Super Six 212 tuning, acceleration issues

tylerwatts

Member

in HUDSON

Hi folks,

I'm hoping some of you who have more experience with Hudson sixes can help me get my '47 Super Six running just right.

When I brought the car home and got it running several weeks ago, I noticed that the vacuum advance was not doing anything (i.e. it's shot) and that I was missing the pipe running from the "stove" on the exhaust manifold to the auto choke. The choke heat pipe was an easy job w/ 1/4" copper tube. The vacuum advance has been trickier. Since replacements appear to be unavailable, and I've learned the hard way that NOS vacuum chambers are unreliable, I decided to adapt a Chevy stovebolt 6 unit, of which I have plenty. I also gave the 2-barrel stock carb a quick rebuild.

Now I've got the engine running pretty smoothly. I went ahead and set the timing to maximum vacuum using the vacuum port on the manifold that runs the wipers (let me know your thoughts on that timing method); I peaked at about 18" of vacuum and had rotated the distributor probably 3/4 of the way through the "quadrant" where the arm from the vac advance canister attaches to the distributor.

On my road test, I had a pretty bad stumble or hesitation when accelerating under a load (2nd & 3rd gear). It seems that if I keep the gas pedal down, the stumble resolves once the car gains some speed and then I'm cruising with more power. These symptoms are suggesting to me one of two possible troubles:

1. timing advance not functioning properly

2. carb accelerator pump malfunction (or related trouble... maybe the vacuum-based metering adjustment inside the carb?)

My adapted vacuum advance unit might be a bit wobbly--I need to make some improvements to the way it's set up. I'm wondering if it's not pulling as much as a stock unit would (i.e. shorter total travel) and how much difference that would make.

Please do chime in! I'm eager to get this car running just right so I can drive it around, especially now that the weather is finally nice in northern Michigan!

I'm hoping some of you who have more experience with Hudson sixes can help me get my '47 Super Six running just right.

When I brought the car home and got it running several weeks ago, I noticed that the vacuum advance was not doing anything (i.e. it's shot) and that I was missing the pipe running from the "stove" on the exhaust manifold to the auto choke. The choke heat pipe was an easy job w/ 1/4" copper tube. The vacuum advance has been trickier. Since replacements appear to be unavailable, and I've learned the hard way that NOS vacuum chambers are unreliable, I decided to adapt a Chevy stovebolt 6 unit, of which I have plenty. I also gave the 2-barrel stock carb a quick rebuild.

Now I've got the engine running pretty smoothly. I went ahead and set the timing to maximum vacuum using the vacuum port on the manifold that runs the wipers (let me know your thoughts on that timing method); I peaked at about 18" of vacuum and had rotated the distributor probably 3/4 of the way through the "quadrant" where the arm from the vac advance canister attaches to the distributor.

On my road test, I had a pretty bad stumble or hesitation when accelerating under a load (2nd & 3rd gear). It seems that if I keep the gas pedal down, the stumble resolves once the car gains some speed and then I'm cruising with more power. These symptoms are suggesting to me one of two possible troubles:

1. timing advance not functioning properly

2. carb accelerator pump malfunction (or related trouble... maybe the vacuum-based metering adjustment inside the carb?)

My adapted vacuum advance unit might be a bit wobbly--I need to make some improvements to the way it's set up. I'm wondering if it's not pulling as much as a stock unit would (i.e. shorter total travel) and how much difference that would make.

Please do chime in! I'm eager to get this car running just right so I can drive it around, especially now that the weather is finally nice in northern Michigan!

0

Comments

-

Replacements are never "unavailable" for a Hudson. You just have to sniff around a bit. https://www.ebay.com/itm/143966244436 . Also, if you haven't made friends amongst other '47 212 owners, do so. You'd be surprised how "available" things can be when you ask fellow owners. (In the absence of the real thing, there may be a decent substitute that people are using.)

I tried the vacuum method of timing once, and it never worked for me. I kept getting knocking in the engine until I eased off the settings a bit. I just set it via the flywheel markings and a timing light, and was happy with what I got.0 -

Hi Jon,

When I say "unavailable," I'm referring specifically to new parts. I did pick up a NOS part from a forum member here, but unfortunately the flexible membrane was torn. I'm aware of the NOS/ NORS parts... I'm just a bit worried about risking money on items such as this, where age and dry rot can make them inoperable. I might have to pull the trigger, though, to make sure I'm getting just the right amount of advance--thanks for sharing the link!

I'm thinking I have too much advance using the max vacuum method. I'm going to go back tomorrow and try it with the timing light.0 -

Sounds like you have too much advance, as it’s best to back off a pound or so from the max. vacuum reading at idle. If you’re at sea level and your engine is stock and in good condition 18lbs sounds a bit low I would have thought.0

-

A few years ago I heard of a business in New Zealand that was reconditioning the advance units. I dont have any more info on this. A business opportunity perhaps.0

-

I have a 212 in my 39 Hudson 6 but I do not have the vacuum advance system on it. But I agree with John B as I set the timing to the flywheel marks as I tried to set it to Max vacuum once I have a vacuum gauge and got the stumbling that you speak of and the hiighergears.0

-

I prefer the vacuum timing method, as you did it, however I back it off one and a half points from max. vacuum... so in your case, 16.50

-

18" sounds too low assuming you're not in the mountains with thin air, I would investigate the condition of the engine, compression, timing, mixture. Once that checks out, use the wiper port as you did for the vacuum gauge and back it off by 1" off the maximum reading then road-test (this depends on your fuel too). Then double-check that with a timing light against the timing marks on the flywheel just to see how much advance you ended up with and to ensure you're not way out with what is expected.This is a good detailed article on what to do: https://automotivemileposts.com/garage/v2n8.html

0 -

Terraplane,

Thanks for that link--their timing guide and vacuum reading diagnosis page is helpful! So I basically did your procedure earlier today: found max vacuum (again about 18", maybe a tad more), backed it off 1" to 2", then checked with timing light. I was on the 4th hash of advance (the farthest advance), so that didn't seem too crazy. Engine sounded very smooth at idle, but as I manually opened the throttle (using the linkage), it did the same stumble/ hesitate once it got closer to WOT. I'm starting to think this might be a fuel delivery issue? It's got a stock-style mechanical pump, which I think might not be delivering enough fuel consistently at higher engine RPM. I picked up an inexpensive 6v electric pump, which I plan on setting up. Another thing I'm wondering about is maybe a clogged up exhaust system? From what I've read, if the clog were partial, it wouldn't necessarily register until higher RPM/ more airflow through the system.

I'm also going to go through the ignition just to ensure that everything is in tip top shape. Anyone know where I can get points and a distributor cap for a 212?

Thanks for all the feedback!0 -

Geoff Clark would be able to give some good pointers on carb issues, as there are quite a number of things to check, ie what you have mentioned, plus ensuring all settings in the carb are right and the seals etc. are not degraded.A partly blocked exhaust is indeed possible, this could be by a loose baffle in the muffler but unlikely. If you loosen off the exhaust pipe to manifold joint and the car runs better that will confirm a blockage.Of course it could be the fuel pump, a fuel tank blockage at the outlet (eg rust or old tank liner that is failing), condensor, dirty or oily points, or the coil too.0

-

I'll be methodically ruling out the following:

1. fuel pump (bypass w/ 6v electric)

2. fuel tank clog/ blockage (will set up a bypass tank with a hose to the fuel line if needed)

3. ignition (will be installing new coil, points, plug wires--already installed new plugs)

4. exhaust (will cut pipe before muffler--I was planning on having the complete exhaust replaced anyway, so no harm)

Thanks for all the comments, help, and encouragement! I'll keep you posted on my progress.0 -

You may want to install an inline fuel filter to see if your picking up debris from the tank0

-

Re replacing the exhaust pipe, on my '36 Terraplane I ended up putting a larger pipe on right from the exhaust manifold, I think from memory it is 2" to match the size of the manifold outlet, and then with just one bullet muffler under the floor. It doesn't sound too loud at all and must flow better than the original pipe which was one size smaller.tylerwatts said:I'll be methodically ruling out the following:

1. fuel pump (bypass w/ 6v electric)

2. fuel tank clog/ blockage (will set up a bypass tank with a hose to the fuel line if needed)

3. ignition (will be installing new coil, points, plug wires--already installed new plugs)

4. exhaust (will cut pipe before muffler--I was planning on having the complete exhaust replaced anyway, so no harm)

Thanks for all the comments, help, and encouragement! I'll keep you posted on my progress.

0 -

Update:

No change in my acceleration/ high rpm problem. I installed the electric fuel pump and verified solid flow of clean gasoline (ran it w/ hose into a gas can). Checked ignition point gap/ timing (I'm on the 3rd or 4th advance mark w/ timing light), and replaced spark plug wires. Cut the exhaust pipe ahead of the muffler to assure it's not backing up at a clogged muffler. Haven't gotten the new coil, points, rotor or cap yet, but based on how nicely it's starting up and running (other than the acceleration issue), I'm having a hard time believing I have an ignition problem. I'm gaining confidence that I have a carburetor problem. Although I noticed when watching the distributor while accelerating that the engine actually gained some vacuum at first, meaning that the distributor went into more advance while accelerating, before then dropping back into retard as the engine vacuum dropped. It does appear that my jury-rigged replacement vacuum can is working, but again I'm wondering if it's giving the right amount of pull, so I might just bite the bullet and buy the best-looking NOS vacuum advance I can find.

Here's another interesting tidbit that maybe someone can give some feedback on: it seems that every time I accelerate the engine, when I let off it seems to drop to a higher and higher idle speed, such that I need to constantly back out the throttle stop screw. It might just be the throttle stop screw is vibrating itself loose w/ engine vibration at higher speeds... but I'm wondering if it has something to do with carb adjustment--specifically the seemingly complicated linkage connecting the throttle and choke?

As always, any tips or suggestions will be greatly appreciated!0 -

Where did the car come from. Carbs.are set where they were from car that people live in higher elevation the carb is set to that place Car in the mountain the car runs richer due to thiner air then living at flatter land

Just my 2 cents might help0 -

I picked up the car in Flint, MI, elevation 750'. I'm in NW Michigan, elevation 1260', so I only have a 500' elevation gain.0

-

Tyler - is the carburetor recently rebuilt? Have you gone through it thoroughly? Did you check the metering rods to be sure they’re the correct ones for the 212? The metering rod number is stamped on the brass rod. It could be a block vent or jet hole in the carb.I have a ‘46 212 which uses the same car as your 47; the Carter 501s so happy to help with questions

th0 -

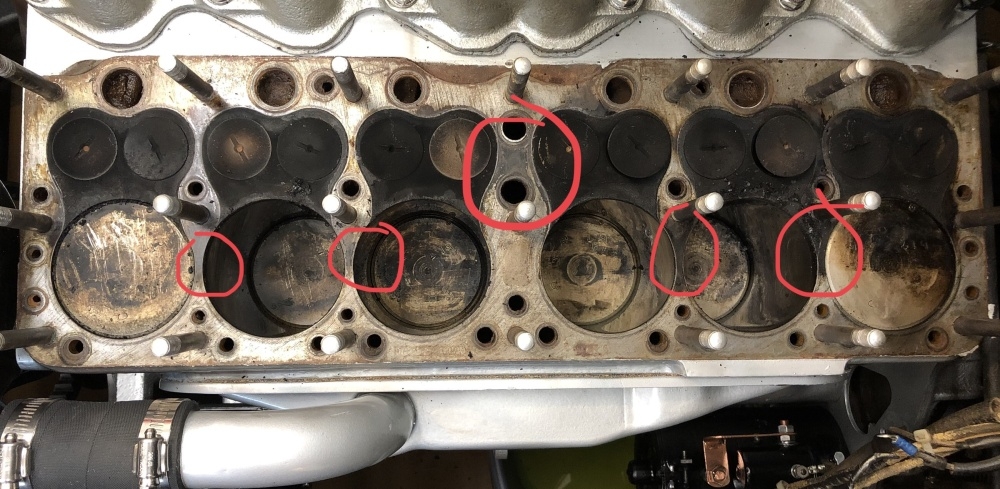

I had issues with my 37’s 212 engine stumbling at different times. When I finally got it running again after 15 years of sitting in my garage, I had stumbling at higher rpm’s. It turned out to be a blown head gasket, pretty much every cylinder leaking.

Video of it stumbling;After it & a lot more was fixed I started driving it but it had a different stumbling driving it. Turns out to have been a cam thrust washer that was missing & it had wildly changing timing as the cam bounced forward & back in the engine.Video of the engine cutting out after initial engine work;

Video of it stumbling;After it & a lot more was fixed I started driving it but it had a different stumbling driving it. Turns out to have been a cam thrust washer that was missing & it had wildly changing timing as the cam bounced forward & back in the engine.Video of the engine cutting out after initial engine work;

https://youtube.com/shorts/ea0Z8leqZ7U?feature=share

With the timing light on the engine one can see how the timing mark jumps around, before repaired;

https://youtube.com/shorts/cA6wP8Kw3Sg?feature=shareDon’t know if any of this helps but ya never know.0 -

Thanks BigSky--I'll look into the head gasket. I watched your videos and mine is acting similar to your first vid--it idles fine, and accelerates fine up to a point, but then really dies at I'm guessing halfway to WOT. I do not have the issue with the timing jumping around, so I'm hoping that means I don't have the cam issue.0

Categories

- 37K All Categories

- 116 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos