Gear Engagement problem - 1934 Hudson 8

I've always had a problem with engaging a gear from rest. Once the car is moving, gears change smoothly - a quick shift up from first to second and a more leisurely double clutch for second to third, as well as a double clutch when changing down from third to second.

I've now fitted a relined clutch and ensured the pedal is adjusted to about 1 inch of play before feeling any resistance but the problem of engaging a gear when the car isn't moving is still there - a noisy graunching sound, even when I let the flywheel slow down first.

With the engine off, I can shift between the gears easily. Also, if I start the car in first and the clutch pedal down there's no problem.

It seems, to my rather ignorant mind, that pushing the pedal may not be moving the thrust bearing assembly sufficiently, although I have adjusted the pedal linkage (using the rearmost hole in the swinging arm - that is, the one closest to the back of the car) to the point where I can't reduce pedal free movement any further - but I'm not sure if this is the true source of the problem.

The thrust bearing assembly has only done a few hundred miles and I lubricate it regularly.

I've tried removing the return spring on the pivoting arm on the side of the transmission in case that was preventing sufficient movement and the graunching is still there.

With that spring removed, there's a bit of play where the cross shaft from the pedal goes into that arm - I wonder if that or something else is leading to lost motion somewhere in between the pedal and the thrust bearing.

To use a cricketing term we Brits often use, I'm "stumped" to think what else might be the cause of this problem and am resigning myself to having to pull the whole transmission out.

Before I do this I'd really appreciate, please, any suggestions as to what might be at the root of the problem.

David.

Comments

-

Does it grind when shifted to second gear at rest?

I got in the habit of going to second then first, worked for me.

Otherwise, I have no advice.

0 -

David - Have you opened up your trans cover to see if you can spot the issue?

0 -

A major issue is alignment of the bell housing and the block, and this is controlled by the dowel at the top and the bolt at the bottom right (as viewed from the driver's seat). This should be a 7/16" shank bolt, inserted from the front. I have seen many installations where a 3/8" bolt has been used, and normal torque reaction will cause the bell housing to move downward slightly, and this will mis-align the clutch input shaft/main drive shaft with the flywheel centre. So do check that bolt, and if it's a 3/8" bolt, replace it. You will have to loosen off the other housing bolts to get the bolt to go through the hole, with a bit of jiggling around to get aligned. If this is not the cause, then you have problem with the plate sticking to the flywheel, or too much fluid in the clutch, causing it to hydraulic.

0 -

Thank you all.

Going into second before putting it into first still graunches although not quite as much - but the noise still makes me wince !

I used the correct size bolt inserted from the front, Geoff, following the advice you wrote in WTN many years ago.

I have the floor out and I'm going to take the trans cover off - I will report back.

0 -

One further thought, the clutch has been relined with Kevlar not cork, as recommended by Australian HET'ers. I had the work done by specialists who do the same cork to Kevlar conversion on pre war MG clutches and, once on the move, the clutch works very smoothly.

The problem only occurs when starting off from idling. It's as though the flywheel isn't slowing down enough.

If there's nothing wrong to be seen with the top off the gearbox, I suppose I'll have to pull the whole transmission out.

0 -

The jury is still out on the Kevlar question. Some swear by it, and others have thrown it away and gone back to cork. It may be that it needs less fluid than cork, so try reducing the amount and see what happens.. Or perhaps it may need a different spec lubricant? Question - did the clutch installer machine a good number of grooves in the lining to allow the lubricant to spread across the face of the disc?

0 -

This is what they did, Geoff. The Australian opinion was that it looked OK.

0 -

...And it's what the specialists do on MG cork/kevlar clutches. The MG Owners Club recommend them too.

0 -

Should be okay then. When you have the top off the box, depress the clutch and see if the input shaft stops turning. If not, increase the throw of the fork ( less pedal clearance to the floor), and see what happens. What oil are you using in the gearbox? Good luck.

0 -

The gearbox oil is SAE90 GL-1. I can't get a yellow metal friendly SAE80 in the UK.

The oil in the clutch is Dexron III automatic transmission fluid - I've checked with the clutch re-liners and they've checked with the manufacturer of the Kevlar they used for my clutch and say Dexron III is OK as a lubricant.

I've used 1/3 of a pint (imperial measurement) up to now but some sources say 1/2 US pint, which is 8 fluid ounces (therefore, a little bit more than I've been using). I'm going to put new Dexron in, how much should I use, please, Geoff ?

When we put the clutch back in my Rolls Royce engineer friend was careful to use NOS clutch fingers and took several hours to get them set up properly.

Tomorrow, I'll see whether I can increase the throw of the fork a bit more. I have already taken it up to just 1 inch play at the pedal and that has allows me to get in first when idling if I go into second (slight graunch) and then reverse before engaging first. It still graunches but not quite as much !

0 -

I would experiment with a slightly smaller quantity of clutch fluid, and also bring the clutch pedal further out. Kevlar i a different material entirely to the original corks, so you won''t be affected by heat swelling, so 1/2" clearance at the floorboards will be fine. Also check that you have the link in the inner hole of the throw-out lever, to give greater movement.

0 -

Thanks Geoff, I'll try that.

By inner hole in the lever, I assume you mean the one nearest to the back of the car - which is the one I'm attaching the pedal yoke to.

0 -

No, the top one. There are three holes. Use the one closest to the pivot point.

0 -

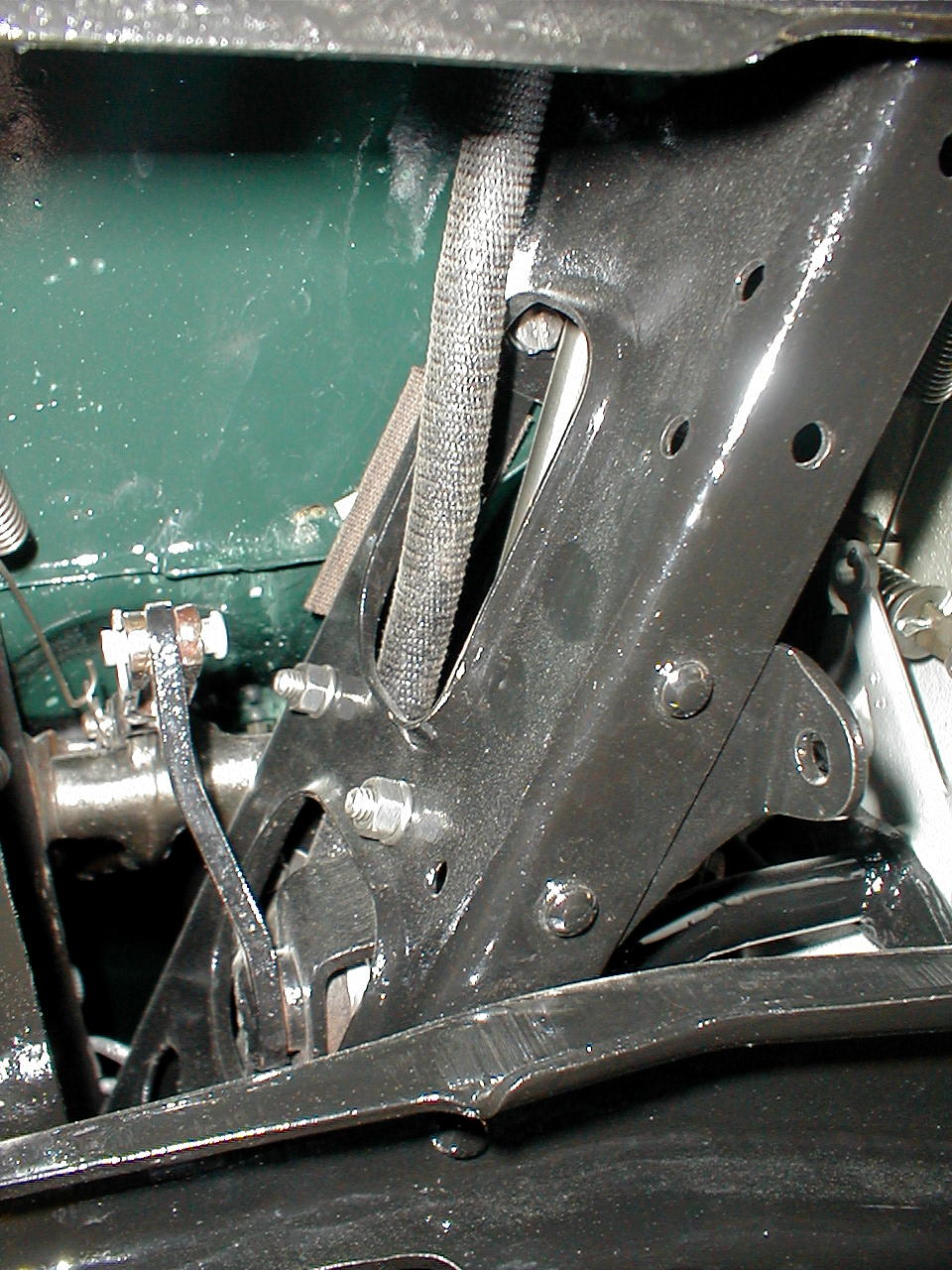

Geoff - please have a look at the attached drawing - do you mean the far hole from the one I'm using ?

Using any hole other than the one I'm using, gives no resistance to the pedal and no movement of the lever on the side of the bell housing.

0 -

Move the yoke to the hole closest to the pivot shaft ( to the right in the drawing). This will give more movement to the throwout.

0 -

Thanks, Geoff.

My friend "Rolls Royce" Bob is coming over to me this evening and we'll have a go at adjusting the mechanism properly - it's going to be easier with 2 people (particularly with one of them knowing what he's doing !).

As things stand, I think your theory of the throw out bearing not moving far enough forward is most likely correct.

0 -

I've been following what this pic shows and thought it was right, Geoff. I'll try the hole at the other end.

0 -

Geoff,

I have managed to get the clutch to operate properly using the hole at the other end of the swinging arm as you suggested.

I had to do away with the lock nut on the yoke to get the yoke to wind up far enough - but when everything's assembled, the lock nut seems superfluous in any case.

I also installed a weaker return spring on the arm attached to the transmission housing.

The pedal now feels less "spongey" than it was before, as well.

I will take up your suggestion of trying exactly 1/3 US pint of Dexron 3 ATF in the clutch and see how I get on when I take it out for a test run on Sunday.

Thank you again for all your help, I will report back after Sunday...

David.

0 -

Probably the gasket is too thin. But easier to relocate the pin on the throwout than to replace the gasket. Not a good idea to have no lock nut as it is then working on the thread. Perhaps turn a nut down thin on a lathe, or even us a palnut. You could also try using the intermediate hole and see if that gives enough throw to free the clutch when the pedal fully depressed.

0 -

Thanks Geoff, I spoke to Bob this morning and he thinks I've probably gone a little too far with reducing pedal play to 1/2 inch so I'm back under the car this evening to slacken things off a bit.

I'll give the middle hole a go and will certainly fit a slimmed-down lock nut.

I will report back.

David.

0 -

If you still cannot fit a lock nut/palnut, permatex blue thread locker will work as well.

regards, Tom

0 -

Thanks for the tip, Tom. 😊

David.

0 -

An update from me.

I adjusted the pedal to 1 inch of play before meeting resistance and starting to move the bearing forward, as well as filling the clutch with exactly 6 fluid ounces of Dexron III.

After a couple of Sunday trial runs, I'm pleased to say that first gear is easier to engage ( adjusting the tick-over helped here too ) and I don't get clutch slippage followed by judder and then snatch when I change up into second gear on a slope.

So - fingers crossed - it looks like all is now OK.

Thank you very much Geoff, Tom, Todd and Lostmind for all your advice.

David.

0

Categories

- 37K All Categories

- 104 Hudson 1916 - 1929

- 19 Upcoming Events

- 91 Essex Super 6

- 28.6K HUDSON

- 559 "How To" - Skills, mechanical and other wise

- 993 Street Rods

- 150 American Motors

- 173 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 599 Vehicles

- 2.1K Parts & Pieces

- 77 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos