262 Engine Refresh/Overhaul Project

Comments

-

Time for an update!

I brought my engine block to a machine shop in december, to hone the bores and machine the cylinder head basically. They had a look at the engine block and found it had already been bored 0.060 and had two cylinder liners put in. The bores were all a bit worn, especially the cylinder liners. These were probably put in because of cracks between the valve seats and the bores.

I was offered to buy two 262 engine blocks, with crankshafts, pistons, rods but no cylinder heads. I loaded them up and dropped them off at the machine shop.

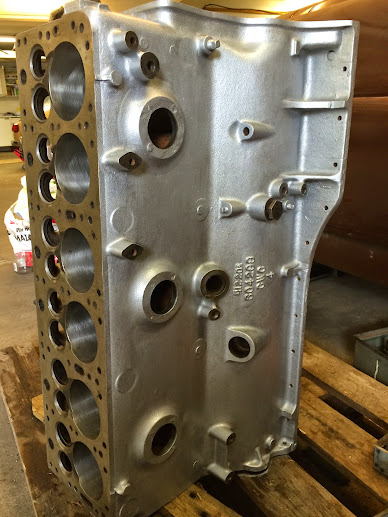

Turns out one of the engines is a 262 and the other a 232. They bored the 262 block 0.060 to fit my pistons, when they found cracks between the bores and valve seats. This leaves me with the 232 block, which as far as I can understand is identical with the 262 block? Can somebody confirm this?

0 -

FYI

The Block is the same just the crank stroke is Shorter. Different Year 232 and 262 block's 'Externally' may be different width but internally their same dimension.

Actually, in the past ive had the tiny cracks between the cyl & valve seat fixed in some different ways over the yrs with no problem afterwards. Cracks occur from different reasons probably over heated a gew times, aging stress, and/or the copper water Distribution Tube may be plugged. What ever block you decide on be sure to pull out the distribution Tube to ensure the holes are open. (Incidently, Ford Merc Flathead V8's are notorious for cyl to seat cracks and what ive read online disregard a minor crack and repair larger ones). Shop's seldom discard the block unless cracked severely.......

0 -

0 -

Duplicate0

-

You should probably check the block width as there are 232 and 262 engines in both narrow and wide. The narrow 232 is a one-year-only engine. They are all the same internally (excepting, of course, the crank.). Heads are specific to each.

F0 -

Thank you for all the replies. Both blocks have casting number 304299, which is why I thought both engines were 262. Both are wide block, 51-54, I've now read 232 and 262 wide blocks were the same casting numbers. I'm hoping the 232 block is crack free! I'll check the water distribution tube and probably pull all the freeze plugs to check for crud?

0 -

If the cylinder bores would only have minimal wear, I would hesitate boring any Hudson block more than necessary to true the cylinder walls.. In fact, in my lifetime, I have found that usually all that is necessary is a miner honing of the cylinders to make ready for new rings.

0 -

The 232 block was crack free and is now bored 0.060", to fit my oversize pistons. There was some pitting in the bores that just cleared at 0.060".

I managed to pull out the water distribution pipe from both the cracked 262 and the 232 block. I'd like to use the 262 pipe, the lower one in the pictures. Any thoughts on this?

0 -

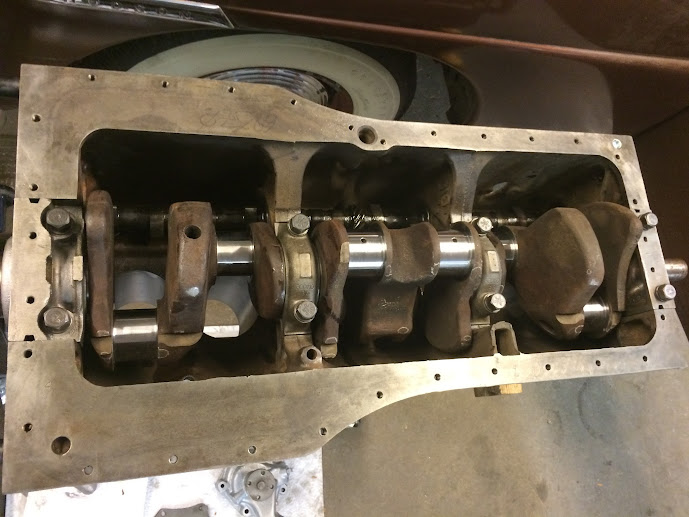

It may be obvious, but You're going to have to use the 262 crank to make your pistons fit, as the rods are the same for the 232, 262, and 308.

The pin positions are all different ie: the 232 pin center to top is 2.310 to 2.314, the 262 is 2.060 to 2.064, and the 308 is 1.967 to 1.971, so you have to keep the cranks and the pistons together.

0 -

I'm using the 262 crank, I also noticed the pistons were different. What about the water distribution pipes, they do look different but may be different year designs?

0 -

Thank you for the information, I will try to keep this picture uploaded for future reference!

0 -

My oil pressure relief plunger/piston is rusted stuck inside its bore. The spring actually broke when the hex cover screw was removed. Has anybody experienced a stuck plunger/piston and can give me advice on how to get it out? I've soaked it in WD-40 for a couple of weeks now. Thinking of drilling a hole in the center and trying to pull it out with a slide hammer.

0 -

I used a tap and threaded the ID. Screwed a bolt into the pIs ton and used it to connect a slide hammer. Piston came out after a few slide blows. Cleaned bore with crocus cloth. Replaced Piston and spring with good used item.0

-

I ran an M16 tap into the piston and after a few turns it broke free and came out along with the tap. The bore wasn't too bad, it was mainly crud rather than rust holding it in place. The oil gallery was quite nasty but I think I managed to get the oil deposits behind the piston out. Started to prepare the engine block for new paint today. Can anybody tell me when this engine block was cast, from the number "H220"?

0 -

Glad to hear of your success0

-

August 22, 1950,0

-

Thank you Ric for helping me decipher the casting date! The cylinder head has the same format: "J100" so October 10, 1950.

Progress is a bit slow at the moment, I've painted the engine block and cylinder head. Makes a big difference in appearance and nicer to work on a shiny engine than a rust brown one. Only missing cylinder head gasket, main bearings, rod bearings, freeze plug set and new cylinder head bolts. Will stop by Dale Cooper in Ohio to get the last parts needed to complete the engine rebuild.

0 -

I finally have all the parts necessary to put the engine together. Today I installed the camshaft, tappets, new valves, and new valve springs. It all went surprisingly well, the last valve took probably 3 minutes to install. I ran thread taps through all threads in the cylinder block and they all look fine.

I'm still not sure about how to install the no 1 and no 4 main bearing caps. I have the neoprene seal from Dale Cooper and he also sent a mop string to go where there used to be wooden inserts. Can somebody describe in words or with pictures how the best possible seal is made? Do I fill the voids with RTV, push the mop string into it before I slide the bearing caps in place? Do I just install the neoprene seal halves without any RTV in the grooves?

0 -

0 -

Have an extra wide block compete '262 engine, less head and water pump, for sale @ $200. Up on blocks, pulled when running over 20 years ago, always inside storage.0

-

Nevada Hudson. is the block still for sale? redder0

-

redrider0

This discussion has been closed.

Categories

- 37K All Categories

- 116 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos