Hornet 308 Hydramatic and Driveline questions

2 I do not have the floor pan hole to adjust the upper adjustment screws.

4. How does one get the car to quit leaking 2-3 quarts a month ?

thank you much ,

Blake

Merry Christmas! 🎄

Comments

-

Is this a dual-range Hydramatic?1. If I remember correctly, the 2-3 shift is always the trickiest to get right because one band is being clenched while the second one is being released. There is a procedure for throttle control linkage adjustment and internal band adjustment in the 1950-1952 Hydramatic procedure manual on the club library. The T.V. rod can be adjusted from under the hood. You make a couple passes up and down the road feeling for smooth, well-timed shifts. The bands must be adjusted from within the car, engine running, in-gear.I'm not a guru but I believe Gus Souza et. al. recommended starting with the T.V. rod for hard 2-3 shifts when I visited him. If you go all the way and do the bands, you will have to re-adjust the T.V. rod after. It's worth making sure your engine is tuned up before you do these adjustments. There is also a good diagnostic guide in the manual I specified.2. I thought all Hornets had the cut-out holes for accessing the trans dipstick and band adjustment screws. Is it covered with insulation or was the floor pan replaced?3. Engine oil or transmission fluid change?4. Your guess is as good as mine

Depends on where it's coming from. Merry Christmas!0

Depends on where it's coming from. Merry Christmas!0 -

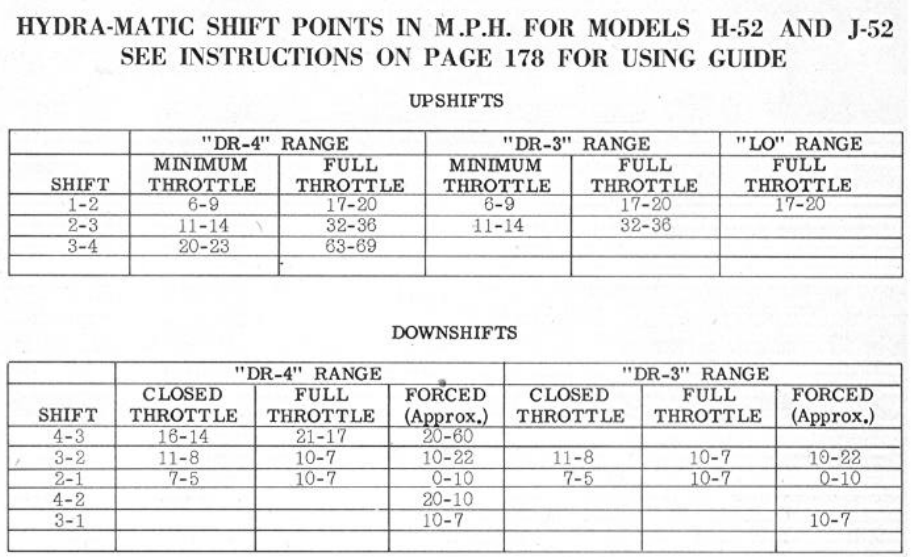

And here is a snippet from the manual on the recommended shift points for the H-52 model trans.

0

0 -

Hydramatic cars had a different transmission cover (removable floor board) than the stick shift cars. It should have a small access panel in the cover that can be removed for band adjustments.2. I thought all Hornets had the cut-out holes for accessing the trans dipstick and band adjustment screws. Is it covered with insulation or was the floor pan replaced?0 -

Very Good advice above. However, I would'nt consider adjusting the Bands until exhausting adjustment of the Throttle Pressure Rod to carb Linkage like Ate mentioned.

If drain Transmission fluid be sure to drain the Torus too by rotating flywheel to 6:00 to get at plug. If leaking motor oil, its usually the rear rope Seal and there is a modern neoprame replacement to roll in using an inexpensive Tool.0 -

@atc

thank you for the extensive response!So my tv rod it adjusted all the way down so the top lock nut is on the end of the rod. Do I readjust it on the trans with the rod down there?

2. Regarding replacement of parts I’m not blessed enough to have much history on this car other than it was as fast as one of the previous owners 70s Corvette

3 engine oil, I did the oil change already but I would like to get the pan off one of these days to clean it and seal it a little better.

4 I’ll have to give it a real good bath under there and keep tabs on the where about maybe of the leaks. (Thanks again!)

@54coupe I’m wondering if the trans cover has been replaced but at the same time it’s in the same shape as the pans so I’m not sure. I haven’t the little cover (as far as I know, only the master cyl cover)

@Ol racer I don’t know weather or not to level out the t.v rod down at the trans so I have some adjustment space.I’m gonna hate doing that , these transmissions are huge, I have a 65 Ford Falcon and I have worked on that trans 8 times and I can pull it out with one arm. This is gonna be a struggle !General question, should the the trans be drained and re filled , the cars been sitting for 20 years and it’s been driven 2000 miles since the long slumber

thanks again all

Merry Christmas 🎄

Blake0 -

Blake, I'm curious how close your shift points are to what ATC posted above. What you describe for rod adjustment position doesn't sound right at all. That may well be a major source of your problem. Refresh our memory. Was this Hornet originally Twin H, or was it converted by the previous owner. I'm wondering if you have some improvised linkage you're dealing with.0

-

@superwasp this car I believe originally came with twin h from the factory but when I got the car it had been converted to a 4bbl it has 7x modifications such as twin h, larger valves, hot flat top cam , headers .The rod adjustment is way off for sure, I will tinker with it when I get some spare time.

the numbers on that chart, I can’t get it to shift into 3rd until after 20mph no matter the throttle0 -

Resolution of the shifting concerns will take a comprehensive look into the factors that are related to the transmission shifting complaints. Hudson Hydramatic shift points are interrelated to the way the accelerator linkage is adjusted. The charts in the mechanical procedures manual are relative to the OEM equipped carburetor engines. The single bbl, double bbl, and twin H are all different mechanically. This requires separate but similar adjustments to achieve the proper shift sequences at right torque points.

The process depends fully on the placement of the TVI lever which sets the point at which the slide valve will allow fluid to the lock up the associated shift bands. The shift valve linkage rod is connected to the throttle linkage. After the throttle linkage is properly adjusted, the TVI linkage will allow the proper adjustment of the transmission linkage relative to that throttle linkage.

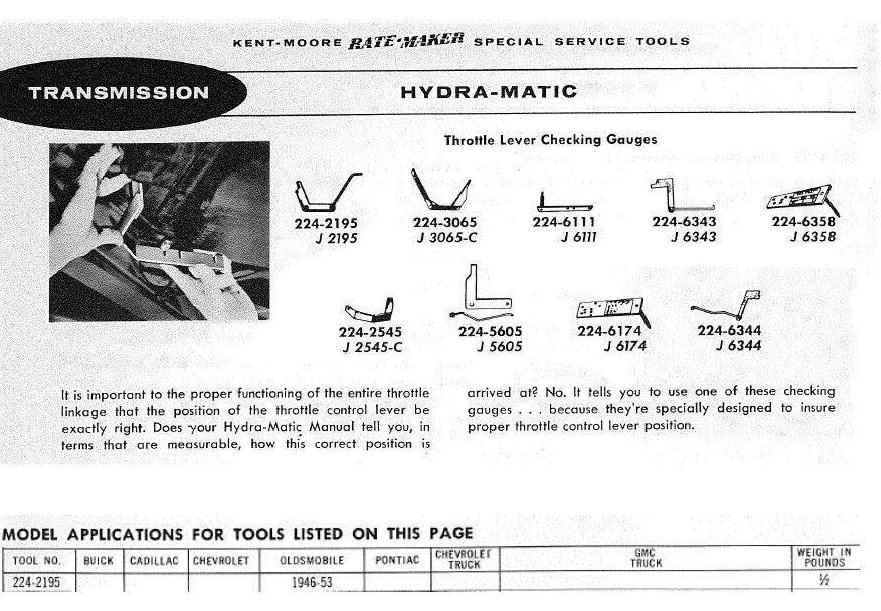

The process of adjustment begins by removing the linkage to the carburetor and adjusting the bell crank interlinks. The initial adjustment is made with the linkage locating pin (.125" drill bit) placed in the linkage locking hole located in the engine block. The throttle linkage is then adjusted to a place where the carburetor linkage rod will freely interface with the bell crank hole. The next step is to lock the adjusting nuts to maintain that alignment. The TVI gauge is then placed on the transmission case with the transmission throttle lever disconnected. The throttle lever link is examined and adjusted as with the carburetor so that the linkage matches the proper hole in the end of the TVI lever. Once adjusted the jam nuts are locked to maintain the mechanical alignment. After these adjustments start the engine and adjust the carburetor to the proper idle speed.

This procedure will work for any carburetor setup.

The manuals for the HYDRAMATIC are accessible on my website:

https://hudsonrestoration1948-54.com/

Go to the transmission page and the link is on the left side of the page.

One of the Hudson Specialty tool "TVI" tools

All of these comments are relevant only if the Transmission is properly serviced... ie right type and level of transmission fluid and that it is warmed through engine running.

Gus Suza was mentioned ... he told me... that the MAJORITY of Hydramatic problems he encountered were improperly serviced transmissions, followed by owners fiddling (adjusting) the linkage without knowing what the procedure was and then driving the car. A Hydramatic Transmission in a HUDSON is unforgiving... it requires proper Throttle Valve Lever adjustment and fluid service to work properly

Merry Christmas/// Ken Cates

0 -

ebay has a TVI tool available now

0 -

glowplug

do you have a link to that TVI tool on EBAY? I can't seem to find it.

J Lombard0 -

@Glowplug thank you much!As I was reading along I failed to comprehend something , so you pin the block detach the carbs and get the linkage aligned ,set the lock nuts and then what do you do with the carb rods since the linkage has been changed ?0

-

The carb linkages are adjusted to fit into the linkage.53NamedGeorge said:@Glowplug thank you much!As I was reading along I failed to comprehend something , so you pin the block detach the carbs and get the linkage aligned ,set the lock nuts and then what do you do with the carb rods since the linkage has been changed ?0

Categories

- 37K All Categories

- 116 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos