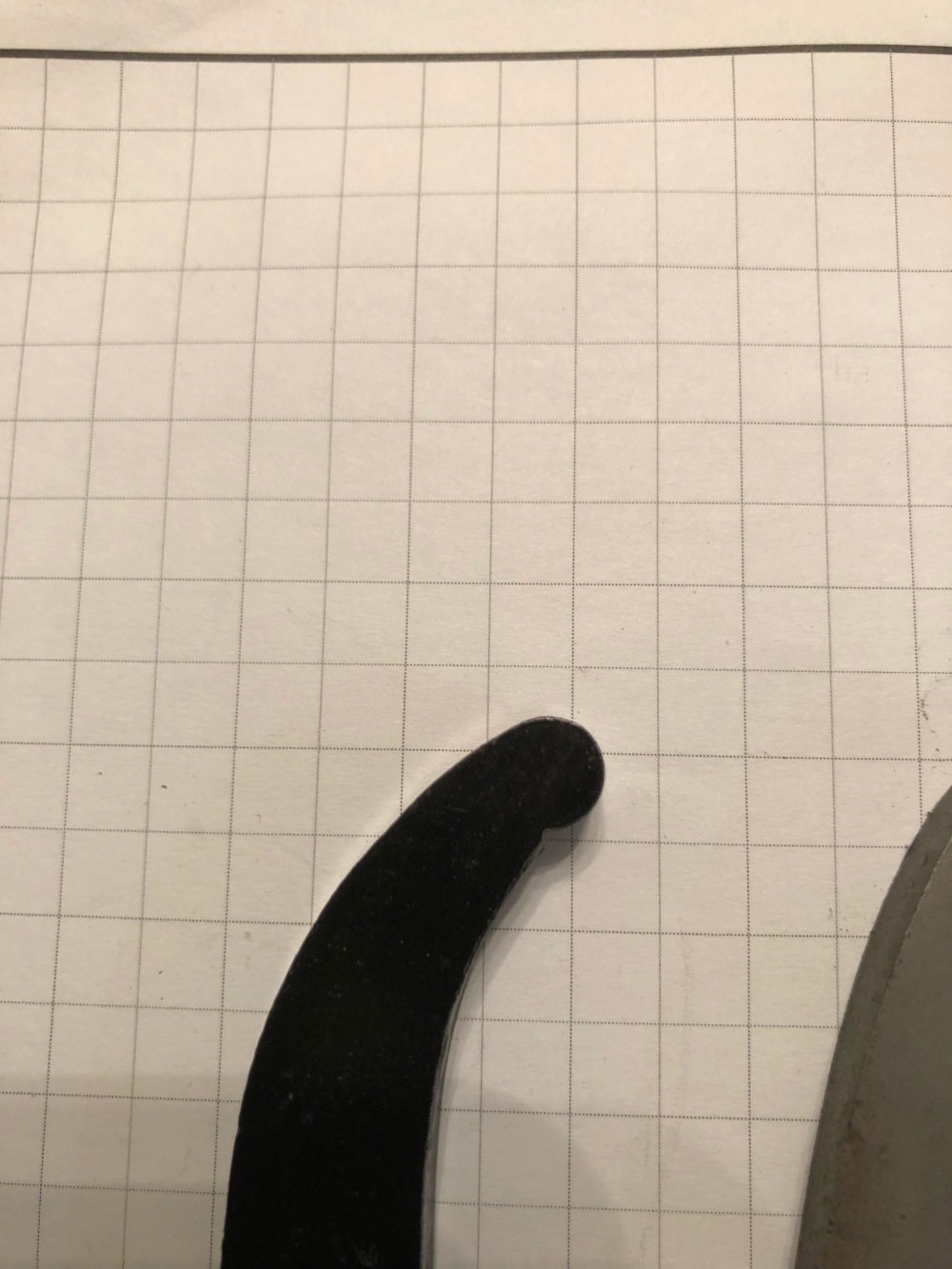

Don't know if this will help but here are a couple pix. The black one is good. the silver one is worn probably like yours. The grid blocks are 1/4" square.

0

0 -

Looks like someone with a wire EDM or water jet could knock a lot of these out in no time!0

-

That is brilliant !35Terra said:Don't know if this will help but here are a couple pix. The black one is good. the silver one is worn probably like yours. The grid blocks are 1/4" square.

Thank you x 1,000,000 !

We should be able to work with this.0

Categories

- 37K All Categories

- 104 Hudson 1916 - 1929

- 19 Upcoming Events

- 91 Essex Super 6

- 28.6K HUDSON

- 559 "How To" - Skills, mechanical and other wise

- 993 Street Rods

- 150 American Motors

- 173 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 599 Vehicles

- 2.1K Parts & Pieces

- 77 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos