262 Engine Refresh/Overhaul Project

IvarSweden

Senior Contributor

I'm in the process of restoring my 1948 Hudson Commodore with a 1950 262 six and manual overdrive transmission. Today I removed my timing gear cover to check my timing chain and decided it needs replacement. It is stretched but not as bad as BillUSN1's in his project creep pictures.

I had some problems removing the vibration damper. First of all, the washers didn't look right and the manual says something about a lock, which I don't have? The timing cover spacer looks pretty bad but I'm getting a new one from 21st Century Hudson. The woodruff key for the vibration damper was also very worn, probably from the engine running without the screw tightened properly.

I used a large puller to remove the vibration damper but had to use a lot of force because of some pretty bad galling. The crankshaft is harder than the vibration damper so not as damaged. The question is, would you use this vibration damper or try to find a better one? Maybe it doesn't matter once it's fitted?

I had some problems removing the vibration damper. First of all, the washers didn't look right and the manual says something about a lock, which I don't have? The timing cover spacer looks pretty bad but I'm getting a new one from 21st Century Hudson. The woodruff key for the vibration damper was also very worn, probably from the engine running without the screw tightened properly.

I used a large puller to remove the vibration damper but had to use a lot of force because of some pretty bad galling. The crankshaft is harder than the vibration damper so not as damaged. The question is, would you use this vibration damper or try to find a better one? Maybe it doesn't matter once it's fitted?

0

Comments

-

Get a better one. It shouldn't be hard to find.0

-

Wow, that is a pretty ugly one. If you can't locate a better one, you could dress off the high spots so as to not induce galling upon re-installation but if the keyway is at all "hammered out", your only solutions are to broach a new one or replace the hub and/or the whole dampener. Use a "press-fit lube" upon re-assembly, like Sunnen B-200.

The washers in the photo may indicate that the previous mechanic wasn't aware that the attaching capscrew (bolt) must not bear on the body of the pulley. By design, it should only tighten against the hub....that portion with the keyway cut into it. Those two parts are intended to move independently of one another with crank torsional vibrations and utilize the internal rubber discs to achieve the dampening effect.

Frank

0 -

FYI

Try to find another Dampner like suggested above. Mark the pieces then unbolt the back to make sure the inner hub pieces are clean then assemble and install onto the crank using Red Loctite. ... Not being a Hi Performace application, perhaps file the high spots in your Hub then re install

with Red Loctite....

0 -

Ok, I'll try to find a better vibration dampener. The key was very loose in the keyway but the old key was very worn so I need to try a new one before I know for sure how much play there is. I'm buying a new timing chain kit from 21st Century Hudson and hopefully they have a good used vibration dampener to sell.

Another question, I seem to missing quite a few parts behind the timing chain cover. I don't have an oil trough and no timing chain shoe, like I've seen in BillUSN1's project creep pictures. There is just one screw that I don't know what it's for? I have some nasty looking marks on the inside of the timing cover, forgot to take a picture tonight but will tomorrow.

0 -

FYI

I think 21st Century will have everything you need and think his Timing Sets have new Woodruf Keys.... If not Keys are available at any Tractor or Heavy equipment Dealer Parts Counter.. I have Dampners but their heavy to ship.

Dont think early Models had the Chain Shoe yet... The Chain 'Througth' and small pcs are available from Dave Kostansek in Oh too.440 293 4079

0 -

Let us get together everything you need for this project. Randy & Russ @ 21st Century

0 -

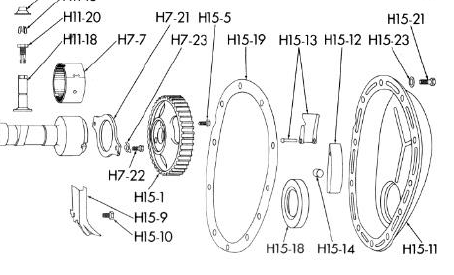

I looked in the Master Parts Catalogue and all the small parts are listed from 48 through 7D. The engine is a 1950 262 narrow block.

The following parts are missing from my engine. What are they for, do I need them?

H15-9 Trough-oil

H15-10 Screw-trough attaching

H15-12 Shoe-timing chain cover

H15-13 Rivet-timing chain cover shoe

H15-14 Bumper-timing chain cover shoe

I have these nasty looking marks on the inside of the timing cover.

Can also be seen from the outside..

0 -

Looks like somthing came apart inside and banged against the housing. Probably some of the missing parts.0

-

We will send you a good cover along with everything else.

Randy Maas

0 -

I removed the cylinder head today because of the problems I've found so far. Unfortunately two head bolts sheared off in the process, it shouldn't be that hard to get them out though.

I found the exhaust valve on #1 cylinder stuck partly open. I soaked it in WD-40 and tapped it very gently with a rubber mallet until it was fully closed. After a couple of times it now looks like the spring closed it. Some valves have quite bad surface rust and they have different markings. Some of the inlet valves say IN, other INL and some nothing at all. If I install a set of stainless steel valves and new valve guides, I can run on unleaded fuel?

0 -

I would also replace the springs and guides. Check the lifters to make sure they are not worn on the top where the valve stem contacts them. They can be resurfaced, but replacements are available through Dale Cooper.0

-

We also have valve guides, springs, lifters, valves at 21st Century Hudson

0 -

Maybe hard to tell but the valves look a bit tired to me. I'll try to find a valve spring compressor that works and remove them to have a look at them and the seats.

0 -

I renamed this thread, it will be an ongoing project for the coming weeks/months.

I removed all the valves yesterday, it was surprisingly easy. I don't quite understand how the valve springs are supposed to go back in though, being longer than the space they go into. I'm thinking of compressing the valve springs and fitting a few high quality tie wraps to hold them compressed while I fit them into the valve spring compressor. I can then cut the tie wraps in place, anybody tried something like that?

I found the reason why #1 exhaust valve was sticky, the valve guide top was split! I don't understand what caused it, needs new valve guides for sure.

The valve seats look OK from a visual inspection, no cracks that I can see. Some of the valve seats have some surface rust so need to be recut.

0 -

Iver,

You should try and find someone local that is experienced at this to help you out. Obtain the Hudson maintenance manual or download it from the HET club site, you will need it for the info your are asking and more. The manual has fairly good pictures as well. The Hudson Parts Manual would be a help as well as it has parts illustrations.

The valves are put back in by using a valve spring compressor. The keepers (two little locks that should have been there when you pulled each spring) are a little tricky to install sometimes.

Have you pulled the oil pan yet?

Do you have a local machine shop that can thoroughly clean the block after disassembly and after any needed machine work?0 -

Hi Kerry, I have downloaded the maintenance and parts manual. I just find the manuals short on information, for instance I can't find a word on reinstallation of the valves. I've worked on engines all my life, just never a flathead engine before. You are right, I do need local help to complete this engine.

The engine is out of the car and the oil pan is removed.

0 -

Looks like your heading down the same "Project Creep" that I did with my 262.

I tried to show every step I went thru but if there's some specific just ask.

You could probably use some tie straps but it may take more time then it's worth. The spring has to go over the guide and the lifter and it's longer than the remaining space between the 2. IIRC I simply stuck the spring over the guide and then used a short pry bar to pop it over the lifter.

Then installed the compressor.

I tried a pair of the valve keeper installers and they did help during install on some of the springs. There should be pics of them as well in my thread(s).

I think almost everything I did in my thread will apply to yours.

I did not remove the pistons during my repairs.

I did remove everything else, cam, crank...etc.

0 -

Here is Bill's engine build thread. it shows the valve spring compressor tool.

http://openforum.hetclub.org/discussion/165555/project-creep-valve-guides-valve-job-etc/p1

0 -

looks like your block should have a good flushing. Your going through all this you should make sure your water ports are all clean.0

-

cvs, I guess you're right. Do I need to remove all the frost plugs to flush it properly?

0 -

Parts and down time aren't getting cheaper. A evenly cooled engine should be just as important as the other particulars. I feel it's money well spent.0

-

Also, pull the cylinder water distribution pipe to flush out trapped sludge.

Lee O'Dell0 -

Lee: I tried to pull the water distribution pipe but only tore the brass tab so there's nothing left to pull on. It's really stuck in there, I sprayed some WD40 on it and will try again next time I go to the garage.

Some progress!

I've disassembled the vibration dampener, it was quite easy actually. Everything looks fine except the center part. I've talked to a local Hudson nut who has a cracked welded vibration dampener with a good center I can have to replace my bad one.

I got the radiator back from recoring. Annoyingly the guy has straightened the top tank by making numerous protruding dents, it now looks way worse than before.

I received the oil pump/distributor alignment tool from HET member Gert Kristiansen.

I removed the camshaft to measure the lift/wear and be able to remove the tappets. It's a 304078, lift measurement showed consistently 0.350" and no visible wear.

The adjuster side of the tappets are all worn, can't see anything wrong with the cam side. Can these be machined without removing the hardening? Do I need to keep the tappets numbered and reinstalled in the same place?

0 -

These are hard all the way through, not case hardened. Go ahead and reface them.0

-

FYI

If plan on re-using the same cam its always wise to number them in original order because the tappet & lobe have mated together. Do Not surface the bottom of the Tappets because they have a 'slight Radius to help the Tappet rotate....If already mixed I would buy a tube of 'Cam Assembly Lube' to coat the surfaces. (Actually, I would coat the surfaces even if kept in order).

0 -

Ok, I'll get the adjuster ends resurfaced and number the tappets for reinstallation!

0 -

Some progress: I've removed the crankshaft, pistons and conrods for inspection. The main and rod bearings all say 010 so the crankshaft has been turned at some point.

I tried to look for a date stamp on the bearings, the rod bearings say 73 010 and CB 336M. Could it be 1973? I googled CB336 and Monmouth bearings comes up.

The bearings were in surprisingly good condition, some minor wear from particles in the unfiltered oil. The crankshaft journals have some raised metal and grooves for the same reason. I've ordered some Plastigage which should arrive by the end of the week. If the clearances are good I'll at least keep the main bearings, they look as good as new. Considering the low cost of rod bearings it makes sense to replace them regardless.

I've removed one valve guide so far, thanks to BillUSN1's informative thread. I need a more suitable drift to get the guides moving, the one I've used is too small to be effective.

I've measured the piston ring gap by installing a compression ring about 1" down the cylinder. The gap is about 0.025" so I'm replacing all the rings.

0 -

Special thanks for contributing all the work, writing the text and pictures to this post along with the other posts that it lead to. (project creep)! I really enjoy looking at the pictures and reading about the work that goes into engine rebuilds. I have rebuilt quite a few flathead Ford V-8s myself and I always like doing them. I'm looking forward to doing a Hudson six someday, but only when I can find someone who will mentor me through! This is surely going to become a "lost art" in the near future, as the older guys who have performed this work are more and more rare.I especially love seeing the posts from all of the "old hands" who have obviously been there before.0

-

I removed all the valve guides today, a heavy brass drift and a sledge hammer was all it took. With the camshaft and lifters removed there was no problem to drive the guides downwards.

The sticky valve guide looks different to the others, it has what looks like threads and I pulled out what looks like a thread insert. I could barely pull the valve out of the guide by hand when I disassembled the engine.

0 -

Looks knurled.0

This discussion has been closed.

Categories

- 37K All Categories

- 116 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos