1946 straight 6 212 engine ring configuration

Hello Everyone,

I am starting to put my 212 back together.

Big question is what is the best/proper ring configuration? I have 6 pistons with pins in them, and a set of pinned rings. All was ok, until I got to groove #3 of 4. The pistons came out of the engine with an oil ring in groove 3. The new ring set I bought has an oil ring, a spring that goes in first, and 2 flat steel end caps that go along side the oil ring.

Any insights into the configuration I should use?

thanks!

dan

I am starting to put my 212 back together.

Big question is what is the best/proper ring configuration? I have 6 pistons with pins in them, and a set of pinned rings. All was ok, until I got to groove #3 of 4. The pistons came out of the engine with an oil ring in groove 3. The new ring set I bought has an oil ring, a spring that goes in first, and 2 flat steel end caps that go along side the oil ring.

Any insights into the configuration I should use?

thanks!

dan

0

Comments

-

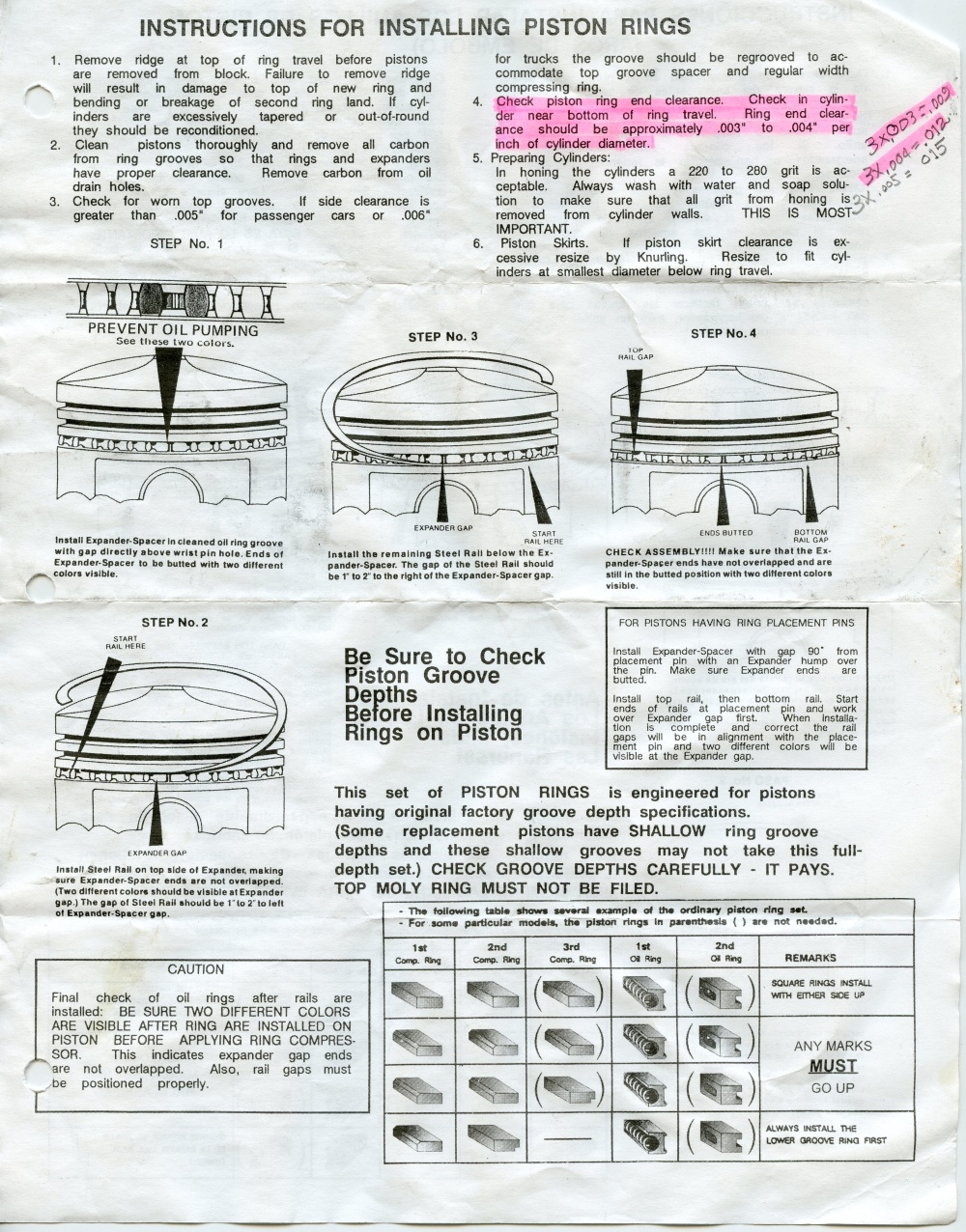

Here is some info that came with rings for my 6 212.

Hope this helps.

Ivan L.

0 -

Best way to get the rings in the holes is to grind a hose clamp on one side so it's nearly flat, then compress the lower oil ring and get it in the bore. Make sure you hold the compressors against the pins when you tighten them so you don't snap the ends of the rings off. Since the lower ring is 1/3 of a rev off you can't do that with all 4 rings at once. Then use the ring compressor for the top 3 rings.0

Categories

- 37K All Categories

- 116 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos