35 T tappet adjustment

Comments

-

Thanks Barry. I'm checking into a few possible sources with bated breath. It seems the folks Down Under have a good supply of older parts. I know you got creative keeping the rolling stock alive during and after WW20

-

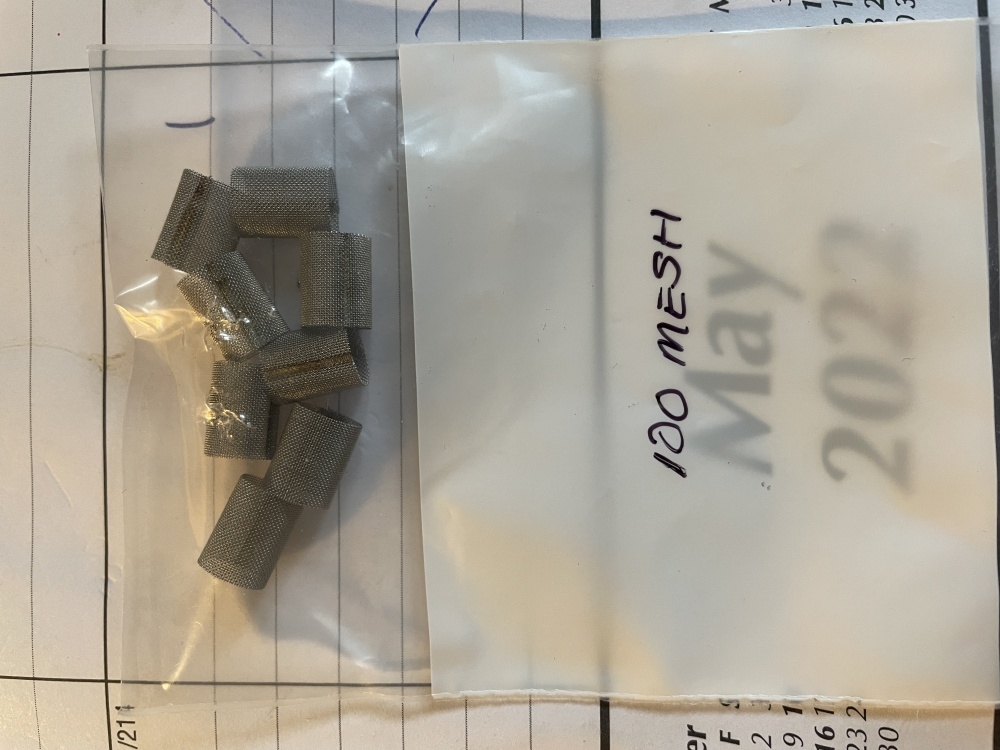

Heres pics of the check valve, screen & plug cap. The screen fits snug on the shoulder of the valve & snug in the bore of the plug cap. Kinda like it grew there.

0

0 -

Tom. Check with this guy: https://www.thecarburetorshop.com/PartsCarter.htm0

-

I’ll check to see if I have one on one of the parts carbs I have this weekend0 -

Toddh Thanks for the offer. I think I have a line on one but won’t find out until at least next Tuesday when I get back home. Out of town until next Tuesday0

-

Back to it after the winter hibernation and a few other projects.

Got the gas tank sealed with Red Coat. Got new Cunifer fuels lines.

Searched the web and found a company in MI that made filter screens for industrial applications. I emailed them with the dimensions & pics of what I was looking for and what the application was. I received a reply asking for my mailing address. A few weeks later these showed up in the mail with a note saying they are metric but almost the same size I’d asked for. They fit well and are stainless steel. Also said they were glad they could help out and provide them as samples. WOW. I offered payment but they refused. I replied thanking them for their generosity.

I’d earlier posted pics showing the float set at 1/2” after I had it rebuilt. The rebuilders also had two gaskets under the float bowl cover. Not sure why. I acquired a third carb with the same float bowl cover. I checked all three covers I now have and all have a slight warp in the same area between the marker ticks in the attached pic. I can get an 0.014 feeler in the gaps so not to bad. I checked the top sealing surface of the float bowl flange with a piece of glass and it appears to be dead flat.

Now to a question.

I plan on using only one flat bowl gasket and setting the float to 3/8” per the spec sheets Todd had provided.

The float bowl is open to atmosphere around the plungers & metering rod. Would it be advisable to put a slight smear of aviation fuel sealing on the float bowl gasket in the area of the warps?

As always, any help is greatly appreciated.

Tom0 -

can anyone tell me what carb this metering rod is used for?

0 -

A pic looking down thru the fuel gauge flange after the "Red Coating" the tank. Cleaned to outside and painted. Didn't clean the filler neck as what ever the original coating was on it didn't want to come off.

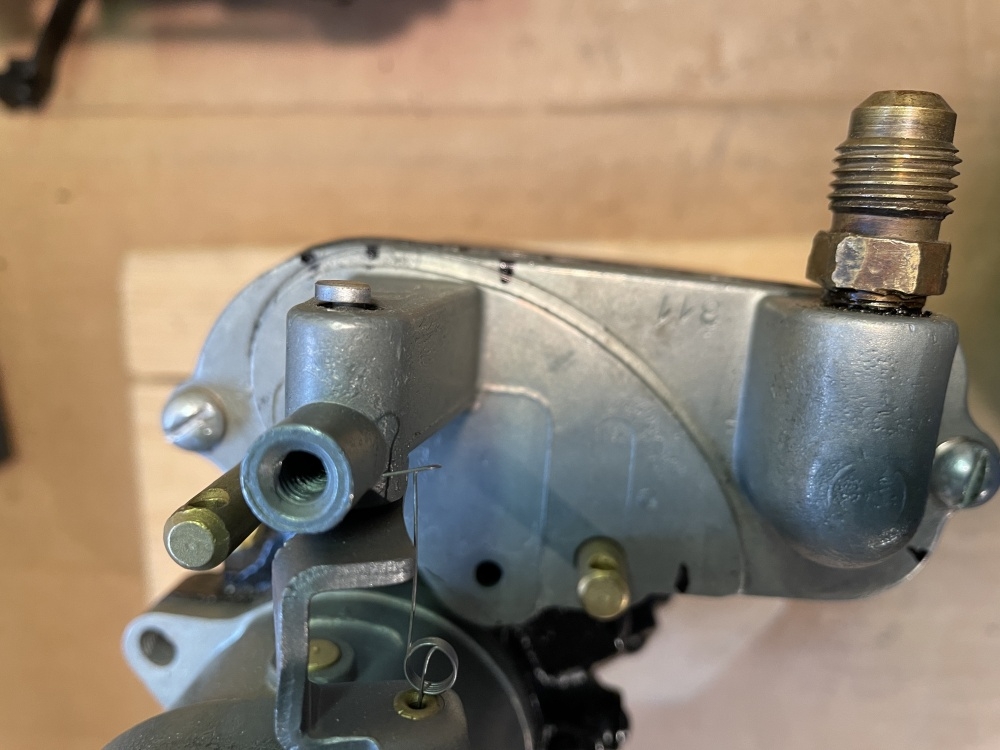

Had leaks in two of the brass plugs in the carb body. The one I'm pointing to and the one under it. Of course nicked up screw slots trying to tighten them up. Called the rebuilder. They sent me new copper seals and said to apply a small drop of blue Loctite to the threads. Worked. Asked them about the 1/2" float height. They said it was due to the different seat & needle they use and with those the 1/2" was good. Took the seat & needle out of another carb. When installed the float height was 3/8". Reinstalled the rebuilders seat & needle and the float height returned to 1/2".

Had leaks in two of the brass plugs in the carb body. The one I'm pointing to and the one under it. Of course nicked up screw slots trying to tighten them up. Called the rebuilder. They sent me new copper seals and said to apply a small drop of blue Loctite to the threads. Worked. Asked them about the 1/2" float height. They said it was due to the different seat & needle they use and with those the 1/2" was good. Took the seat & needle out of another carb. When installed the float height was 3/8". Reinstalled the rebuilders seat & needle and the float height returned to 1/2".  Once installed she fired right up and ran smooth. Happy Days are here again. 0

Once installed she fired right up and ran smooth. Happy Days are here again. 0

Categories

- 37K All Categories

- 116 Hudson 1916 - 1929

- 21 Upcoming Events

- 96 Essex Super 6

- 28.6K HUDSON

- 576 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 181 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 609 Vehicles

- 2.2K Parts & Pieces

- 78 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos